A kind of hexachlorodisilane purification device and method

A technology of hexachlorodisilane and purification method, which is applied in the field of hexachlorodisilane purification device containing pentachlorodisilane, can solve the problems such as inability to separate pentachlorodisilane cleanly, achieve improved purity, increase yield, and green purification method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

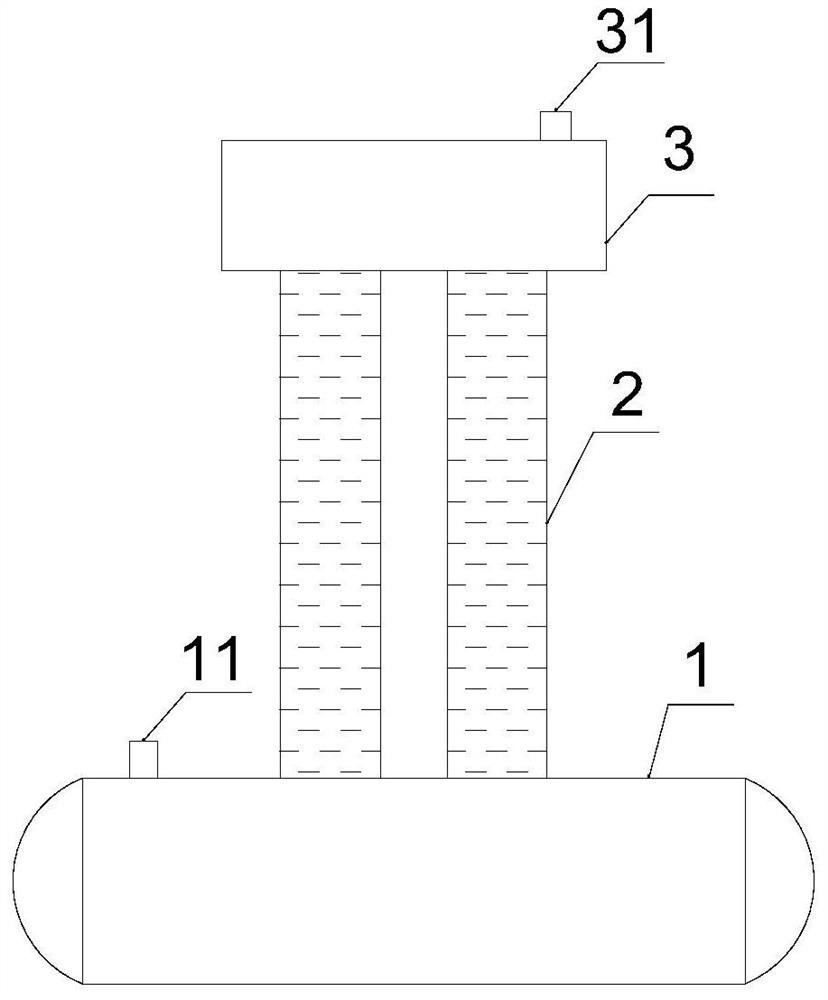

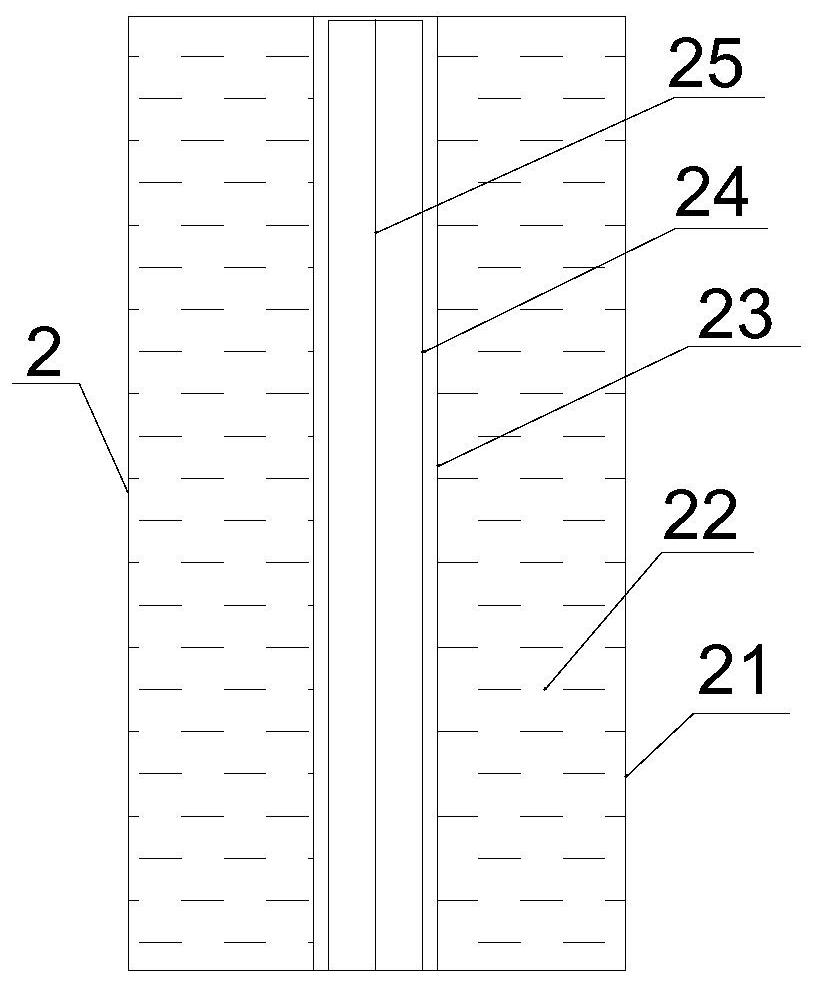

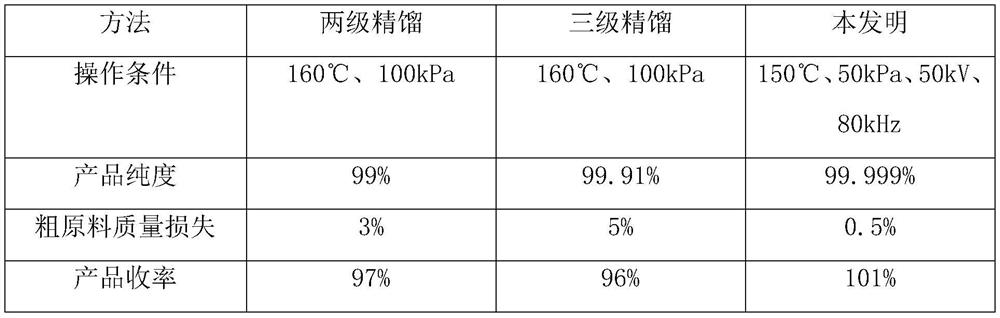

[0029] like figure 1 As shown, in Example 1, a hexachlorodisilane purification device, the purification device specifically includes a raw material tank 1, a reactor 2 and a cooler 3 that are communicated in sequence; the raw material tank 1 is provided with a raw material inlet 11, and the raw material tank 1 is provided with a heater (not shown in the figure); the reactor 2 is provided with an electrode, and the reactor 2 has a gas interface adapted to the chlorine inlet pipeline; the cooler 3 is provided with a collection port 31. Specifically, the raw material tank 1 , the reactor 2 and the cooler 3 are arranged from bottom to top, the raw material tank 1 is communicated with the lower end of the reactor 2 , and the cooler 3 is communicated with the upper end of the reactor 2 . The heater is used to heat the material, that is, to heat the hexachlorodisilane liquid containing pentachlorodisilane. As an embodiment, the heater is a number of heat pipes suspended on the top of...

Embodiment 2

[0038] This embodiment has the same inventive concept as Embodiment 1, and a method for purifying hexachlorodisilane is provided on the basis of Embodiment 1, and the method specifically includes the following steps:

[0039] S01: The hexachlorodisilane liquid containing pentachlorodisilane is transported to the raw material tank 1 and heated, and the hexachlorodisilane liquid containing pentachlorodisilane begins to vaporize and enters the reactor 2; wherein, the heating temperature is 100- At 300°C, preferably 200°C, a heating pipe can be arranged on the top of the raw material tank 1 to heat the material.

[0040] S02: Pass chlorine gas into the reactor 2, and turn on the power supply of the electrodes in the reactor 2; wherein, the molar ratio of chlorine gas to pentachlorodisilane is 1:1-30:1.

[0041] S03: extract low-boiling hydrogen chloride and chlorine in gas phase, and store high-purity hexachlorodisilane liquid in raw material tank 1 after the reaction is completed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com