Protein and polymer as pith and stickies control agent in pulp and papermaking processes

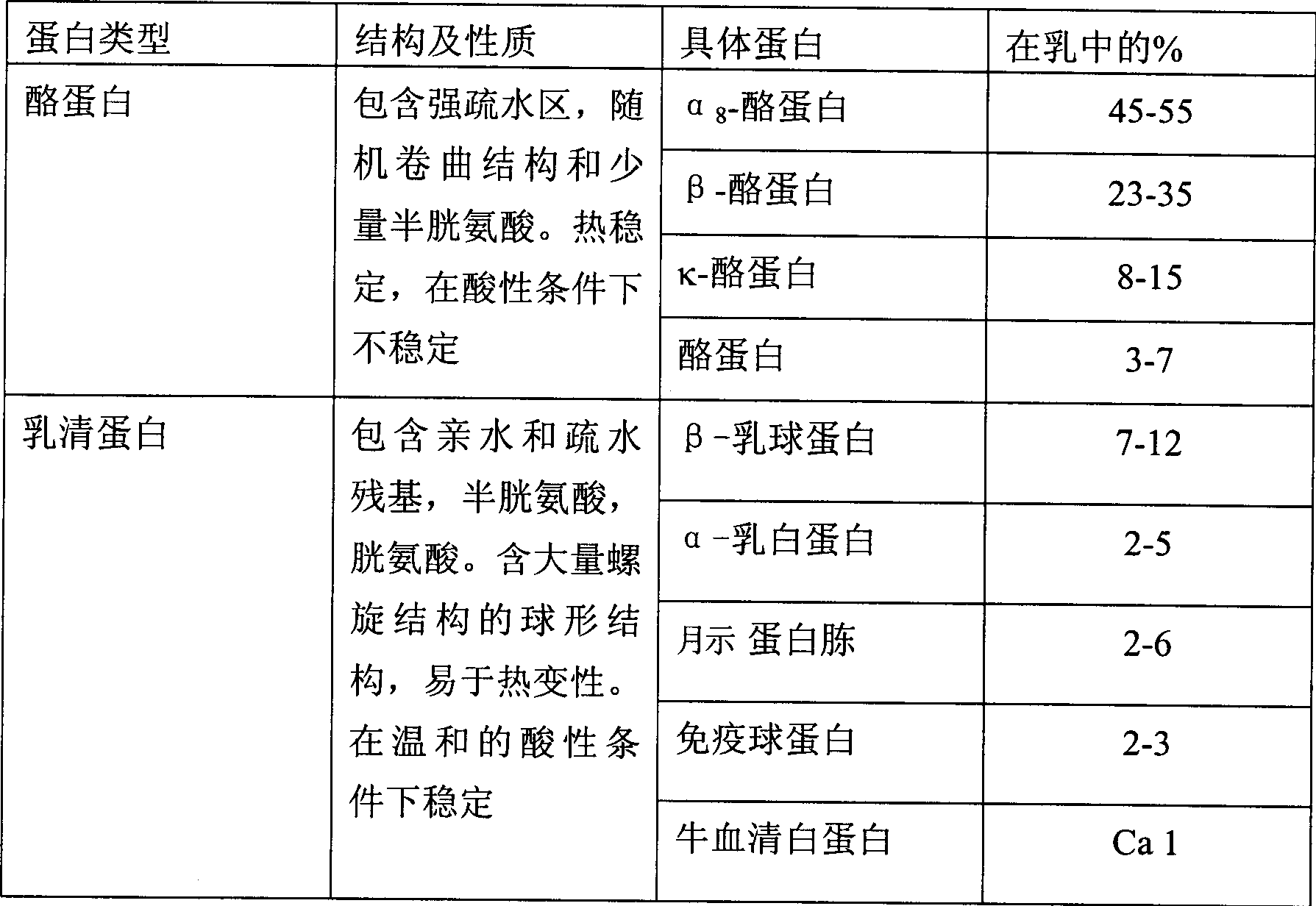

A technology for pulping and viscose, which is used in textiles and papermaking, fat/resin/bitumen/wax removal of pulp, papermaking, etc., and can solve the problems of undisclosed physical/chemical properties and poor performance of milk protein.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Standard Tape Detack Test (STDT)

[0048] To determine the effect of the compositions of the present invention as deposition control agents on sorted adhesive contaminants on plastic surfaces, especially found in recycled paper pulp, a laboratory was carried out using adhesive backed tape as an adhesive coupon. test. The adhesive samples can be made from any type of tape that does not break down in water. For this study, tapes made from styrene-butadiene rubber and vinyl ester were used. These two potential organic contaminants are known to cause viscose problems in secondary recycled fibers. The second sample was made from a polyester film such as MYLAR, a product sold by the DuPont Chemical Company of Namur. This material was chosen because the construction of paper machines is usually made of polyester, which is believed to be susceptible to deposition problems caused by glue and / or resin.

[0049] The test involved immersing a 2"x4" tape and a 2"x4" polyester My...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com