Method and apparatus for directly synthesizing auro-potassium cyanide by controlling electric potential

A technology of potassium aurous cyanide and potassium cyanide, which is applied in the field of actual production equipment and direct synthesis of potassium aurous cyanide with improved control potential, which can solve problems affecting product quality, inability to use industrialized production, and large loss of raw materials. , to achieve the effect of eliminating the dead angle of poor mixing, stable product quality and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

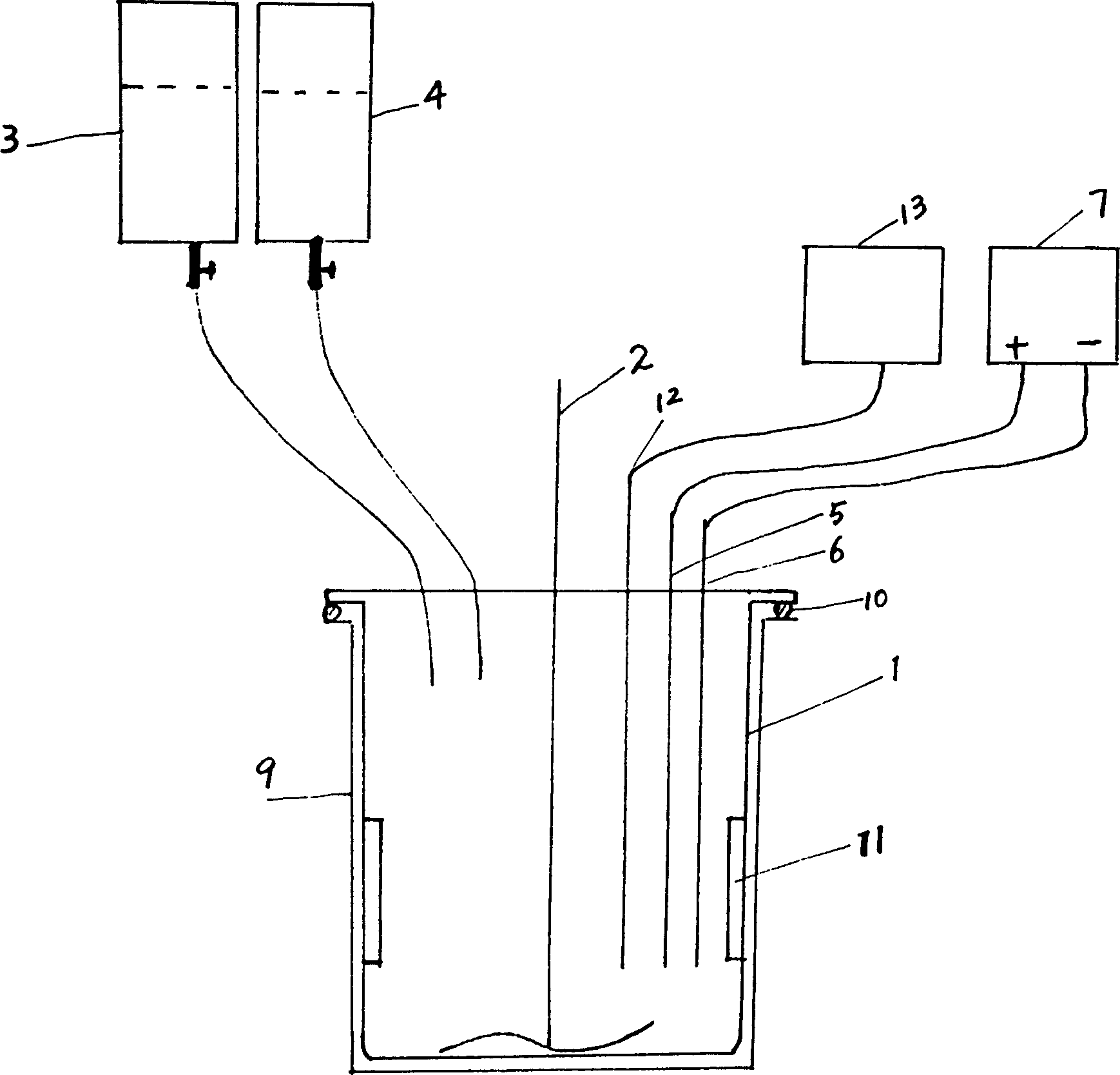

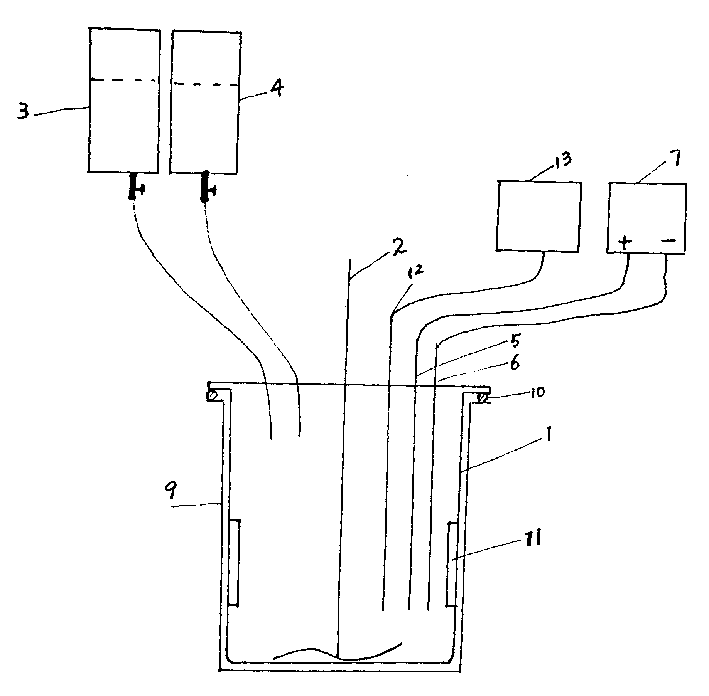

[0040] The specific operation steps of direct synthesis potassium aurous cyanide process method of control potential are as follows:

[0041] First, weigh 2kg of gold powder and 4.5l of hot water at 60-80°C according to the weight / volume ratio, add them into the reaction vessel, and stir thoroughly. Adjust the rotation speed of the stirrer 2 to suspend all the gold powder in the reaction vessel 1, and keep the rotating gold-containing solution relatively stable without splashing.

[0042] Under stirring conditions, through the potassium cyanide solution reservoir 3 and the hydrogen peroxide solution reservoir 4 with the control valve, gradually add the potassium cyanide solution with a concentration of 400g / l in the reaction vessel, and the addition speed is 120ml / min , add a hydrogen peroxide solution with a concentration of 30%, and the addition speed is 20ml / min, adjust the addition speed according to the display value of the potentiometer 7 and the temperature display inst...

Embodiment approach 2

[0044] The specific operation steps of direct synthesis potassium aurous cyanide process method of control potential are as follows:

[0045] Put 2kg of gold powder and 4.5l of hot water at 60-80°C into the reaction vessel and stir thoroughly. Suspend all the gold powder in the reaction vessel 1, and keep the rotating gold-containing solution relatively stable without splashing.

[0046] Under stirring conditions, through the potassium cyanide solution reservoir 3 and the hydrogen peroxide solution reservoir 4 with the control valve, gradually add the potassium cyanide solution with a concentration of 400g / l in the reaction vessel, and the addition speed is 180ml / min , adding concentration is the hydrogen peroxide solution of 30%, and adding rate is 30ml / min, adjusts its adding rate according to the display value of potentiometer 7 and temperature display instrument 13: adjusting method is the same as embodiment one, treats that potassium cyanide solution has been added After...

Embodiment approach 3

[0048] The specific operation steps of direct synthesis potassium aurous cyanide process method of control potential are as follows:

[0049] Put 2kg of gold powder and 4.5l of hot water at 60-80°C into the reaction vessel and stir thoroughly. Suspend all the gold powder in the reaction vessel 1, and keep the rotating gold-containing solution relatively stable without splashing.

[0050] Under stirring conditions, through the potassium cyanide solution reservoir 3 and the hydrogen peroxide solution reservoir 4 with the control valve, gradually add the potassium cyanide solution with a concentration of 400g / l in the reaction vessel, and the addition speed is 120ml / min , adding a hydrogen peroxide solution with a concentration of 30%, the adding speed is 20ml / min, adjust the adding speed according to the display value of the potentiometer 7 and the temperature display instrument 13: when the gold electrode potential value is lower than -530mV, add cyanide The potassium cyanide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com