Vibration fluidizing density grading device for granular catalyst

A technology of density classification and catalyst, which is applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalyst, solid separation, etc., to achieve the effect of convenient operation, simple structure and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

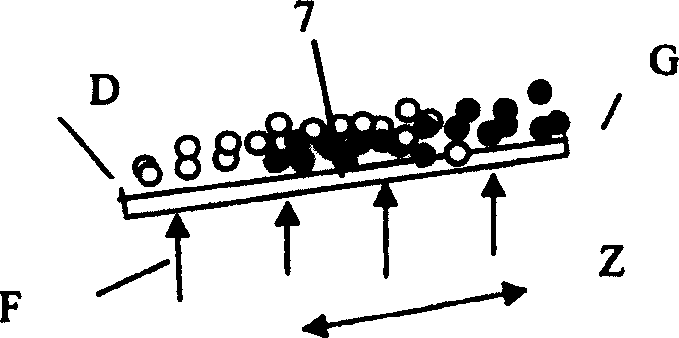

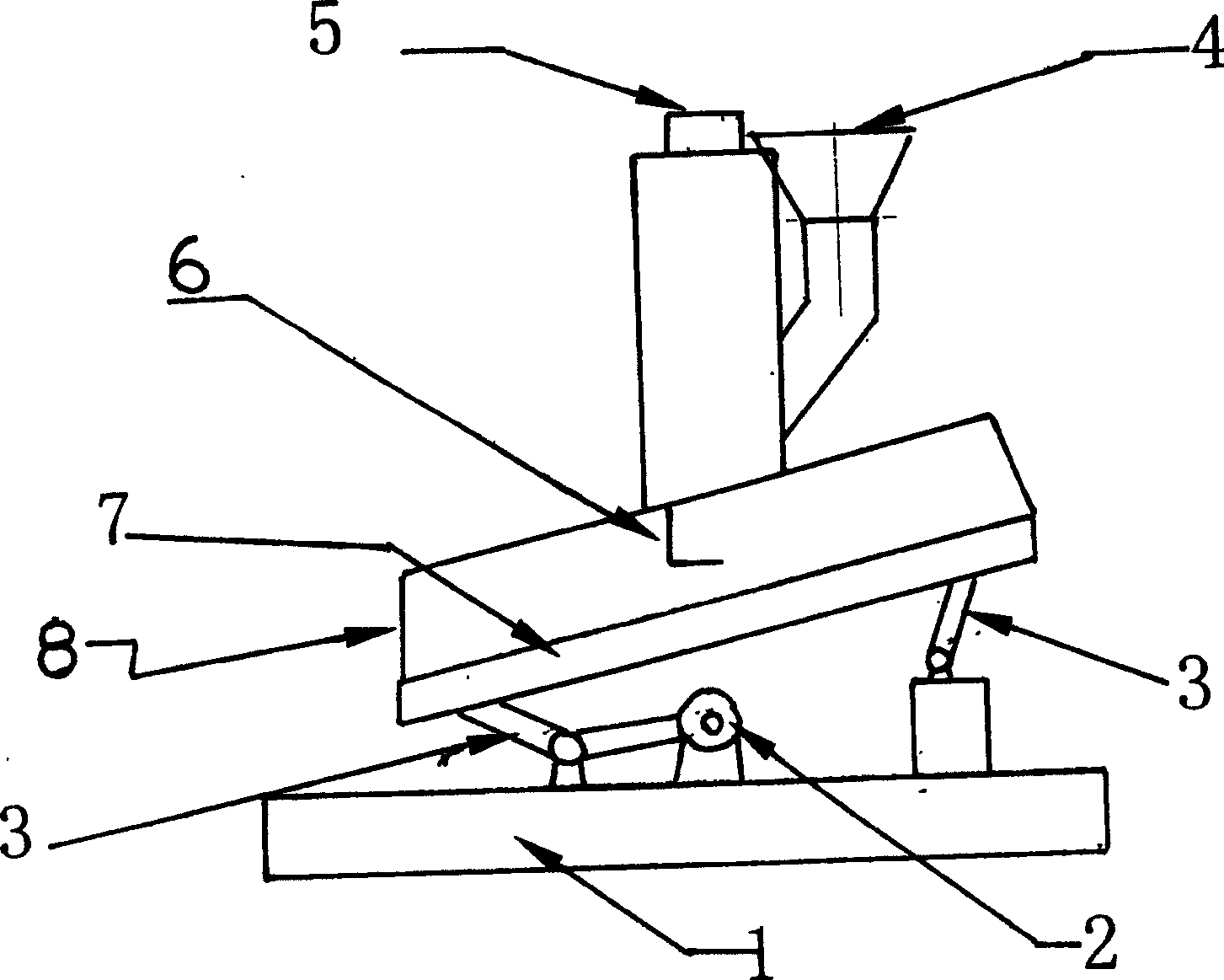

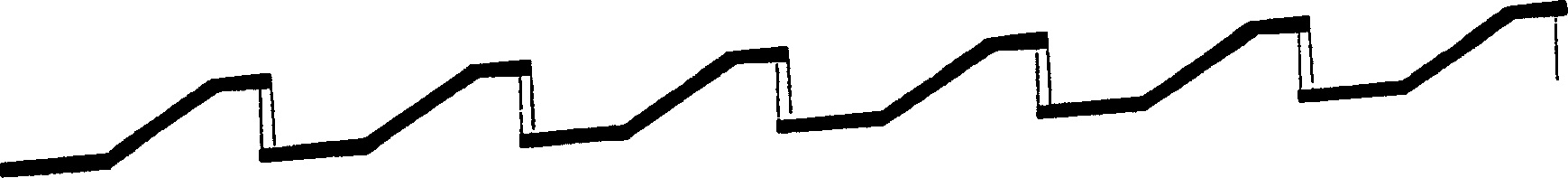

[0019] A vibrating fluidized density classifying device for granular catalysts with high carbon content and low carbon content used in a platinum reforming unit, a base 1, which mainly includes a sieve plate 7 with an inclined size of 600×1500mm, It is inclined 6° in the length direction, and the sieve plate 7 is provided with a rectangular screen hole of 0.6×15mm, and the opening rate is 20%. The sieve plate 7 vibrates in a straight line along the inclined direction of the sieve plate, the vibration frequency is 80 times / min, and the amplitude is 3mm. Vibrate together, the sealing cover 8 is connected with the suction duct through a flexible connection, and then connected with the induced draft fan through the fluidized air outlet 5 on the suction duct; a feeding hopper 4 is installed in the middle of the suction duct, and there is a The pipeline passes through the suction duct and communicates with the spreading plate 6 fixed on the top of the sieve plate 7 , the length of t...

Embodiment 2

[0022] A vibratory fluidized density classifier for high-carbon and low-carbon catalysts used in platinum reformers, which mainly includes a sieve plate 7 that is basically 600 x 1500mm inclined, inclined in the length direction 8°, the sieve plate 7 has a 0.8×20mm rectangular sieve hole, and there is a small tongue on the sieve hole, the small tongue is raised 1.0mm upwards, and the opening rate is 30%. 2 connected, start the motor 2 to make the sieve plate 7 vibrate linearly along the inclined direction of the sieve plate, the vibration frequency is 90 times / min, and the amplitude is 2mm; the sieve plate 7 is equipped with a sealing cover 8, and the sealing cover 8 is fixed on the On the plate 7, it can vibrate together with the sieve plate 7, and the sealing cover 8 is connected with the suction duct through a soft connection, and then connected with the induced draft fan through the fluidized air outlet 5 on the suction duct; the middle part of the suction duct is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com