Flexible magnet rheological tongs

A flexible fixture and magnetorheological technology, applied in the field of workpiece fixtures, can solve the problems of low degree of automation, long phase transition time, and narrow fixture adaptation surface, and achieve a high degree of automation, short phase transition time, and low self-cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

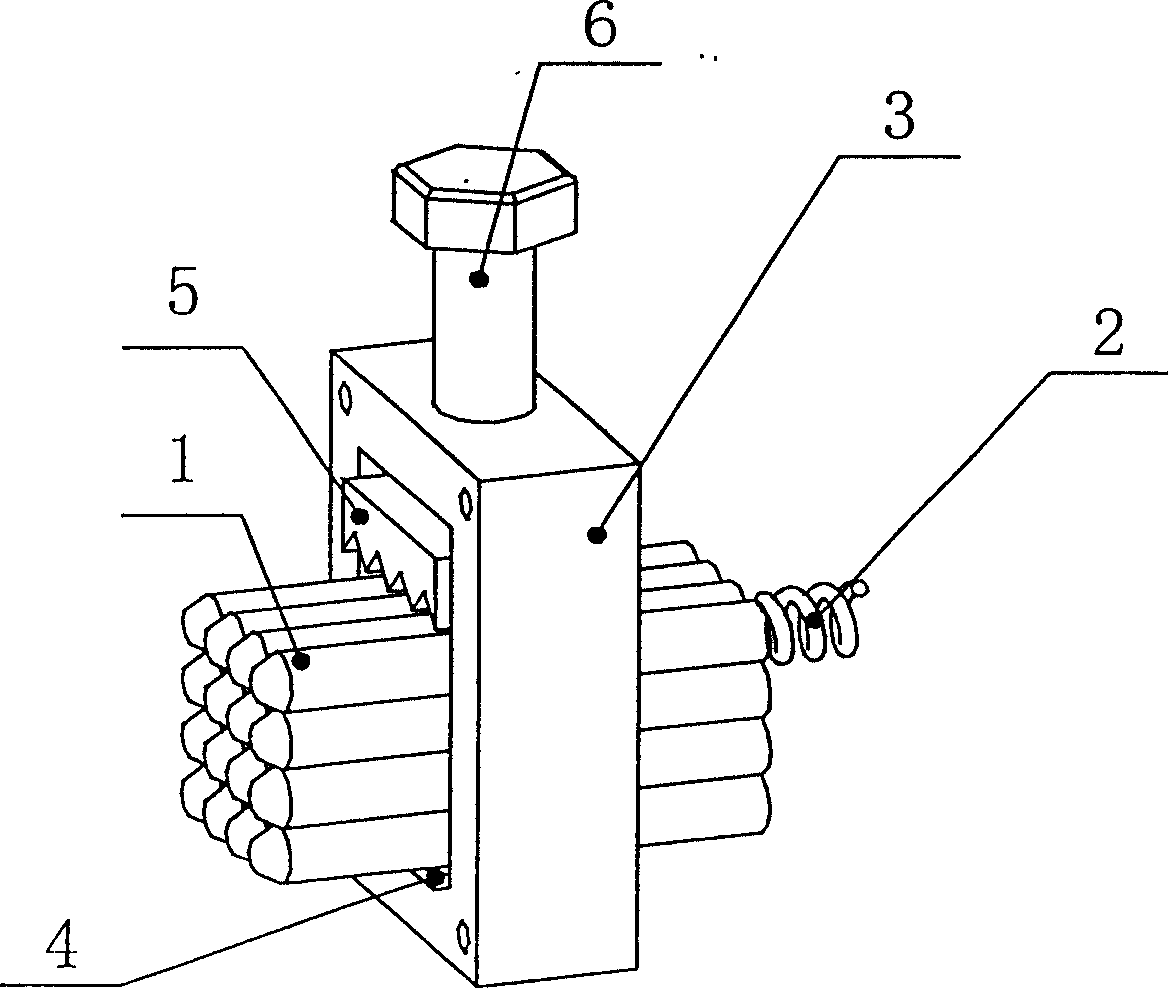

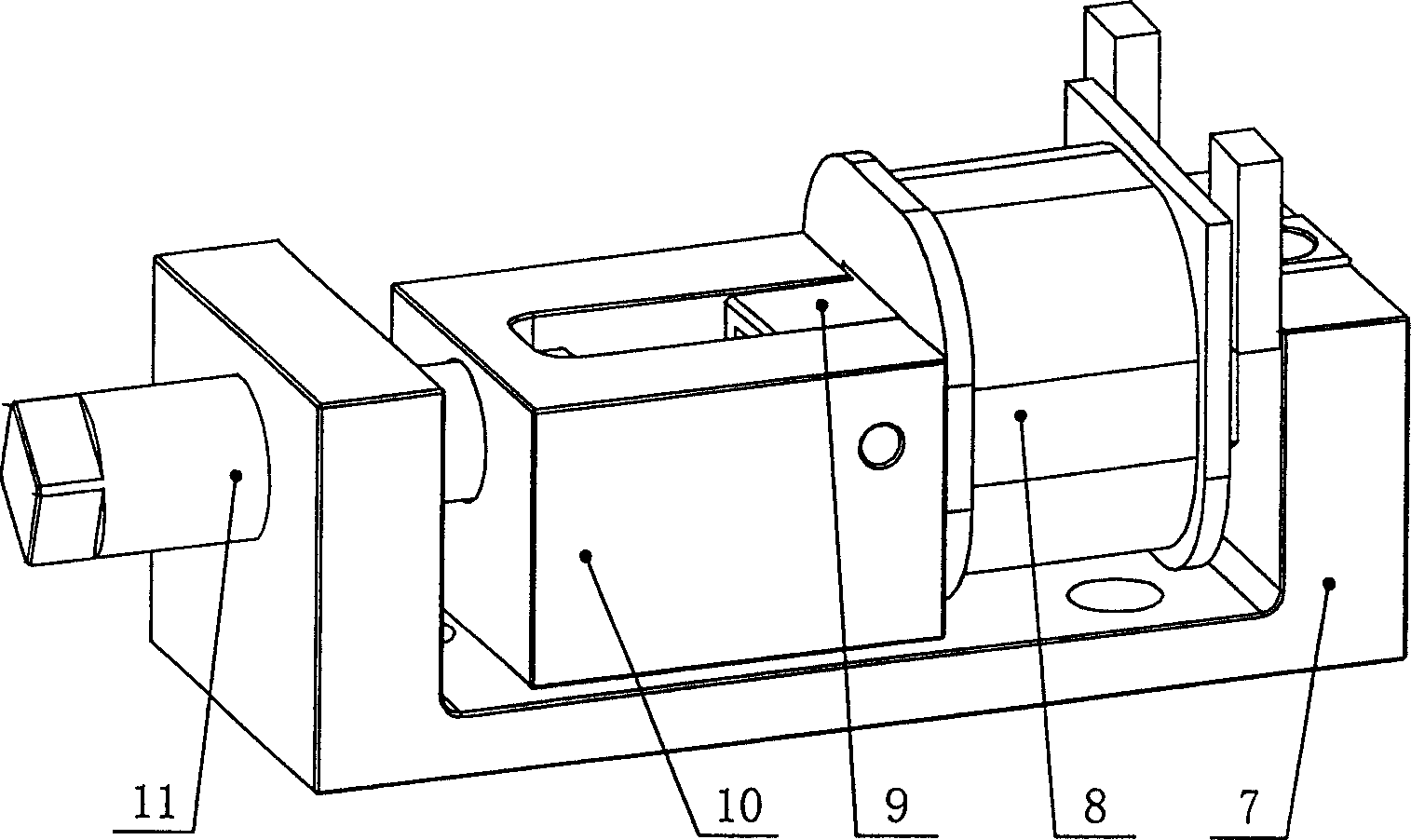

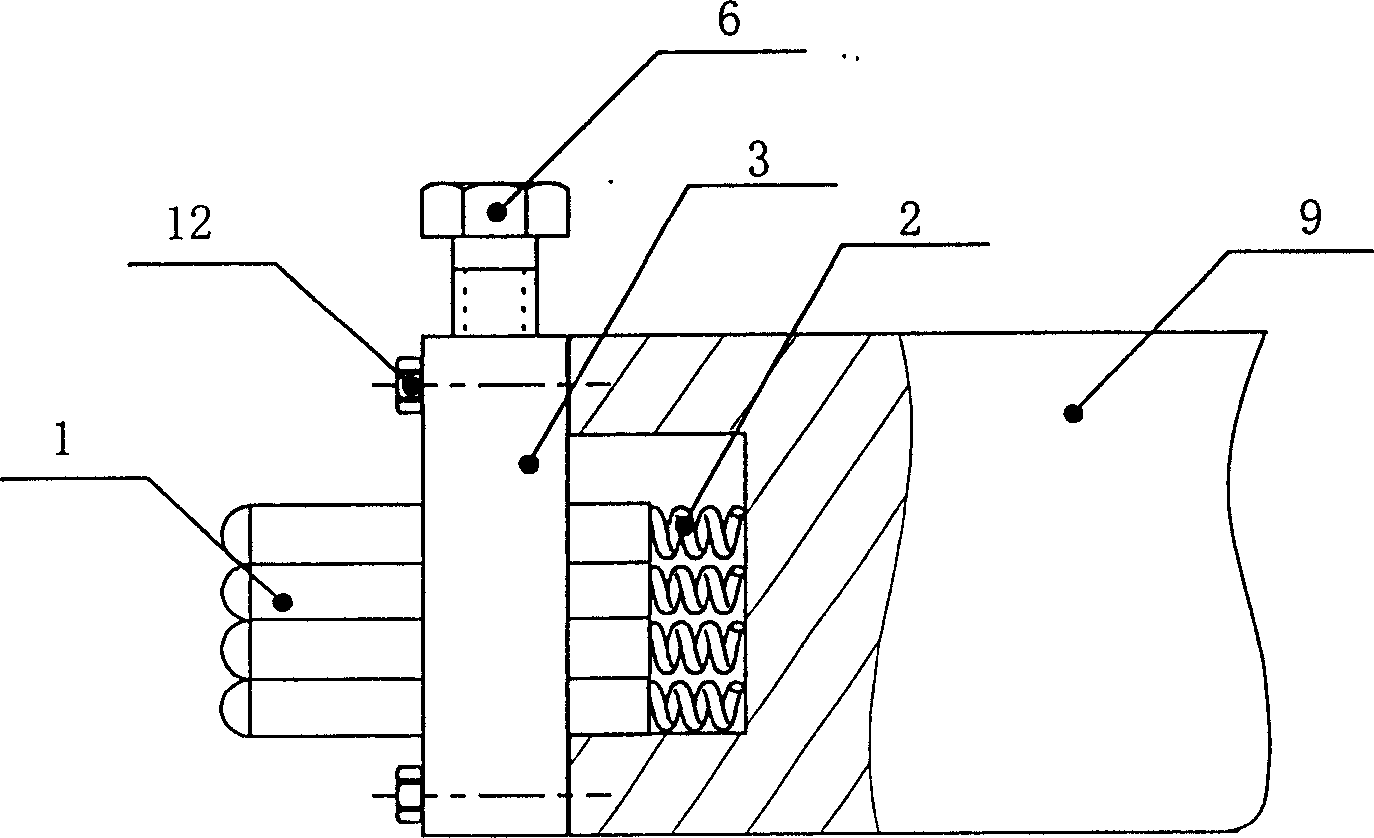

[0035]Embodiments of the present invention are as follows: column pin 1 is 16 rigid cylinders, made of 35# steel, with a size of φ3mm and a length of 30mm; the front end of the column pin is a ball head, the rear end is a flat head, and a same The compression spring 2 of the shaft, the size of the spring is φ3mm, the length is 10mm, and the material is 65# steel; the frame 3 is a rectangular ring made of 35# steel, the outer size is 20×23mm, and a vertical tight is set on the upper side of the frame. Fixed bolt 6 is used as the fastener that fixes pin, and the lower end of fixed bolt connects a lower side and is the block 5 of serration, and the inboard of frame lower side is also pasted with hard rubber layer 4 as elastic interlayer. The base 7 is a U-shaped piece made of 35# steel. The excitation part 8 and the tank 10 are placed in the groove of the base and fixed with screws. The tank is made of copper, and its inner cavity size is 20×20×23mm (length×width × high); the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com