Apparatus for measuring film thickness formed on object, apparatus and method for measuring spectral reflectance of object, and apparatus and method of inspecting foreign material on object

A technology of film thickness and measuring device, which is applied to measuring device, optical device, phase influence characteristic measurement, etc., can solve the problems of small measurement area, impossible to achieve high-precision film thickness measurement, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

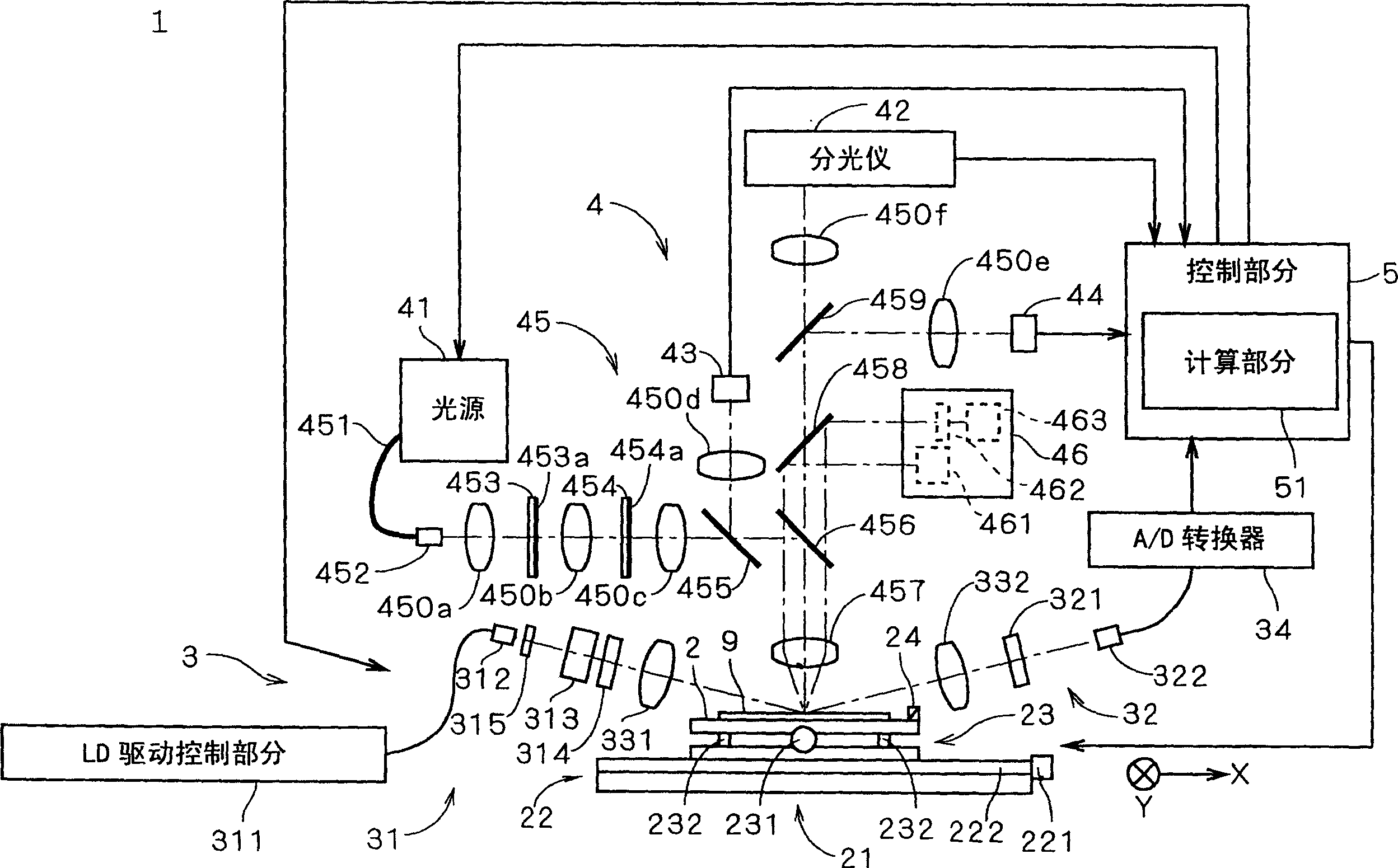

[0027] figure 1 is a schematic configuration diagram showing a film thickness measuring device 1 according to a first preferred embodiment of the present invention. Thin film thickness measuring device 1 comprises: workbench 2, is provided with semiconductor substrate (hereinafter referred to as " substrate ") 9 on it, forms multilayer thin film (this thin film can be monolayer) on this substrate; The polarimeter 3 is used to obtain the information of performing ellipsometry on the film on the substrate 9; the light interference unit 4 is used to obtain the spectral intensity of the light (reflected light) from the substrate 9; the control part 5 is controlled by the user CPU for various calculations, memory for storing various information, etc.;

[0028] The ellipsometer 3 has: a light source unit 31 for emitting polarized light to the substrate 9; and a light receiving unit 32 for receiving reflected light from the substrate 9 to obtain the polarization state of the reflect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com