Absorbent article with open pore film

An absorbent and porous film technology, applied in the direction of absorbent pads, layered products, synthetic resin layered products, etc., can solve the problems of difficult to form stable shape holes, strength reduction, stable forming of easy and difficult holes, etc., to achieve inhibition Effect of reducing stickiness and irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

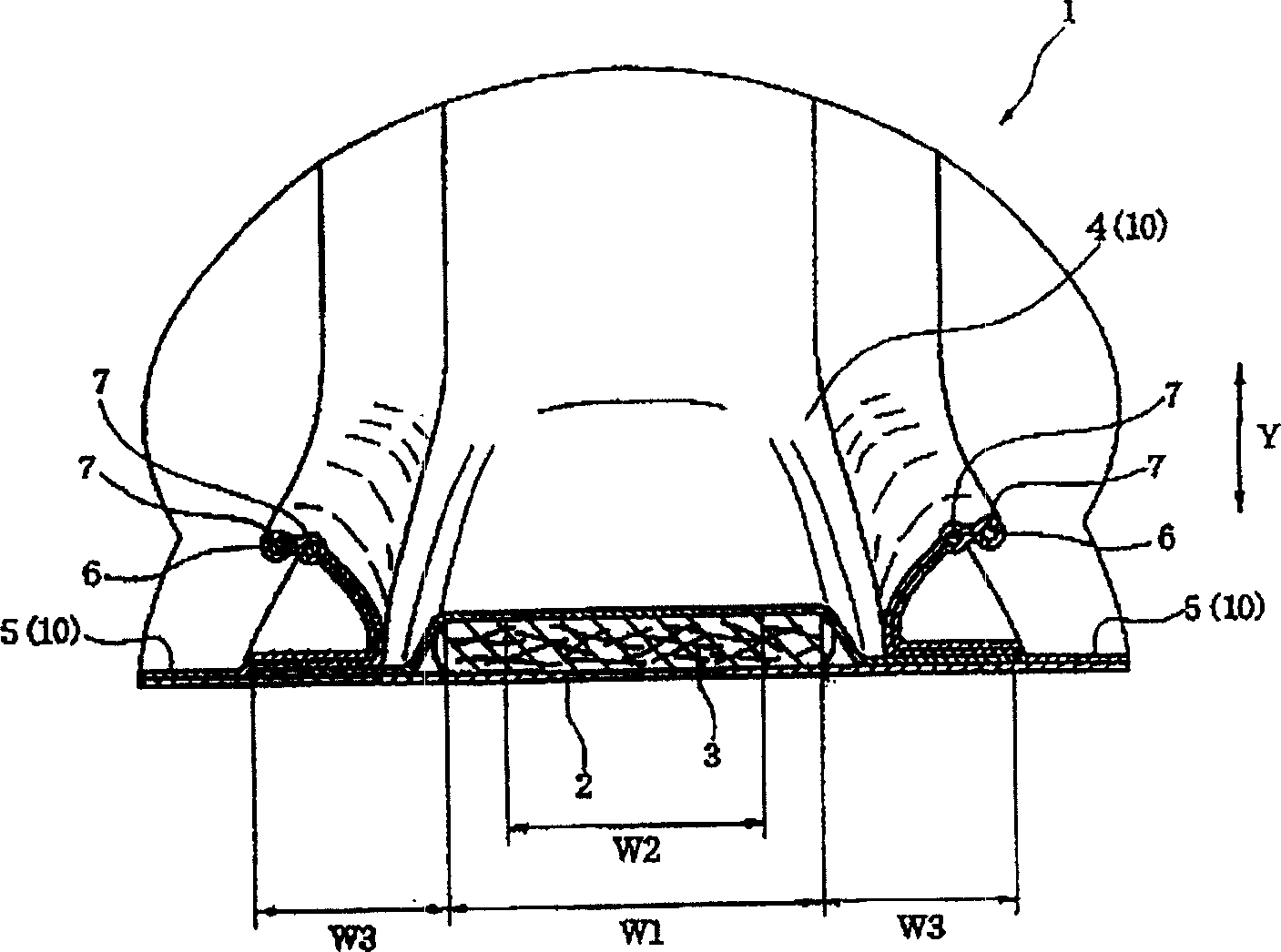

[0046] Stretch the following mixed resin through a melt extruder and a die to obtain a weight per unit area of 25g / m 2 film of a mixed resin in which, by mass, the block copolymer of polyester is 40% and the density is 0.915 g / cm 3 The LLDPE is 60%. The vapor permeability of the film is 2214g / m 2 / 24 hours.

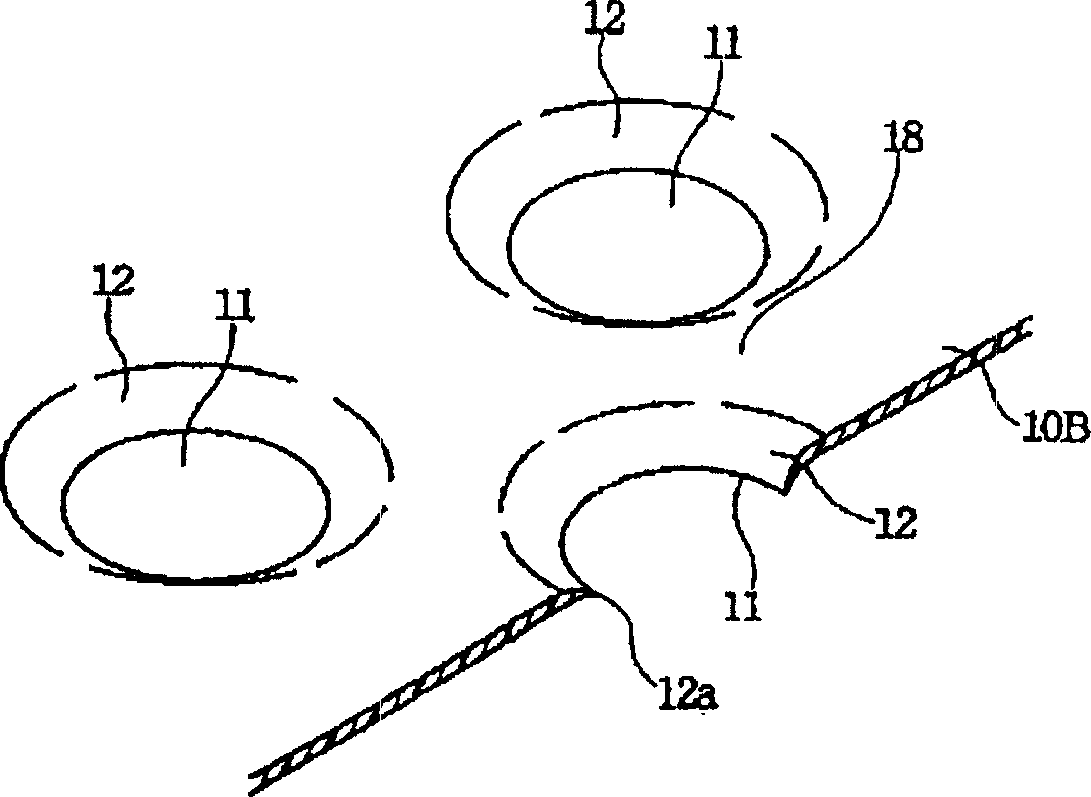

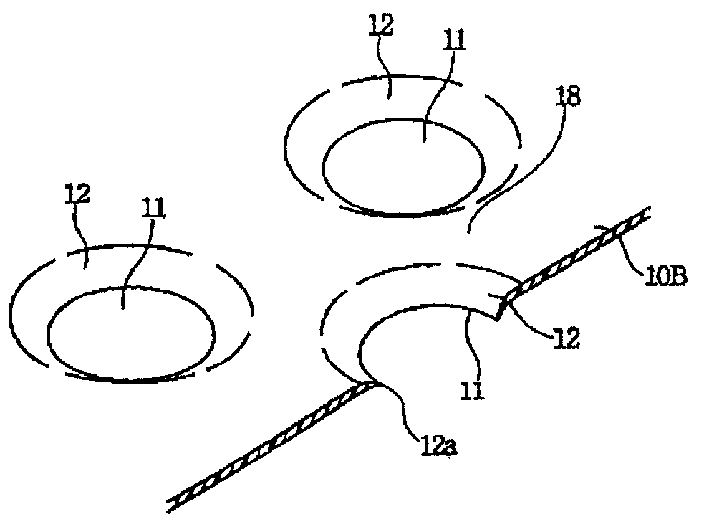

[0047] The above-mentioned film was transferred to a sieve drum, preheated with hot air at 350°C, and then sucked by suction pressure to obtain the following open-pored film in which the area ratio of the pores was 61%. The height is 0.42mm, and its shape is the same as figure 2 Same as shown.

[0048] When the apertured film obtained above was stretched at a speed of 100 mm / min at a width of 1 inch (2.54 cm), the breaking strength in the machine direction (MD) was 8.7 N, and the breaking strength in the transverse direction (MD) was 3.1 N. In addition, it is known that the compressibility is 33% when a pressure of 4900 Pa is applied by a KES air-sealing tester, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com