Method for producing nano diamond particles purified by cerium salt

A nano-diamond and nano-carbon particle technology is applied in the field of cerium salt purification of nano-diamond particles, which can solve the problem of high investment cost, and achieve the effect of broad application prospects and low pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Add 100 mg of carbon nano-particles after vacuum constant weight into 10 ml of 100 g / ml ammonium cerium sulfate solution, absorb at 30° C. for 24 hours with constant temperature oscillation, and centrifuge to separate nano-diamonds. The nanodiamonds were washed 3 times with 5% (V / V) sulfuric acid solution, and then washed with deionized water until pH≈7. Vacuum drying at 100° C. for 24 hours to obtain nanodiamond particles.

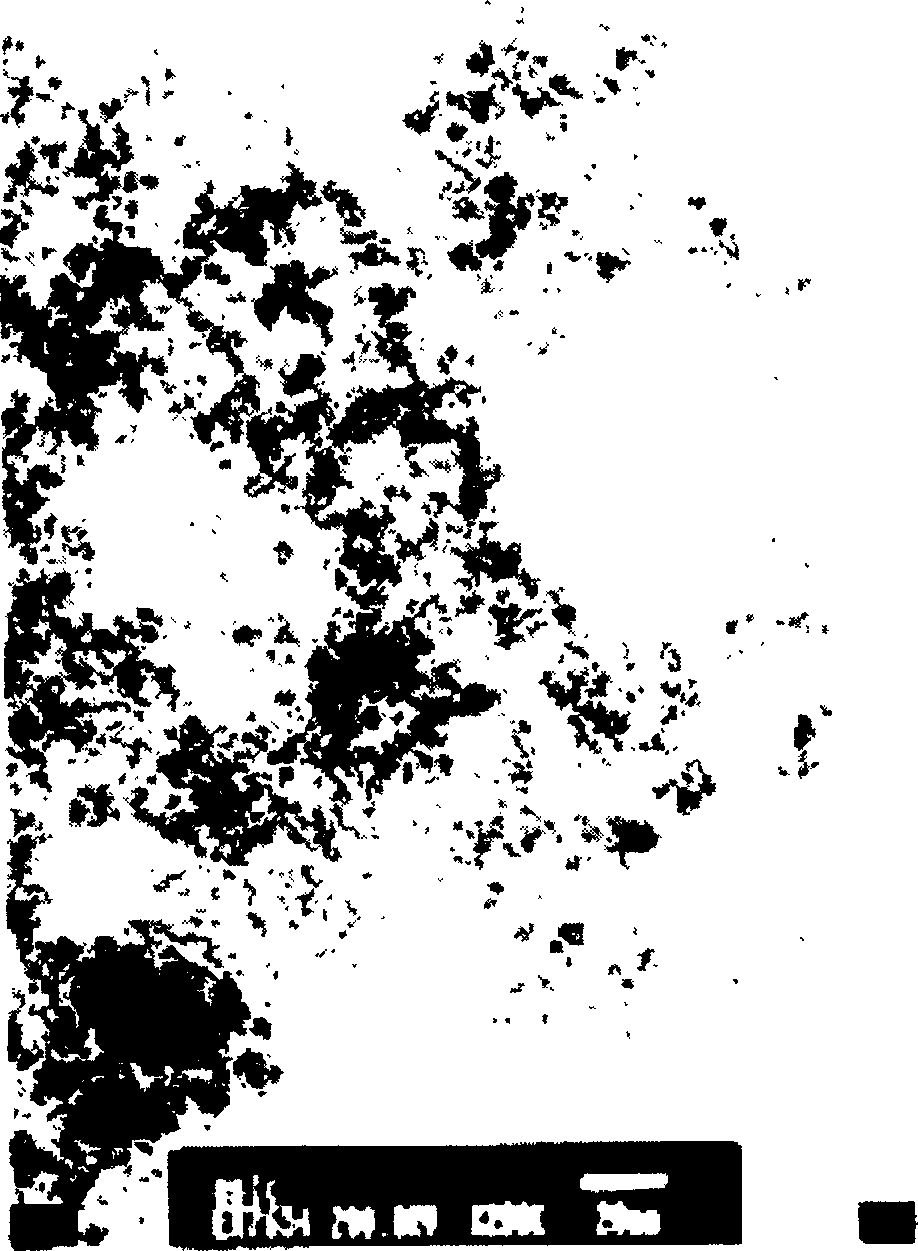

[0015] The particle diameter of the nano-diamond particles prepared by the above-mentioned method adopts transmission electron microscope to measure, and its result is as follows: figure 1 shown. figure 1 The results show that the particle size of nano-diamond particles is 4-6nm.

Embodiment 2

[0016] Example 2: Add 100 mg of carbon nano-particles after vacuum constant weight into 100 ml of 10 g / ml ammonium cerium nitrate solution, absorb at 50° C. for 24 hours with constant temperature oscillation, and centrifuge to separate nano-diamonds. The nano-diamond was washed 3 times with 3% (V / V) sulfuric acid solution, and then washed with deionization to pH ≈ 7. Vacuum drying at 120°C for 12 hours to obtain nanodiamond particles.

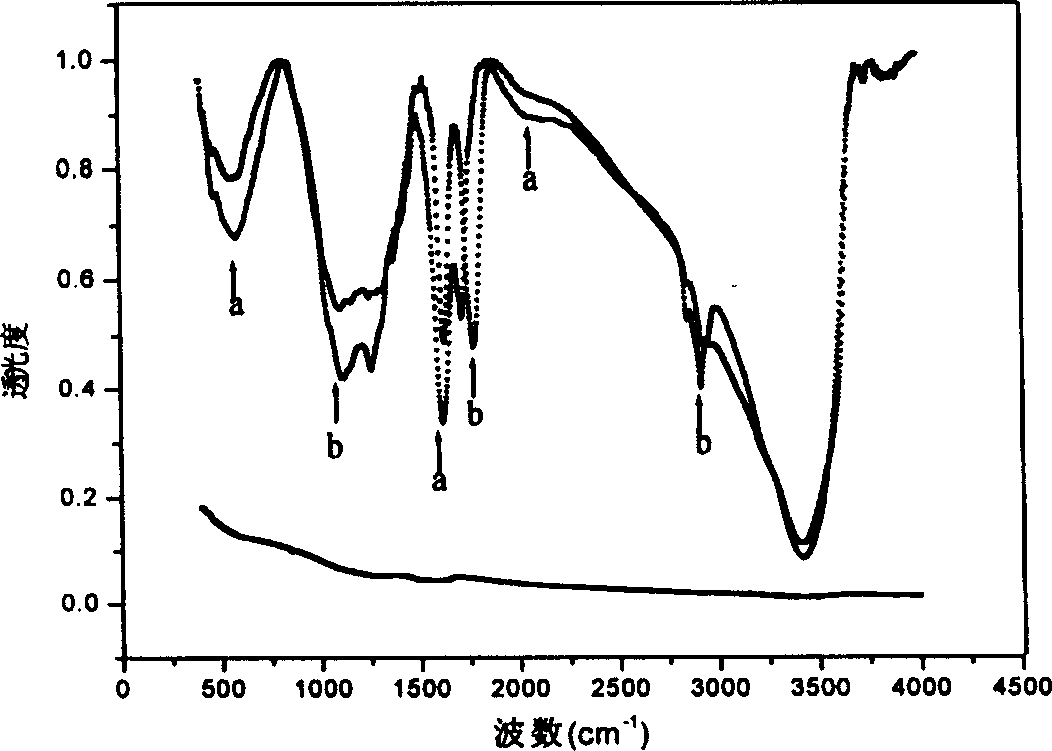

[0017] The functional groups on the surface of the nano-diamond particles prepared by the above method are measured by infrared spectroscopy, and the results are as follows: figure 2 shown. figure 2 The results showed that the appearance of carbon nano-particles was black, and the result of infrared spectrum was broad-spectrum absorption. The infrared spectrum of nano-diamond particles purified by nitric acid is slightly different from that of nano-diamond particles purified by cerium salt.

Embodiment 3

[0018] Example 3: Add 100 mg of carbon nano-particles after vacuum constant weight into 20 ml of 40 g / ml ammonium cerium sulfate solution, absorb at 70° C. for 24 hours with constant temperature oscillation, and centrifuge to separate nano-diamonds. The nano-diamonds were washed 5 times with 1% (V / V) sulfuric acid solution, and then deionized to pH ≈ 7. Vacuum drying at 100° C. for 24 hours to obtain nanodiamond particles.

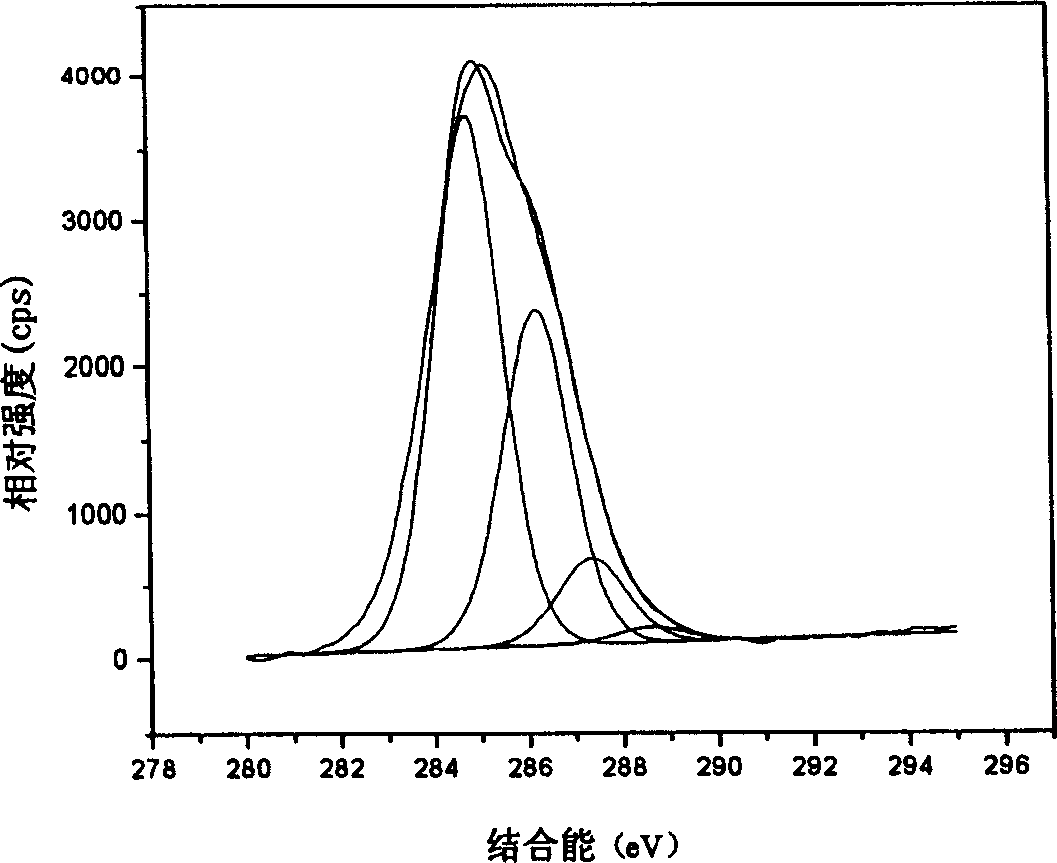

[0019] The functional group on the surface of the nano-diamond particles prepared by the above method adopts X-ray photoelectron energy spectrometer, and the O 1S and C 1S Automatically fit and split peaks to obtain nano-carbon particles (see image 3 , Figure 4 ), nitric acid purification of nano-diamond particles (see Figure 5 , Figure 6 ) and cerium salt purified nano-diamond particles (see Figure 7 , Figure 8 ) of C 1S peak spectrum and O 1S Peak spectrum, such as Figure 3 ~ Figure 8 shown. The XPS analysis results of cerium salt purif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com