Helical compressor and method of assembling the same

A technology of screw type and compressor, which is applied in the direction of rotary piston machinery, rotary piston pump, electromechanical device, etc., can solve the problems such as the long time spent in assembling the compressor, achieve convenient assembly process, reduce size, and improve reliability The effect of sex and mass productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

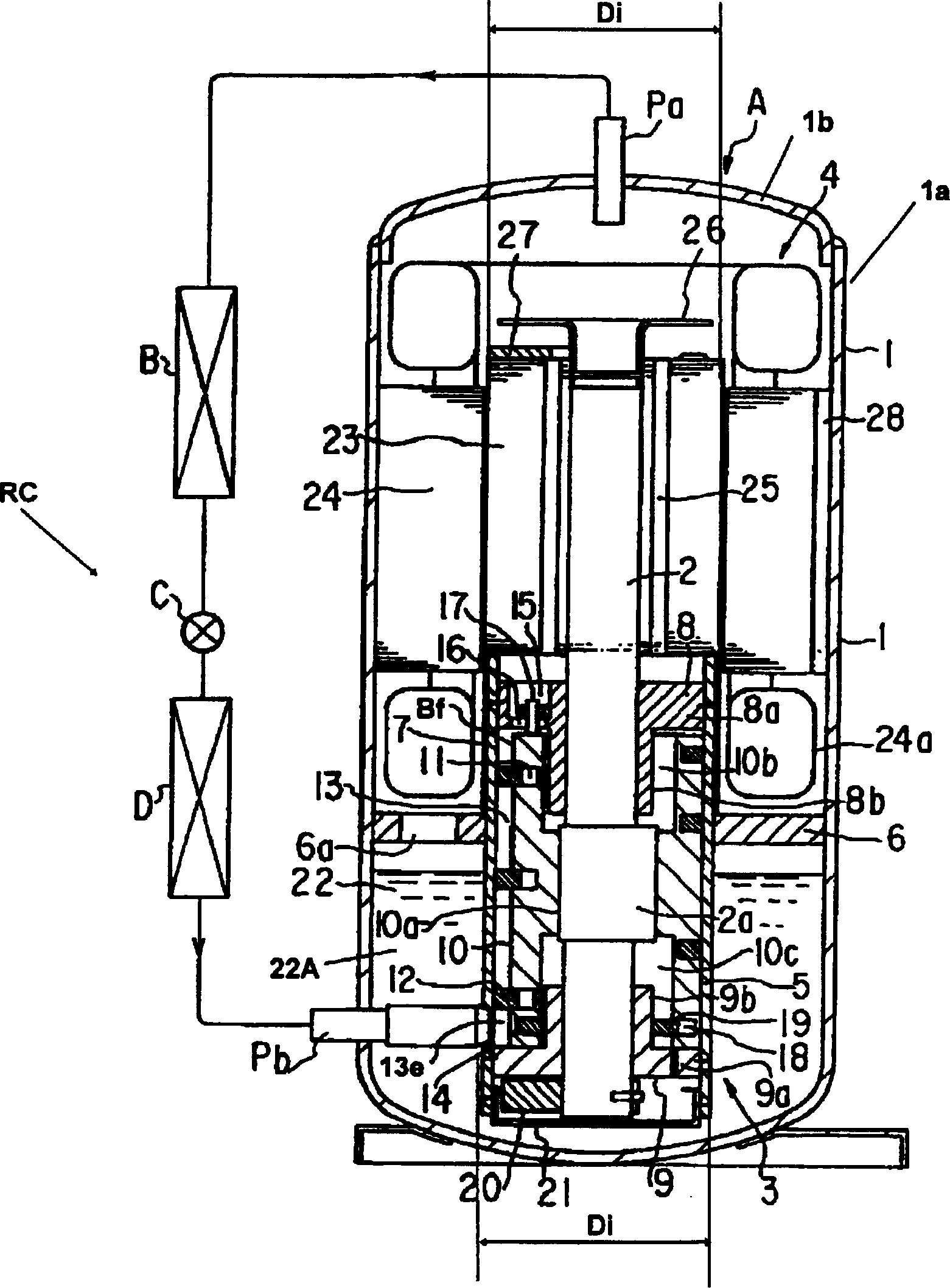

[0048] The following combination figure 1 A first embodiment of the present invention will be described.

[0049] Such as figure 1 As shown, a screw compressor A can establish a refrigeration cycle RC of an air conditioner, a refrigerator, a freezer or other similar equipment. The screw compressor A has a discharge side refrigerant pipe Pa connected to, for example, the upper surface of its upper portion in this embodiment, and has a suction side refrigerant pipe Pb connected to, for example, its side surface. From the outlet side refrigerant pipe Pa to the suction side refrigerant pipe Pb, a condenser B, an expansion valve C acting together to a pressure reducing mechanism, and an evaporator D are sequentially connected and communicated, thereby establishing a refrigeration cycle RC .

[0050] The aforementioned screw compressor A is arranged such that its longitudinal direction, such as its central axis, is perpendicular to the horizontal plane, so it is called a vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com