Weft stop motion

A self-stop device and weft breaking technology, applied in textile, textile and papermaking, looms and other directions, can solve the problems of machine surface weft breakage, weft missing defective cloth, increase production time and production cost, etc. Density reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

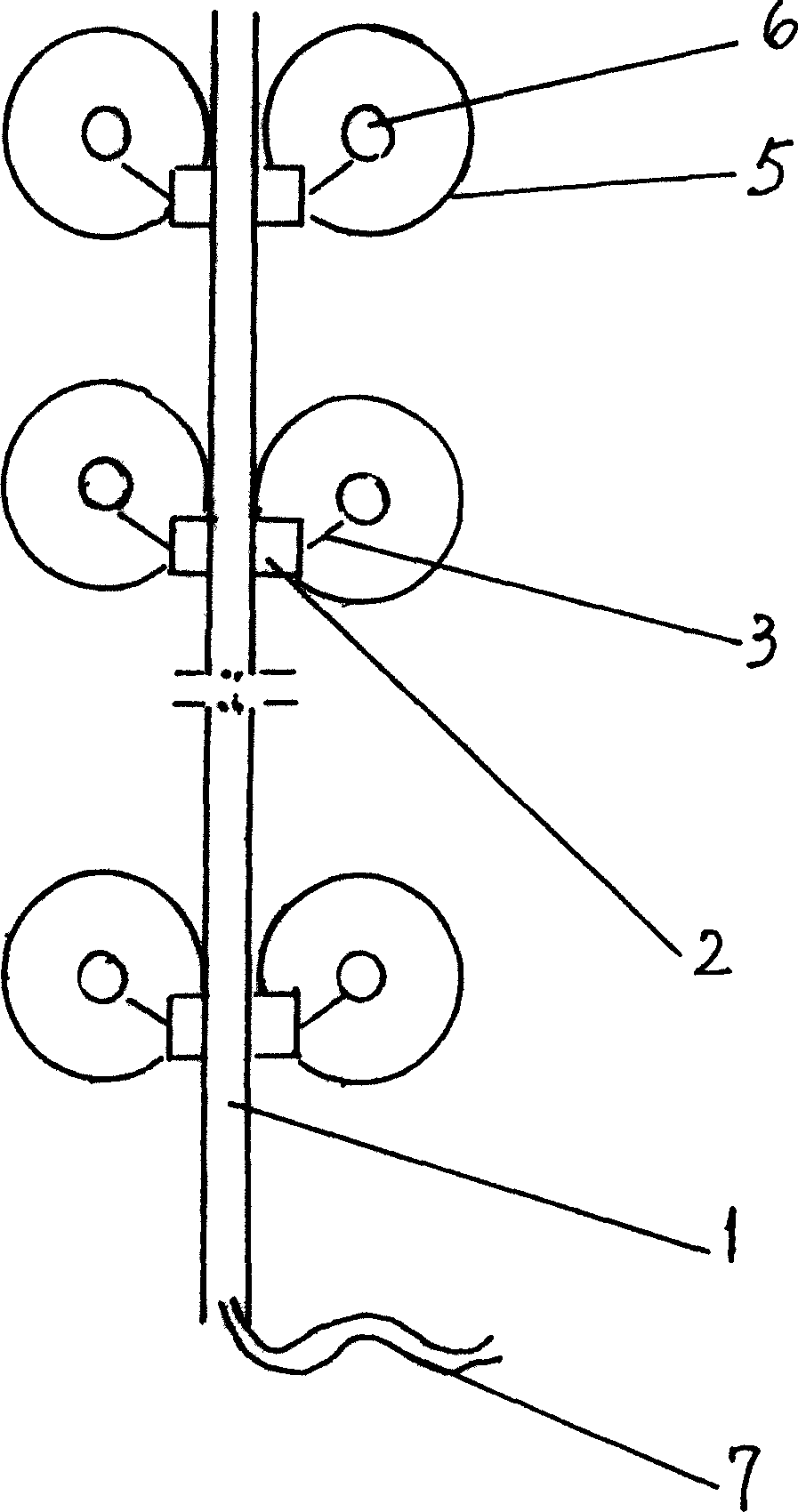

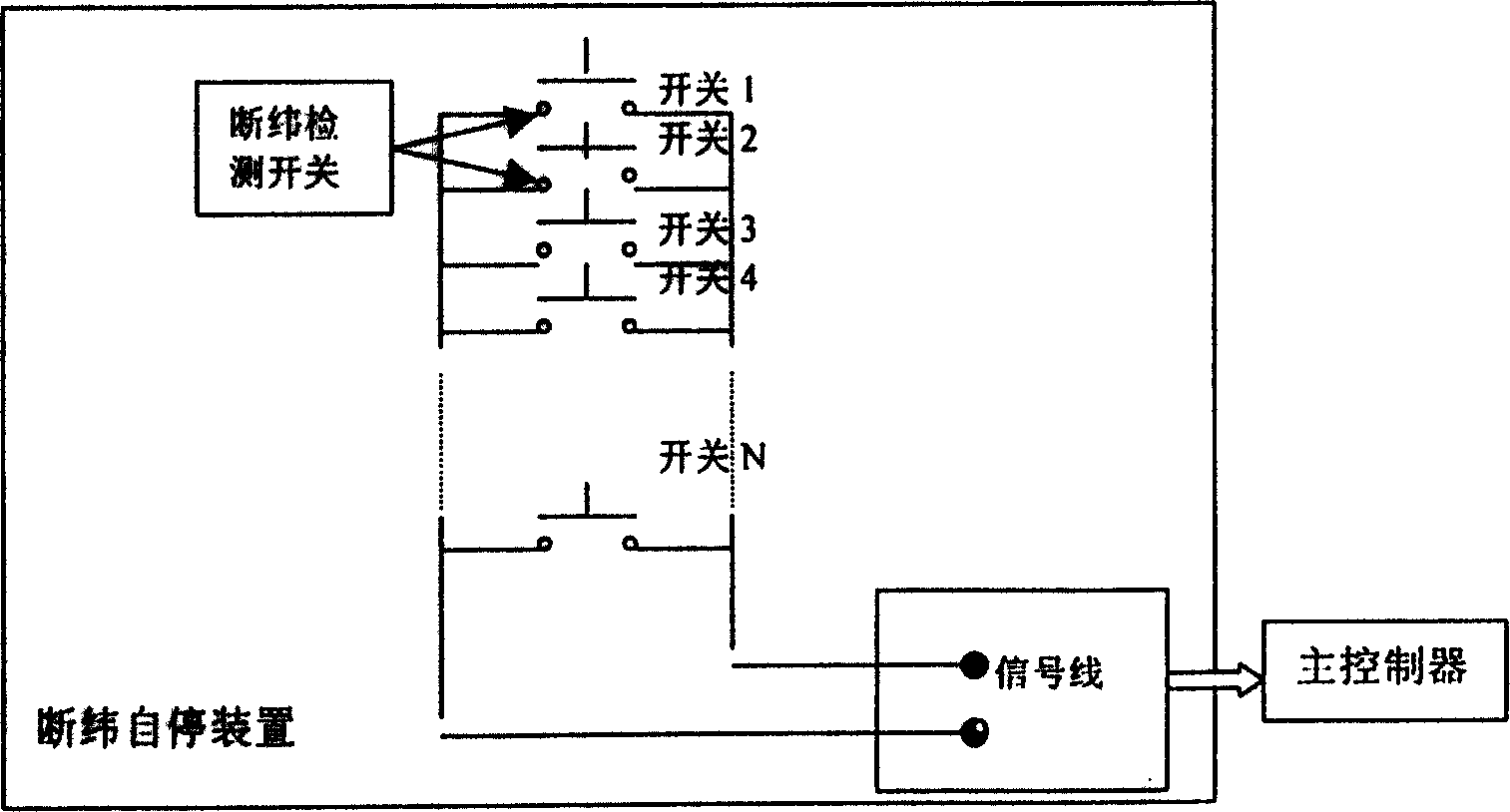

[0013] The weft breaking self-stop device is a device that detects the yarn breaking signal and transmits the yarn breaking signal to loom to stop the loom; this device can also be used to weave weaving varieties that cannot have knots by detecting a single weft yarn. machine, stop the loom, and start the machine after disposing of the weft yarn in the knotted part.

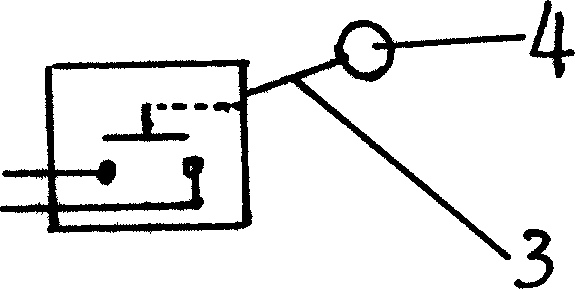

[0014] The weft-continuing self-stop device on each loom can be equipped with multiple weft-broken detection switches. When there are unused weft-broken detection switches, they can be placed in idle gear without affecting the detection of other weft-broken switches. Weft breakage detection switch can adopt contact switch, photoelectric sensor switch or other types of yarn sensor switch, when any weft breakage detection switch detects the signal of weft yarn breakage, it will send the detection master number to the main controller of the loom , the main controller processes the signal and sends a stop command to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com