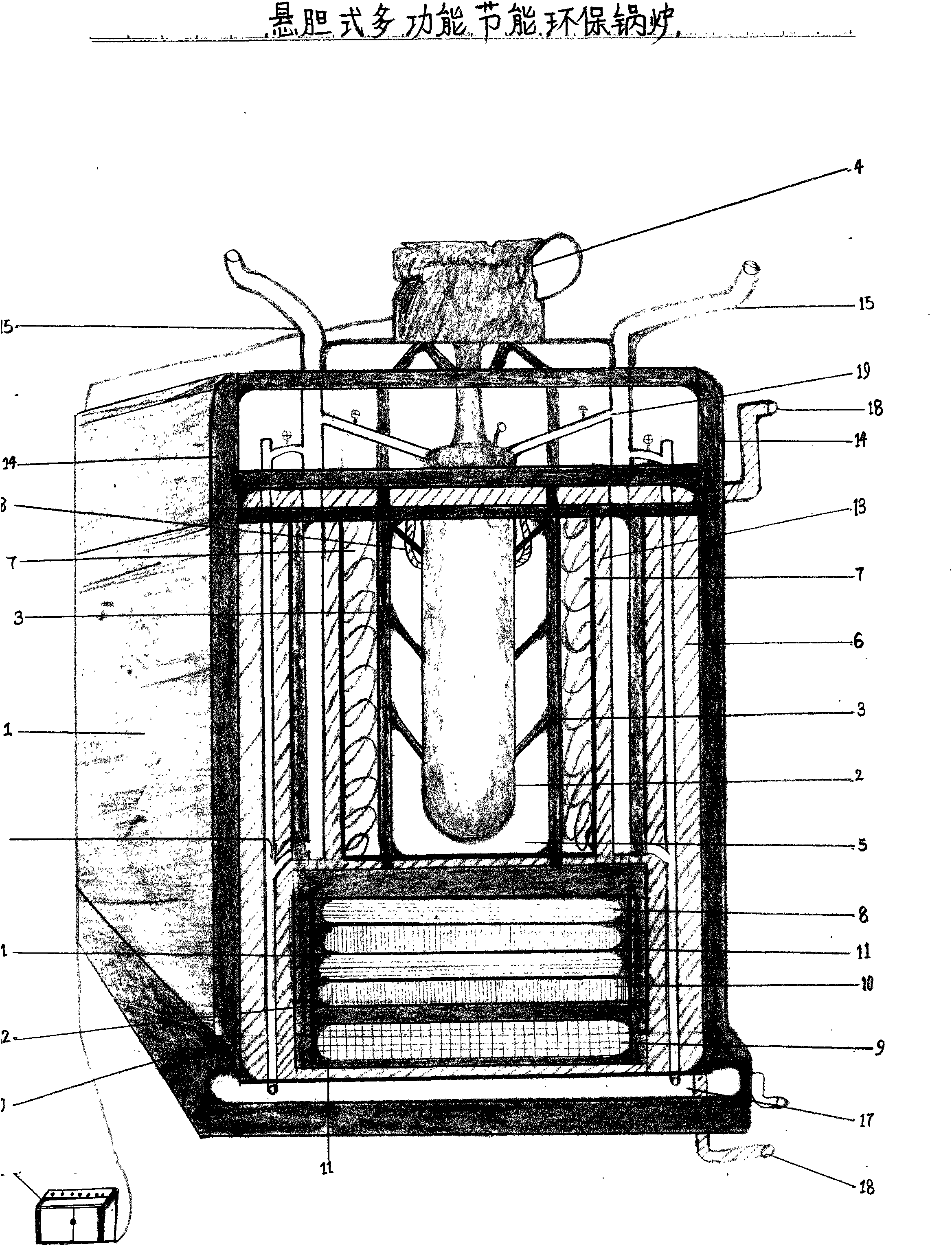

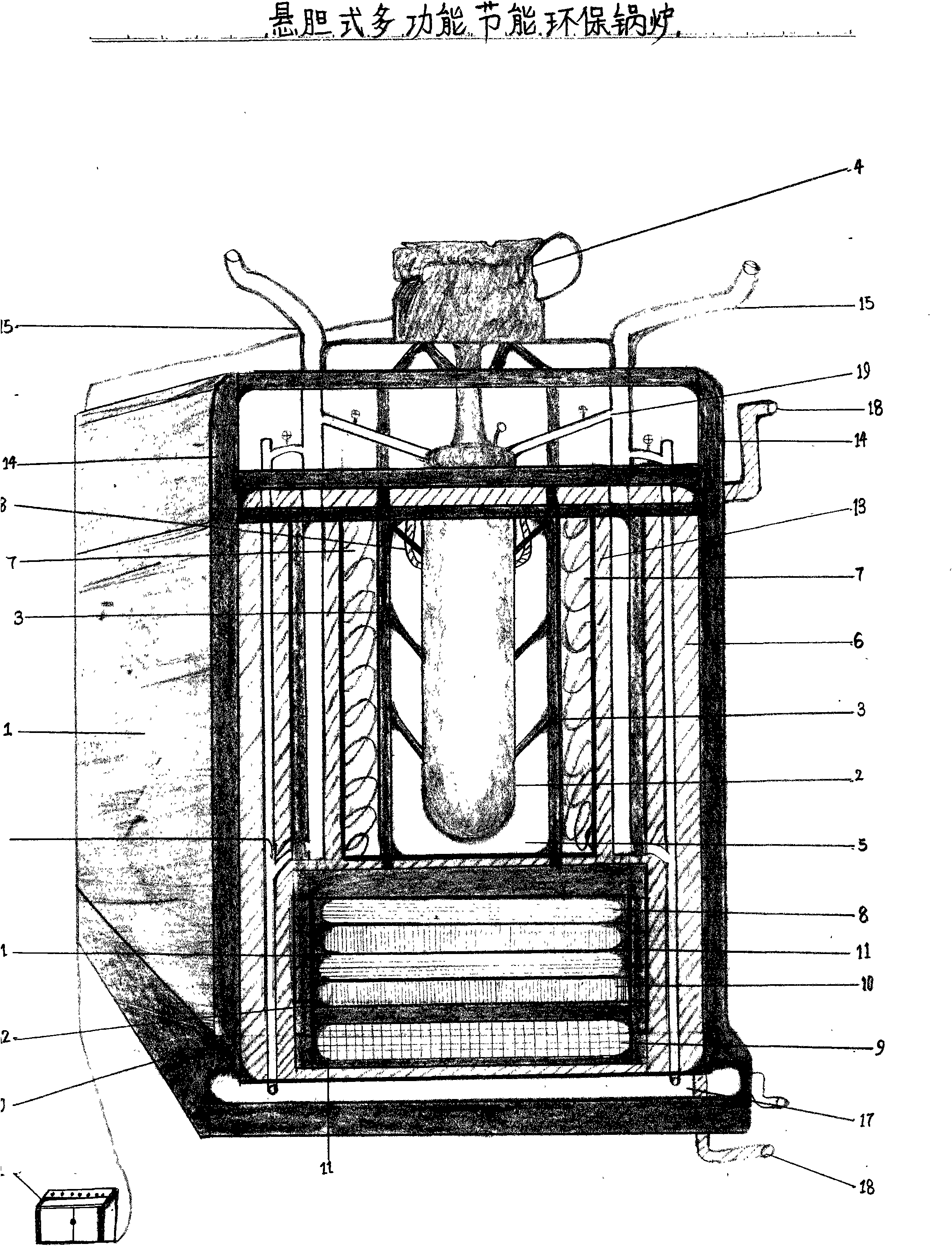

Suspension bladder type multifunctional energy-saving environment-friendly boiler device

An energy-saving, environment-friendly and multi-functional technology, which is applied in steam generation devices, biofuels, steam generation, etc., can solve problems such as large water consumption, waste of resources, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation of each system of the hanging tank type energy-saving and environment-friendly boiler of the present invention is as follows:

[0032] 1. The honeycomb briquette in the boiler combustion main furnace heating bin is extracted 8 from the upper layer and 9 from the lower layer to provide main heat energy for boilers 2, 3, 4, 5, 6, 7, 11, 12, 13, and 19, and the middle building Profile auxiliary combustion extraction tray 10 provides auxiliary heat energy for the boiler, and boiler 18 provides circulating cooling water source for boilers 11 and 12, and in turn, boilers 11 and 12 can provide normal pressure flow for boilers 2, 3, 6, 7 and 13 softened water heat;

[0033] 2. Suspended gallbladder-type high-pressure steam boiler, which provides power generation power for the steam ram turbine generator 4 and is connected to the circulating water pipeline inside the boiler. The circulation pipeline in the boiler provides steam circulation and softene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com