Fume filtering element used inside kitchen ventilator

A range hood and oil fume technology, applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., to achieve the effects of energy saving, simple manufacturing process, and convenient use and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

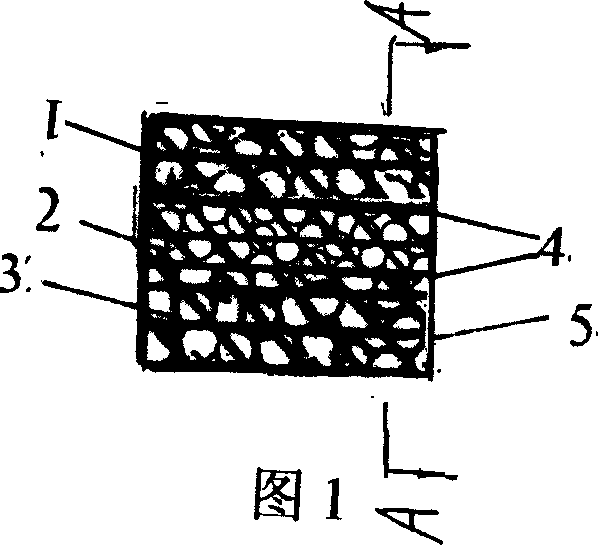

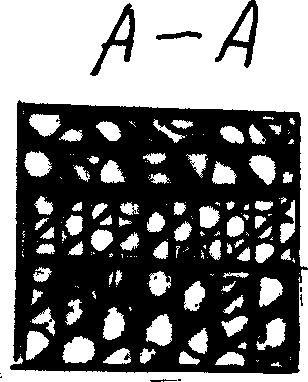

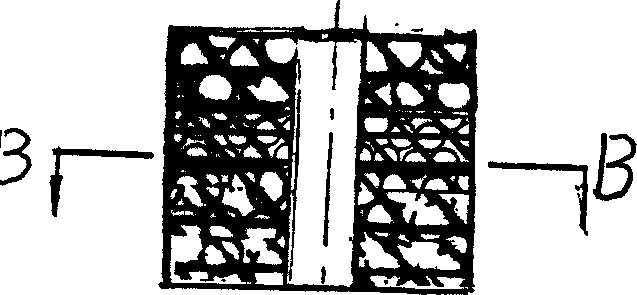

[0014] From Figure 1, image 3 An example of the present invention is given: a lampblack filter element used in a range hood mainly consists of three layers of high-efficiency adsorbent materials, and its specification is that the upper layer 1 is an inorganic polymer coke activated carbon adsorbent material with a diameter of 2-3cm ; The middle layer 2 is a carbon molecular sieve adsorption material with a diameter of 1-3cm; the lower layer 3 is a coke activated carbon adsorbent material with a diameter of 3-4cm. image 3 It is an oil fume filter element with a hole in the center.

[0015] In specific production, according to the raw material ratio of each component adsorbent required for making a 1000-gram oil fume filter element, it is calculated as:

[0016] Upper activated carbon adsorbent material 250-350 grams

[0017] Middle layer molecular sieve adsorbent material 150-250 grams

[0018] 350-400 grams of activated carbon adsorbent material in the lower layer.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com