Multi-phase loom with magnetic shuttle

A technology of looms and sheds, which is applied in the field of weft-opening flat multi-phase looms, can solve the problems of low efficiency of looms, achieve the effects of improved beating-up efficiency, low mechanical friction, and reduced weaving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

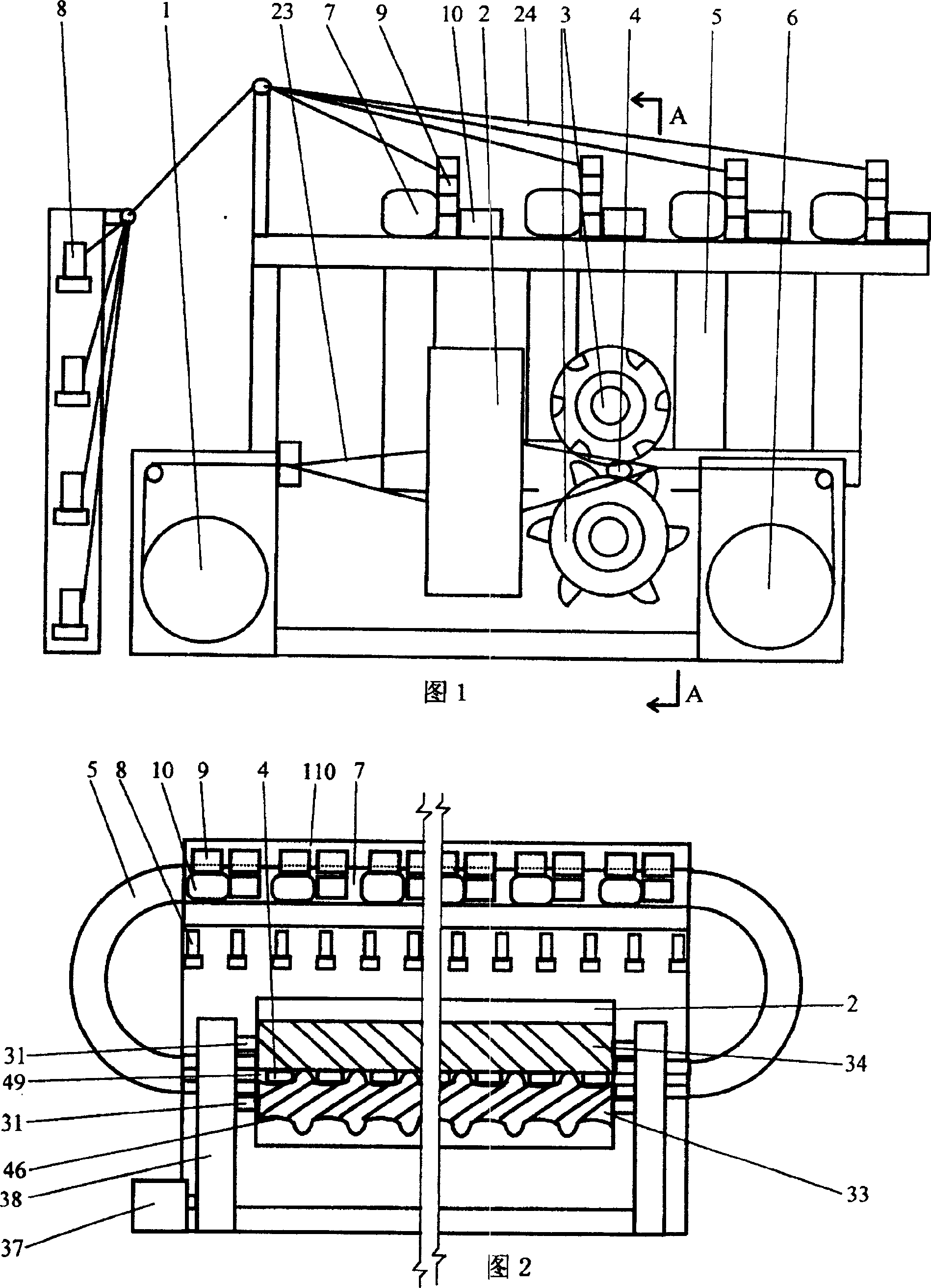

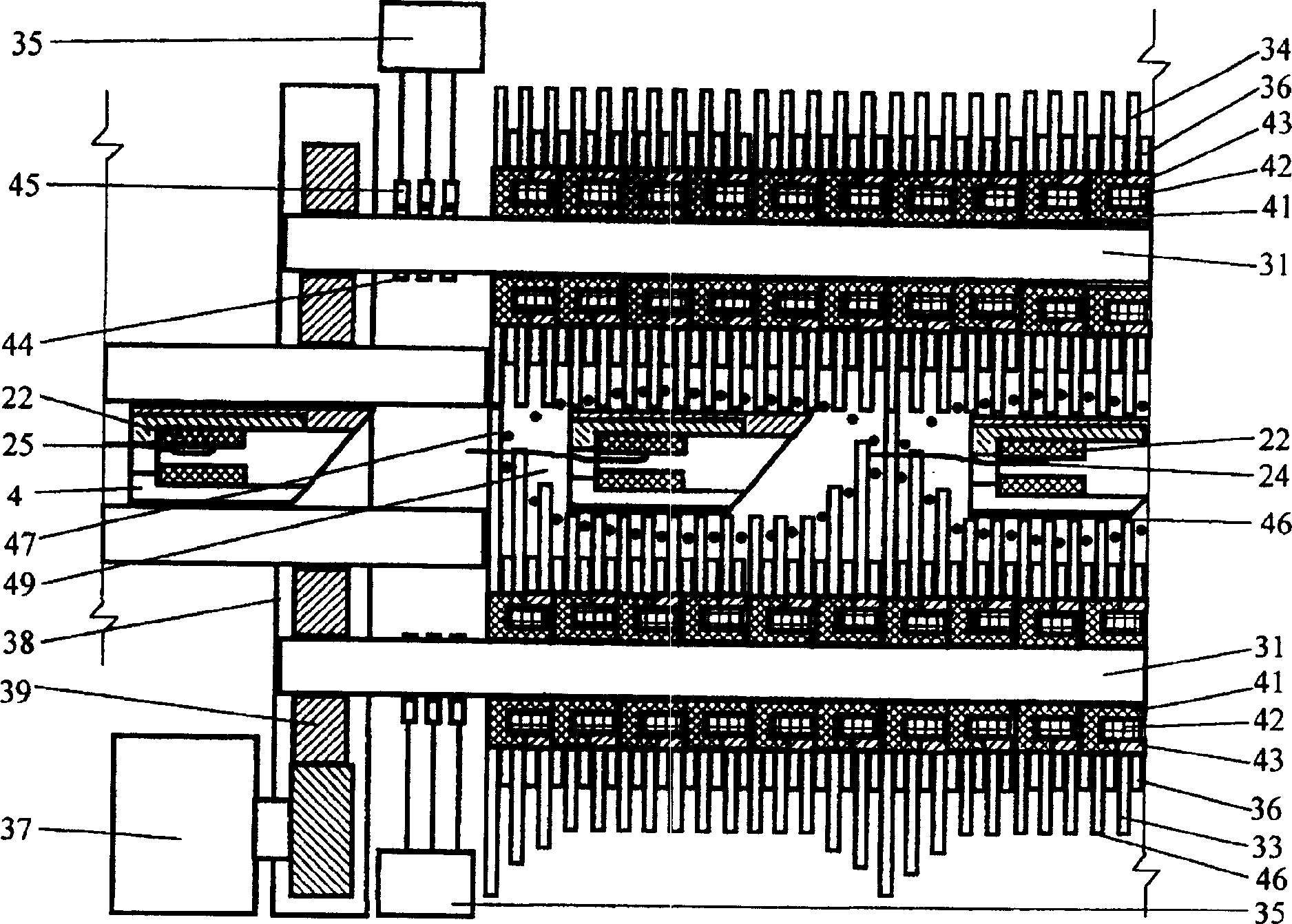

[0025] As shown in Figures 1 and 2, the magnetic shuttle multi-phase loom consists of a let-off mechanism 1, a shedding mechanism 2, a weft insertion and beating mechanism 3, a magnetic shuttle 4, a take-up mechanism 6, and a weft filling mechanism. The weft replenishing mechanism is composed of a rotary connector 5, a weft replenishing shed 7, a number of weft rewinders 10 arranged on the weft refill shed 7, a number of weft winders 9 arranged on each weft replenisher 10, and a The weft feeder 8 that stores and supplies the weft yarn to the weft winder 9 consists.

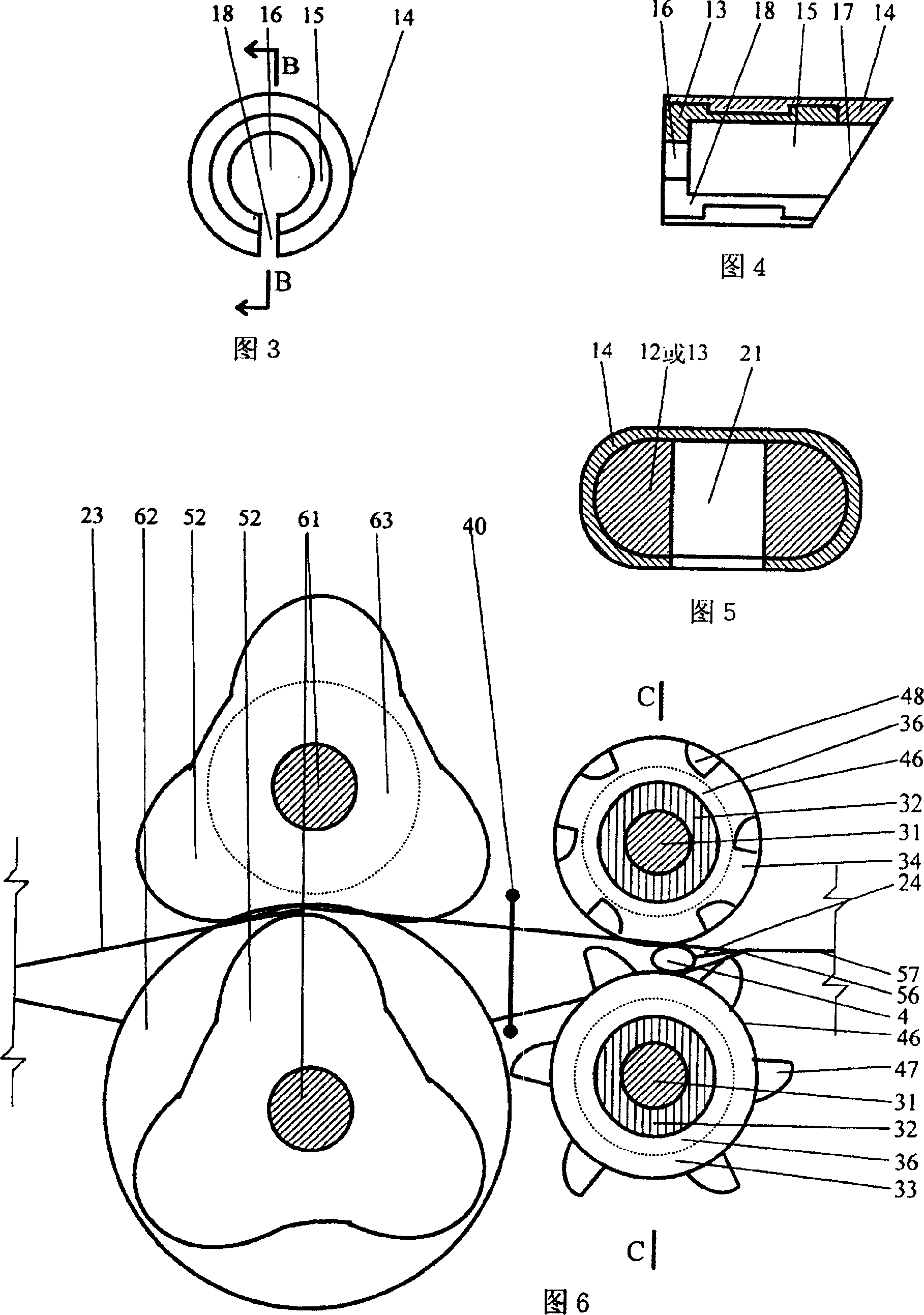

[0026] The magnetic shuttle 4 is provided with a linear motor secondary, as shown in Figures 3, 4, 5, and 15. The secondary of the linear motor is generally a permanent magnet secondary 12 made of a permanent magnet made of a permanent magnet material according to the principle of a permanent magnet synchronous motor, or an inductor secondary 13 made of a magnetically conductive material silicon steel according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com