Hexachlorodisilane purification device and method

A technology of hexachlorodisilane and silane, which is applied in the field of hexachlorodisilane purification, and can solve the problems that pentachlorodisilane cannot be separated cleanly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

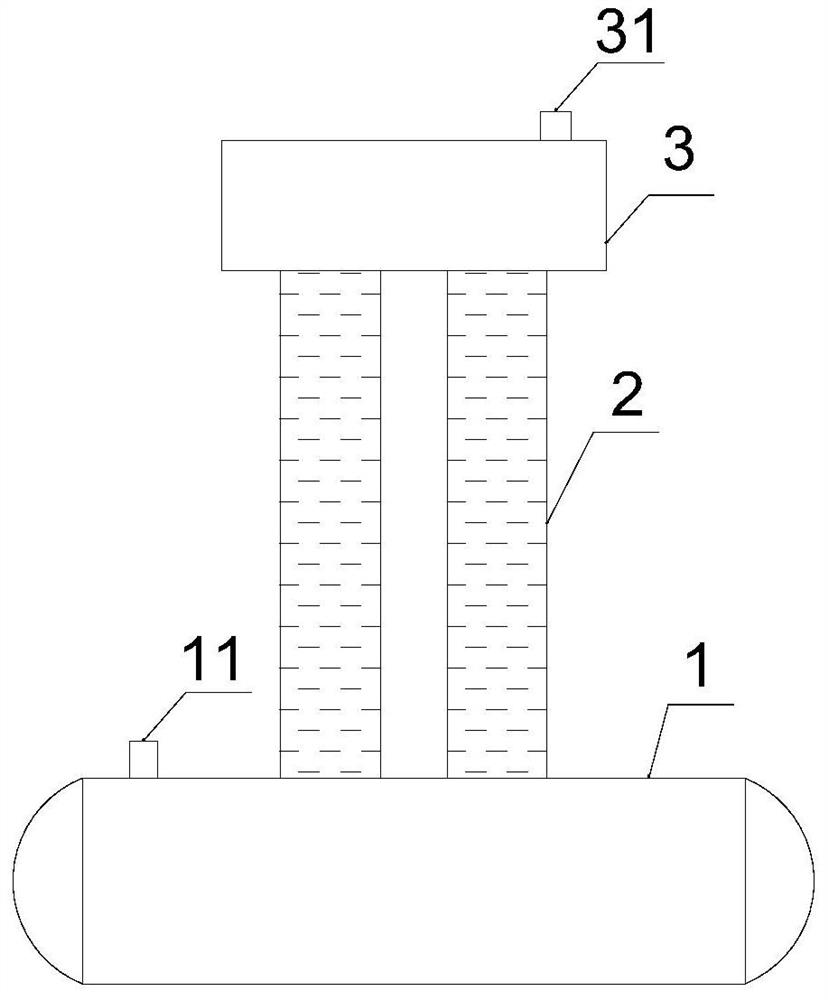

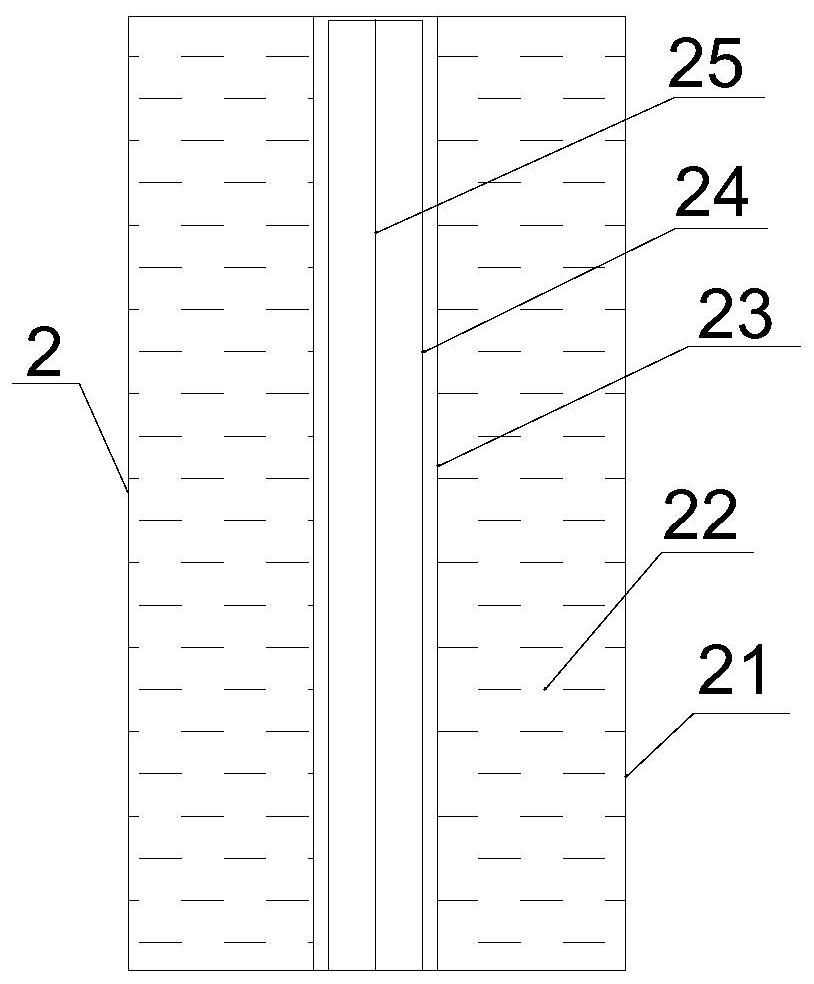

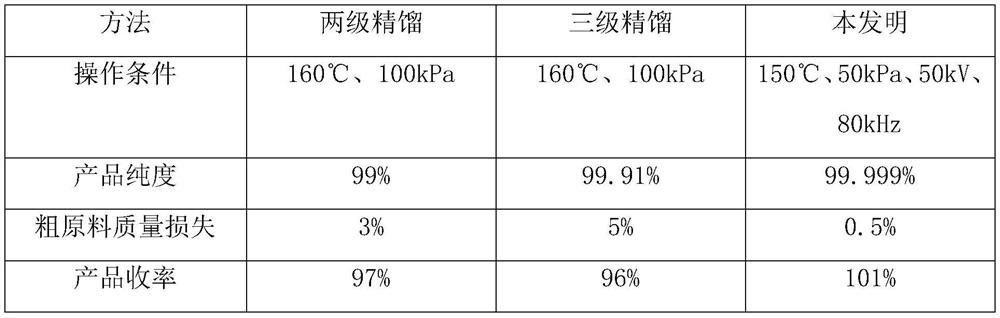

[0029] Such as figure 1 As shown, in Example 1, a hexachlorodisilane purification device, the purification device specifically includes a raw material tank 1, a reactor 2 and a cooler 3 connected in sequence; the raw material tank 1 is provided with a raw material inlet 11, and the raw material tank 1 is provided with a heater (not shown in the figure); the reactor 2 is provided with an electrode, and the reactor 2 has a gas interface adapted to the chlorine gas inlet pipeline; the cooler 3 is provided with a collection port 31. Specifically, the raw material tank 1 , the reactor 2 and the cooler 3 are arranged from bottom to top, the raw material tank 1 communicates with the lower end of the reactor 2 , and the cooler 3 communicates with the upper end of the reactor 2 . The heater is used to heat the material, that is, to heat the hexachlorodisilane liquid containing pentachlorodisilane. As an embodiment, the heater is a plurality of heat pipes suspended on the top of the raw...

Embodiment 2

[0038] This embodiment has the same inventive concept as Example 1, and a method for purifying hexachlorodisilane is provided on the basis of Example 1. The method specifically includes the following steps:

[0039] S01: The hexachlorodisilane liquid containing pentachlorodisilane is transported to the raw material tank 1 and heated, and the hexachlorodisilane liquid containing pentachlorodisilane starts to gasify and enters the reactor 2; wherein, the heating temperature is 100- 300°C, preferably 200°C, a heating pipe can be installed on the top of the raw material tank 1 to heat the material.

[0040] S02: Pass chlorine gas into the reactor 2, and switch on the power supply of the electrodes in the reactor 2; wherein, the molar ratio of chlorine gas to pentachlorodisilane is 1:1-30:1.

[0041] S03: Extract low-boiling point hydrogen chloride and chlorine gas in the gas phase, and store high-purity hexachlorodisilane liquid in the raw material tank 1 after the reaction is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com