Oxygen-enriching heat-accumulating air preheating and flue gas recirculating apparatus

A technology of flue gas recirculation and oxygen-enriched air, applied in waste heat treatment, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problem of reduction of combustion products, increase of combustion temperature, oxygen-enriched combustion or high-temperature heat storage combustion transformation Problems such as the decline in investment economy, to achieve the effect of improving investment economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

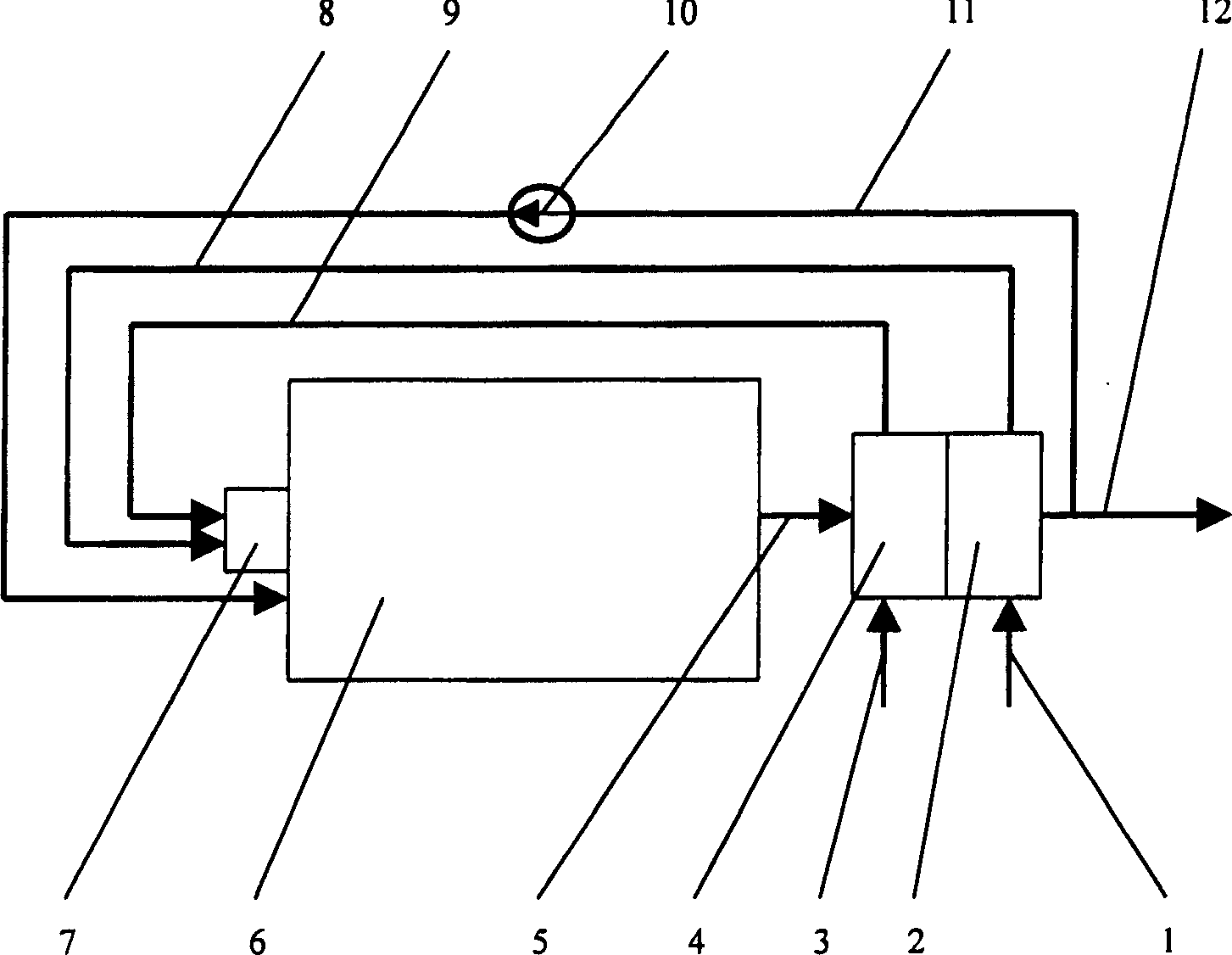

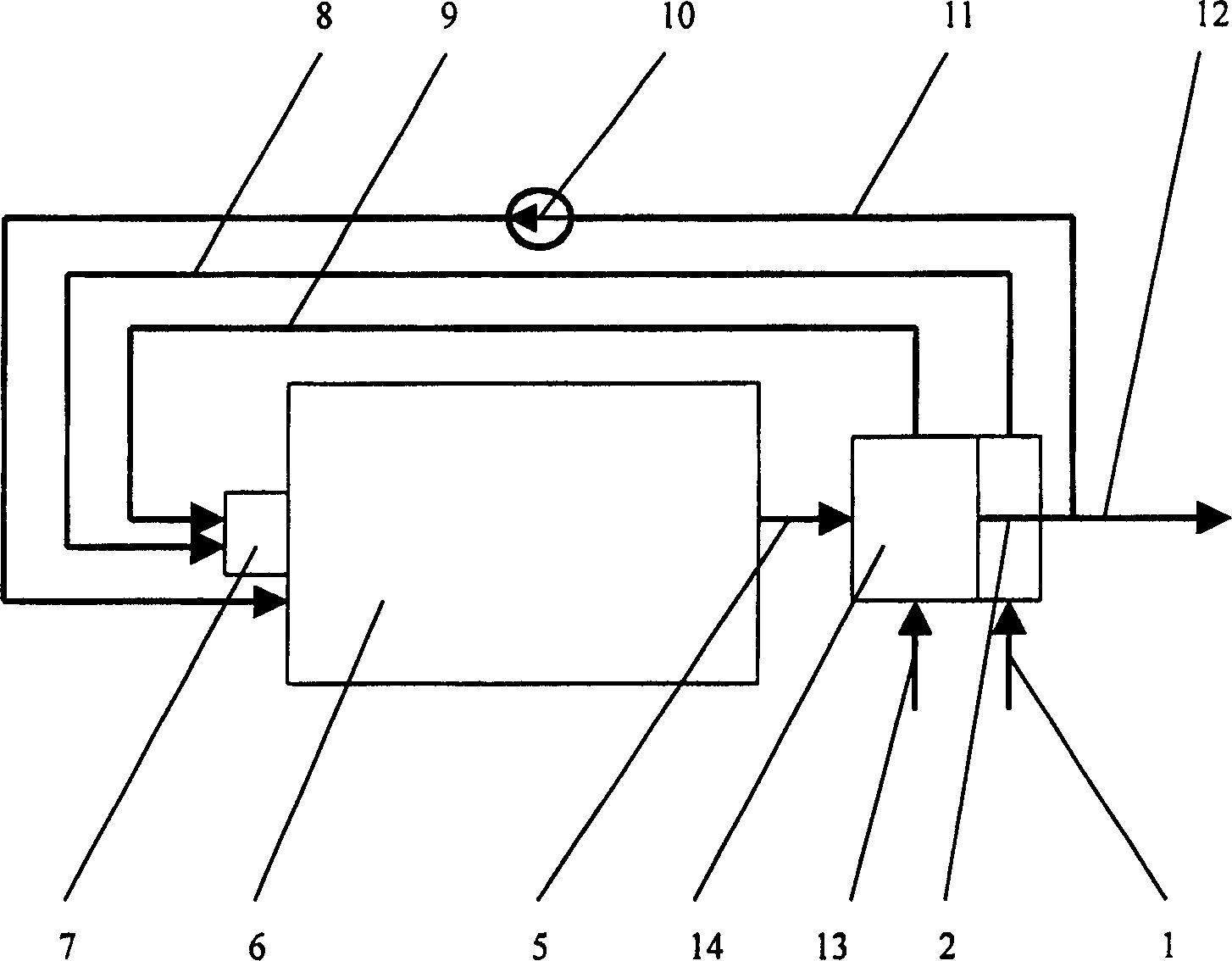

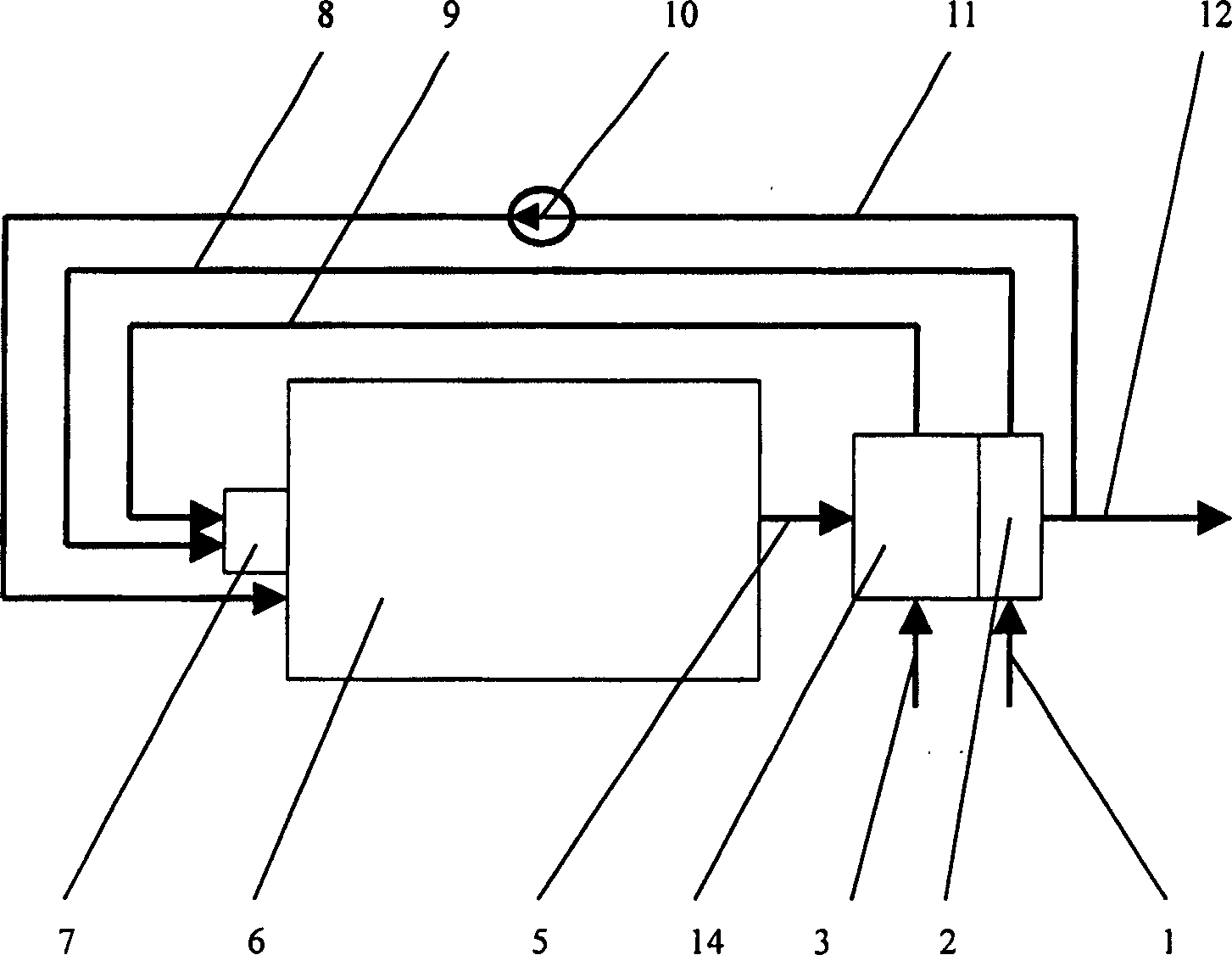

[0031] according to figure 1 The schematic diagram of the combined process of the oxygen-enriched combustion system and the flue gas recirculation system shows that the combined process of the two is that the oxygen-enriched air passes through the oxygen-enriched air inlet pipe 3 in the oxygen-enriched air preheater and between the furnace and the air preheater. The flue gas discharged from the flue 5 in between is subjected to heat exchange in the oxygen-enriched air preheater 4, wherein the oxygen-enriched air absorbs the heat of the flue gas and is heated, and the flue gas at the outlet of the oxygen-enriched air preheater is cooled; the gas passes through the gas inlet pipe 1 In the gas preheater, the flue gas from the outlet of the oxygen-enriched air preheater performs heat exchange in the gas preheater 2, in which the gas absorbs the heat of the flue gas and is heated, and the flue gas at the outlet of the gas preheater cools down and enters the flue gas Gas discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com