Maze biological carrier separator for biological fluidizing reactor

A biological carrier and biological fluidization technology, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of unsatisfactory effect in the sedimentation area of the separator, so as to improve the separation effect and increase the speed , the effect of reducing the loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

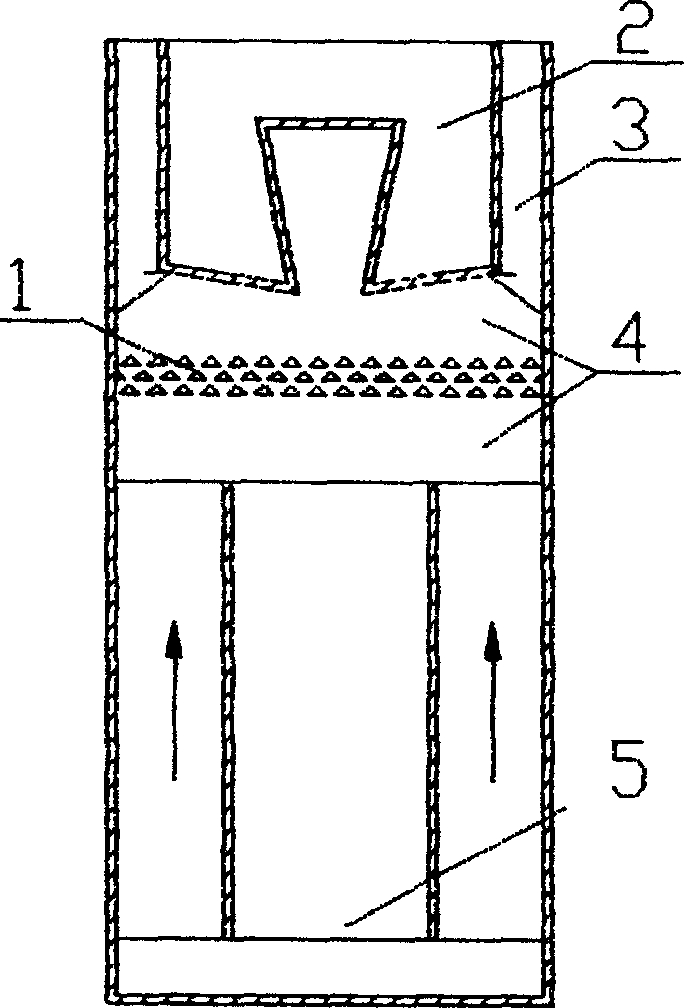

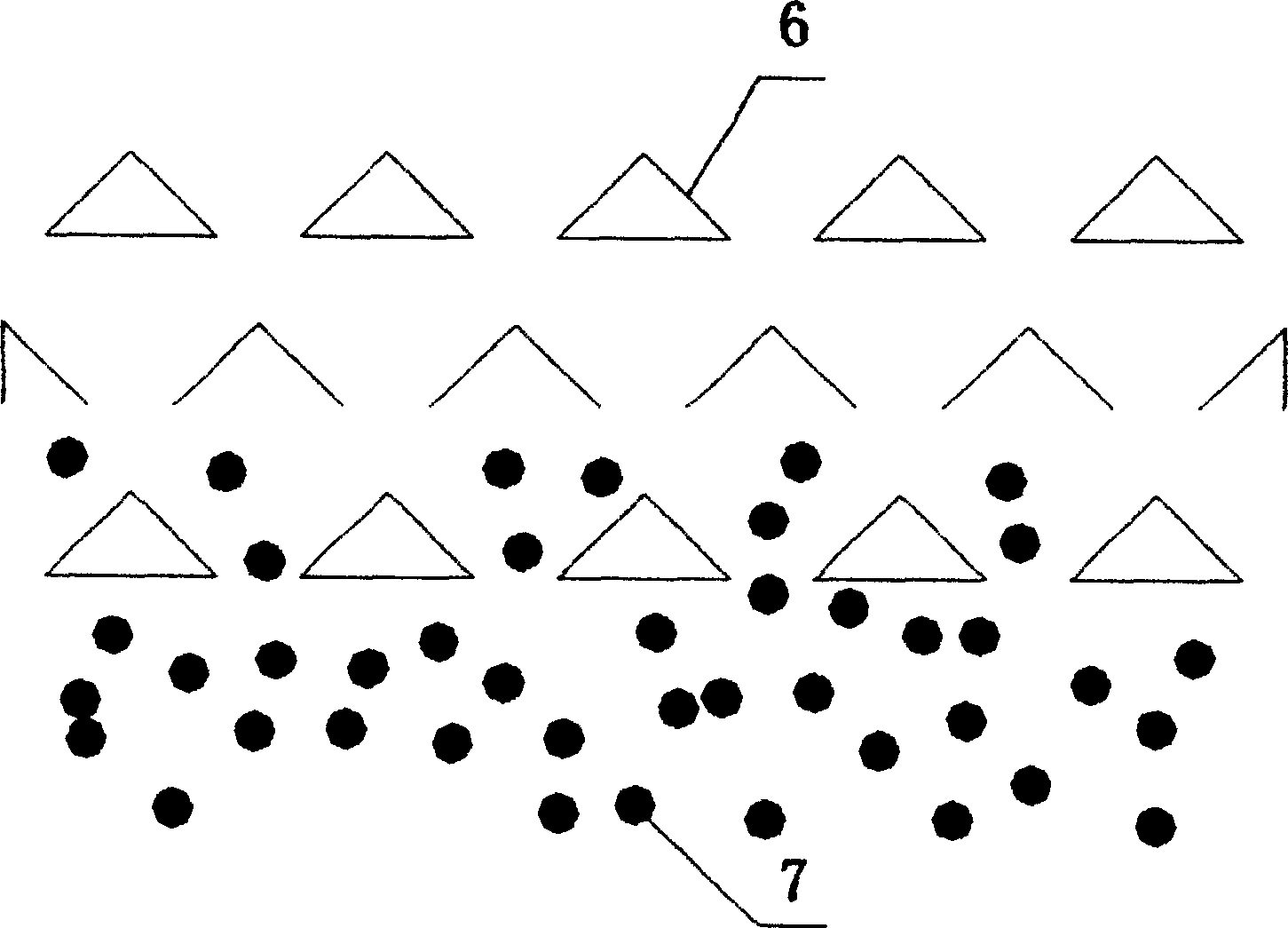

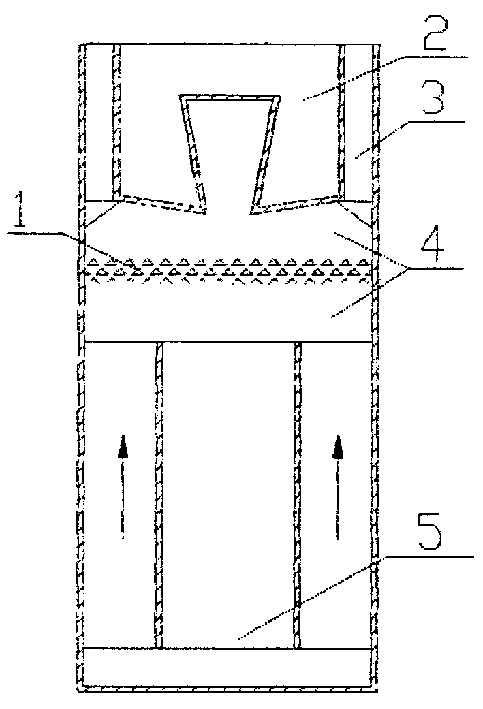

[0010] The present invention is a kind of labyrinth biological carrier separator used for biological fluidized reactor used in airlift reactor, water and gas of general airlift reactor all enter from the bottom of reactor; The biological carrier separator 1 is composed of three layers of interlaced triangular reflective cones 6, installed in the middle of the reactor, the upper part of the reactor is an air flotation separator 2, and the surrounding area of the air flotation separator 2 is a high-efficiency separation zone 3, a labyrinth carrier separator The upper and lower sides of 1 are the reactor buffer zone 4, and the lower part is the fluidized reaction zone 5. The periphery of this zone is an aerobic zone, and the middle part is an anoxic zone. The reflective cone 6 restricts the passage of the fluidized carrier 7, which is used to limit the biological carrier 7 in the suspended fluidized state to the aerobic reaction zone, preventing the biological carrier and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com