Hydraulically controlled pressure releaf valve for high-pressure reactors

A high-pressure reactor and pressure reducing valve technology, which is applied in fluid pressure control, electric fluid pressure control, and non-electrical variable control, etc. Fast cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

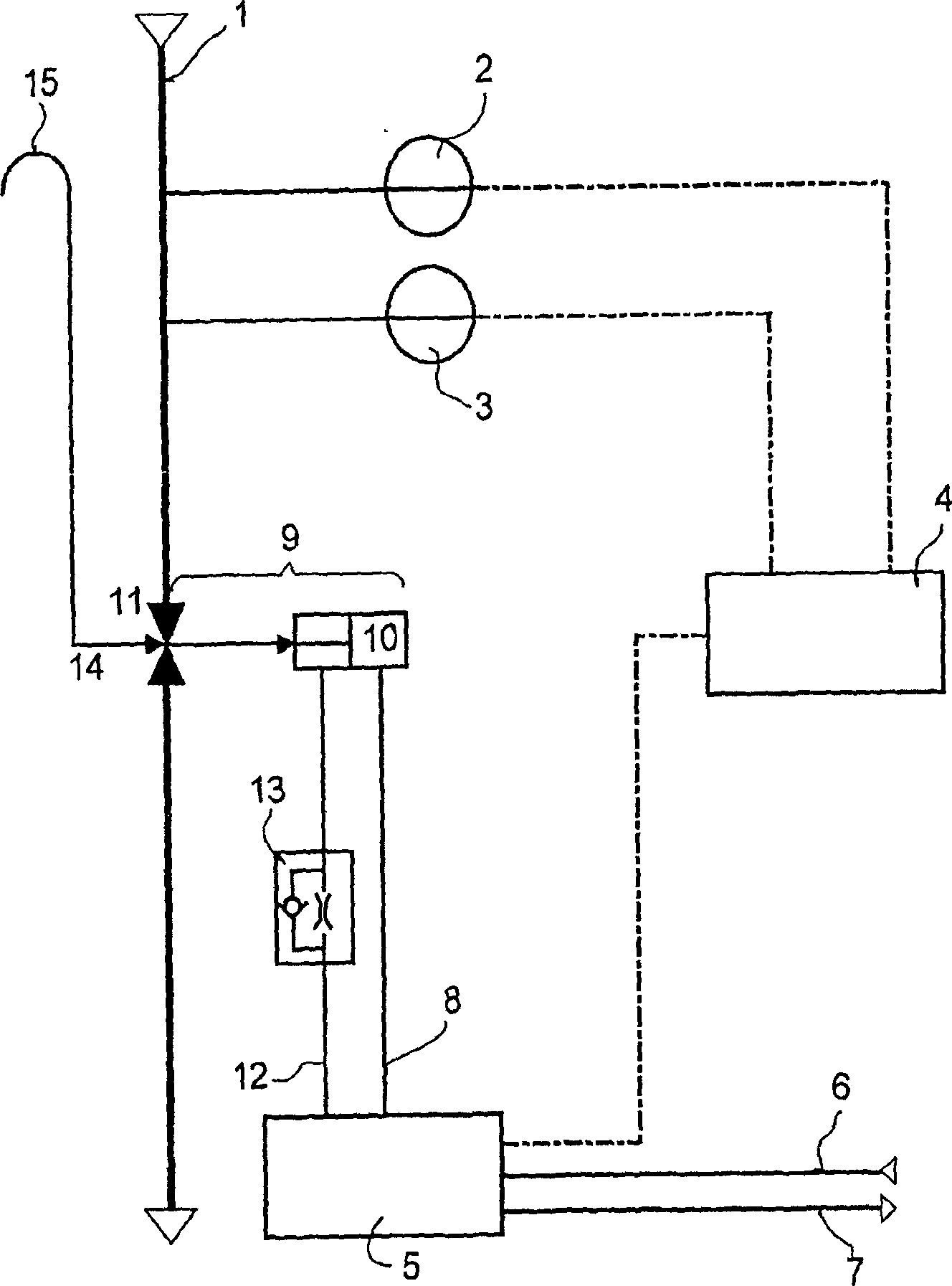

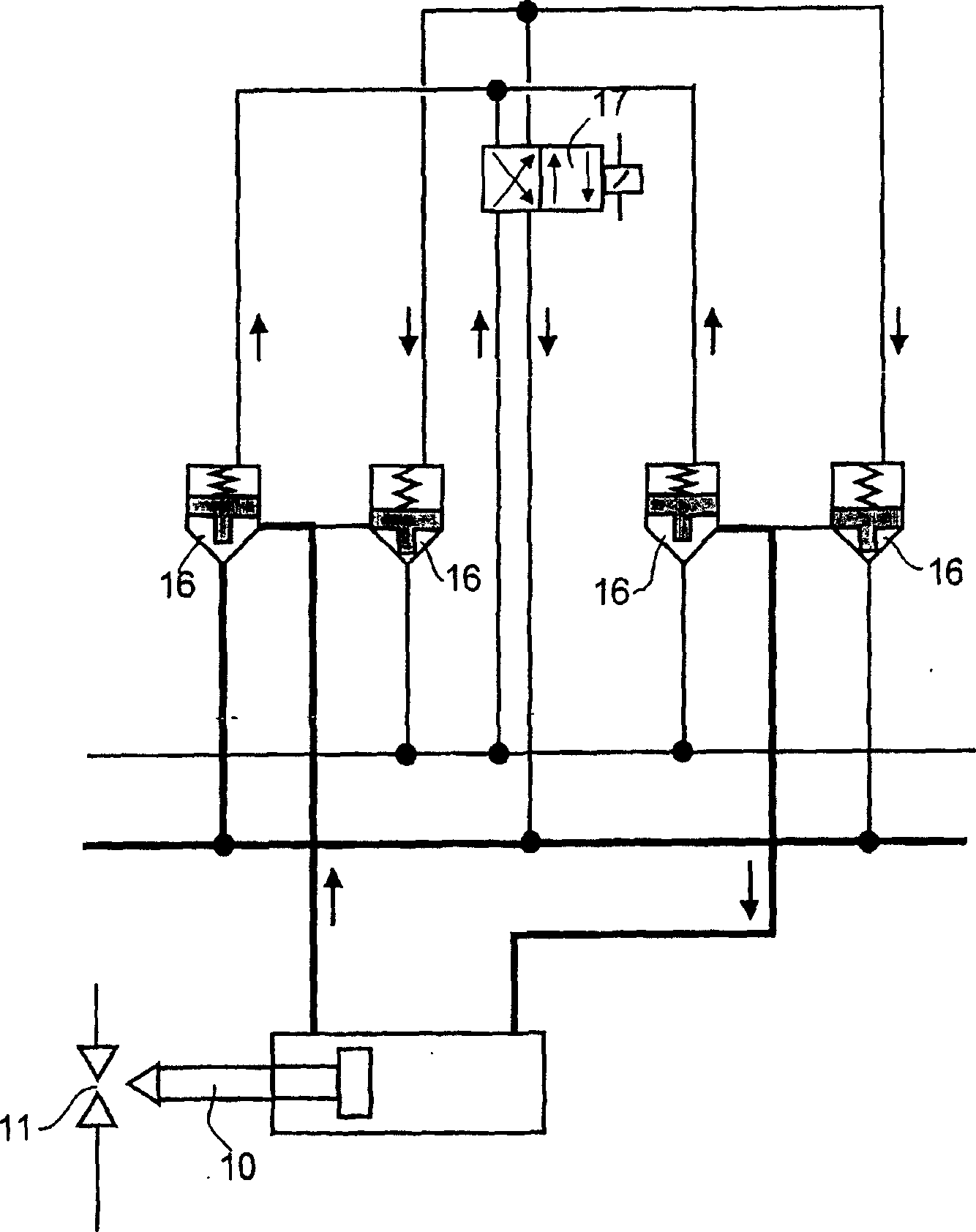

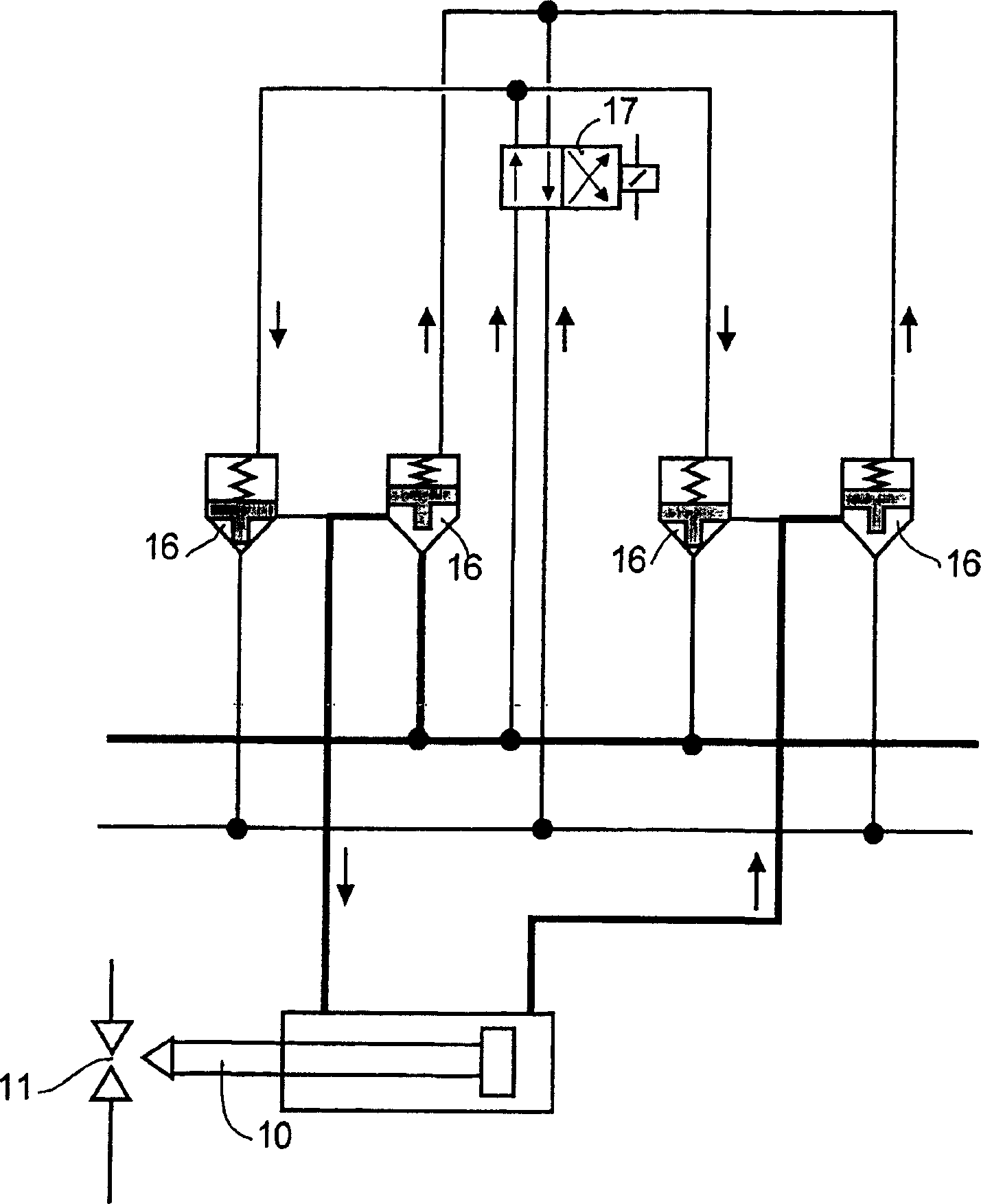

[0026] figure 1 A high-pressure reactor 1 is shown, on which a measuring device 2 for the pressure and a measuring device 3 for the temperature are arranged. An electronic signal is sent from the measuring device 2, 3 to the electronic control system 4 when a predetermined temperature or predetermined pressure is exceeded. The electronic control system sends electronic signals to the hydraulic control unit 5 . A supply pipe 6 and a return pipe 7 of hydraulic fluid are mounted on the hydraulic control unit. Suitable hydraulic fluids are generally commercially available hydraulic oils. A signal to the hydraulic control unit 5 causes one or more valves of the hydraulic control unit 5 to open. The hydraulic fluid is thereby forced to flow through the connecting conduit 8 in the form of a tube in the direction towards the hydraulic system 9 . Accordingly, the movable piston block 10 moves, thereby opening the pressure relief valve 11 . In order to close the pressure relief val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com