Semi-attraction float type magnetic suspension drive system for superfine machining

A technology of ultra-precision machining and drive system, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc. It can solve the problems of control system oscillation, complex devices, and low dynamic friction coefficient, so as to reduce dynamic and static friction , Improving the feeding accuracy and stabilizing the displacement field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

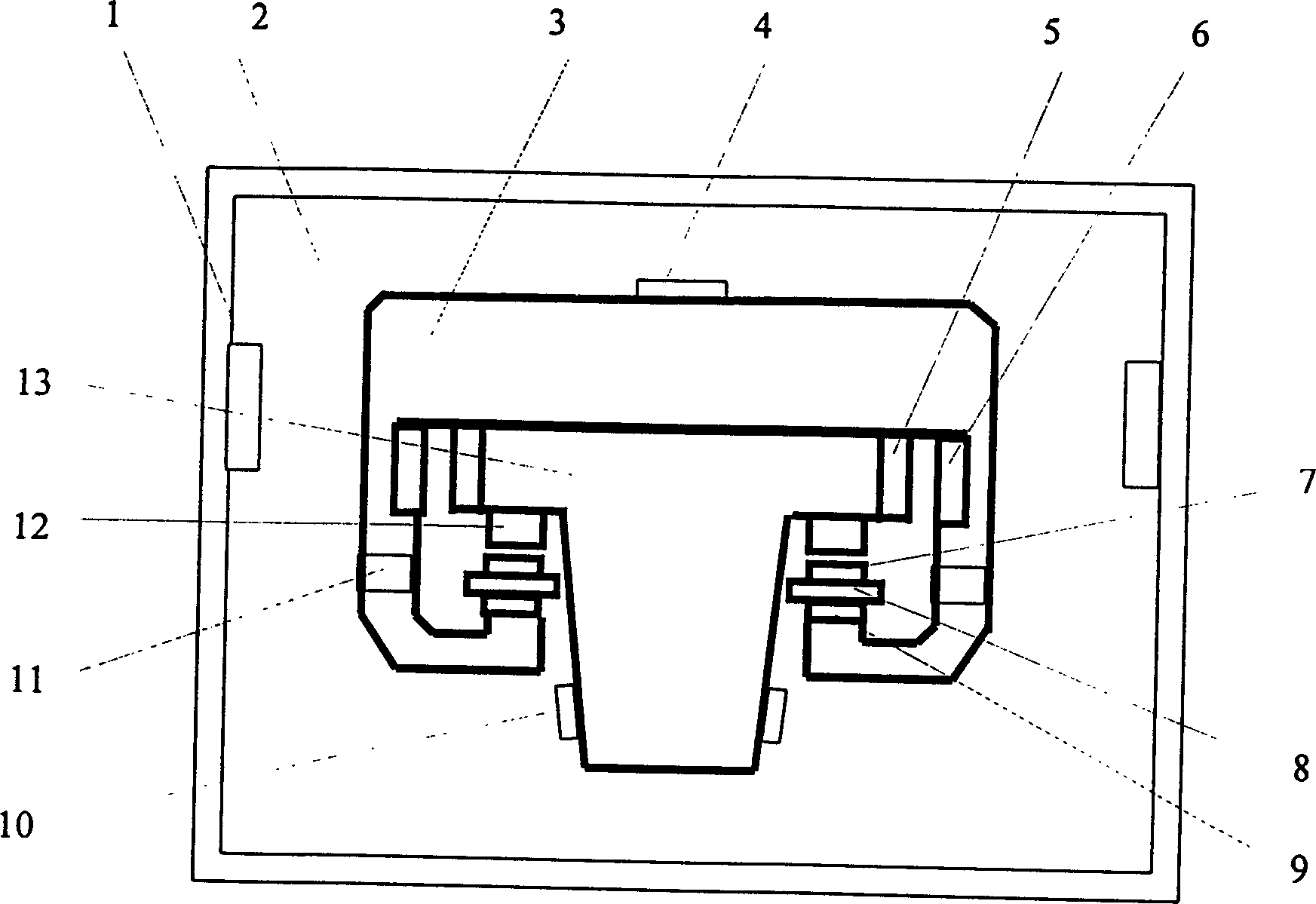

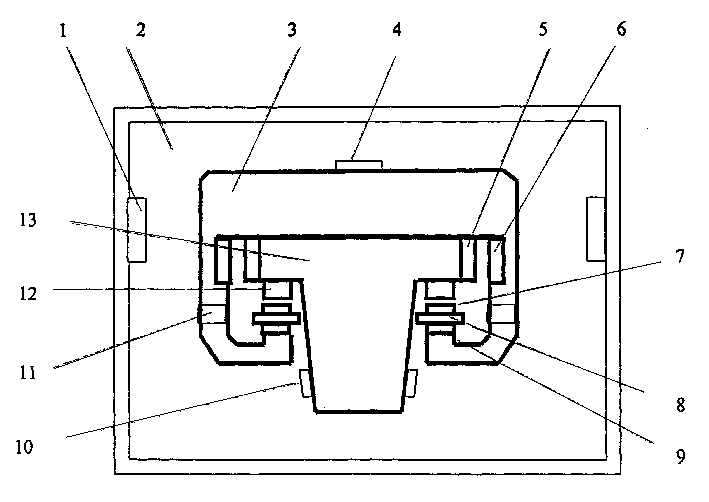

[0012] The constant conduction semi-suction floating maglev drive system used for ultra-precision machining has a constant temperature chamber 2, which is controlled by a cold and hot drive 1, and a rail guide 13 is provided in the constant temperature chamber, and drive windings 5 are provided on both sides of the rail guide 13, The lower end is provided with a suspension magnetic steel 12, a driving device 3 is provided on the guide rail, guiding and driving magnetic steel 6 corresponding to the track drive winding are provided on both inner sides of the driving device, and a suspension magnetic steel 6 is provided at the lower end of the driving device and the lower end of the guide rail. The permanent magnet 7, excitation coil 8, and pole core 9 corresponding to the steel are also provided with force sensors 11 on both sides of the driving device, a temperature sensor 4 is provided at the upper end, and a temperature sensor 10 is provided at the lower end of the guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com