Producing process for extracting hydrolytic drying materials and starch by yellow ginger

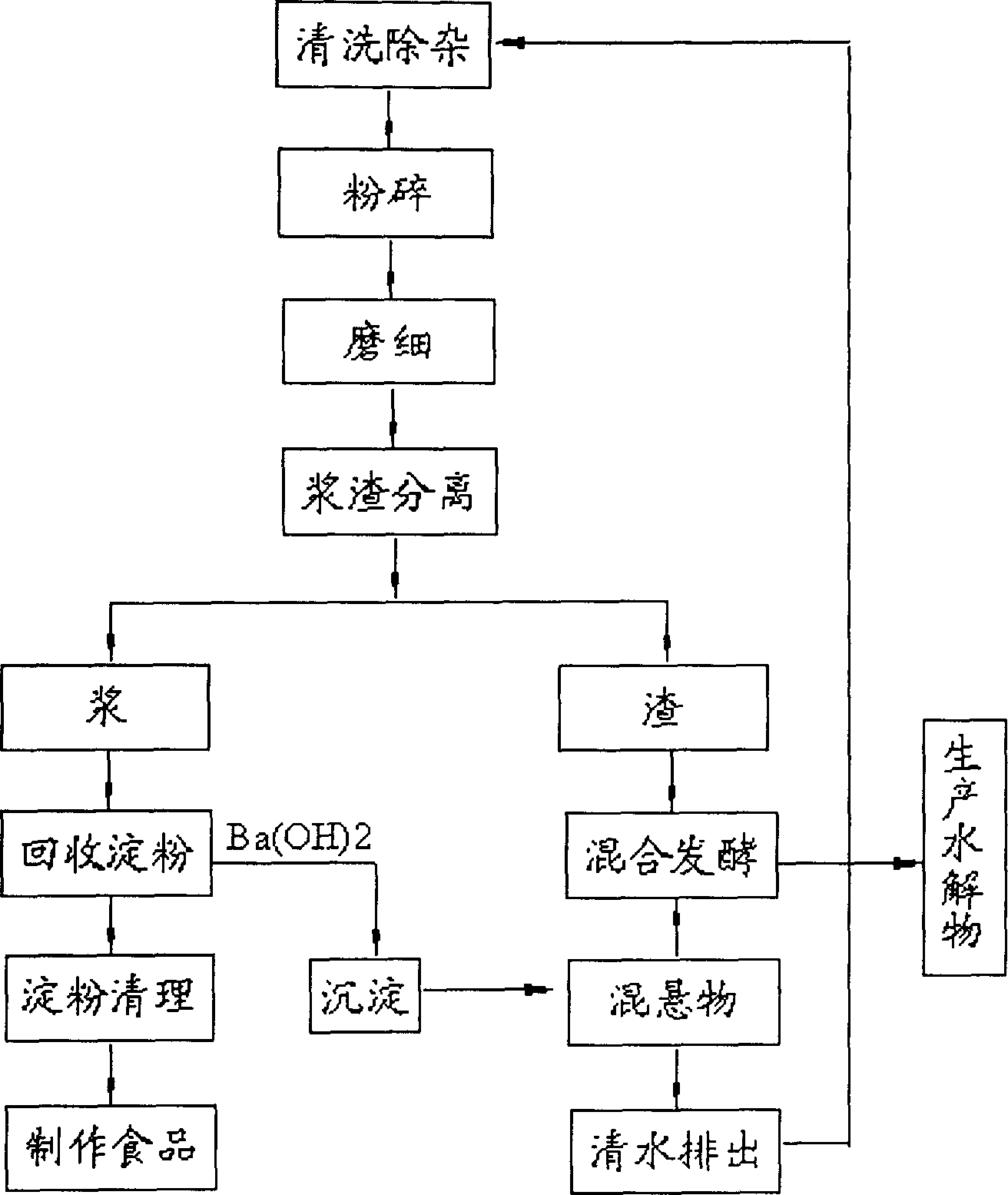

A production method and a dry matter technology are applied in the field of production technology for extracting and hydrolyzing dry matter and starch from turmeric, can solve the problems of high saponin recovery, large investment, no starch utilization, etc., improve saponin yield and reduce environmental pollution , the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Take 2 kg of turmeric, first use a vibrating sieve to remove soil impurities from the rhizome of turmeric, soak it in water for 8-10 hours, and then use a washing machine to wash it under high pressure. Due to the quality requirements of starchy food, the cleaner the cleaning, the better. After cleaning, add water and grind to below 8 mesh with existing turmeric processing plant crushing equipment, and use a refiner with water to grind to below 60 mesh to obtain 5 kg of mixed solution.

[0028] 2) The above-mentioned ground turmeric is put into a 100-mesh filter cloth to squeeze and filter, and 0.89 kg of turmeric fiber slag is separated, with a moisture content of 68.3% and an absolute dry weight of 0.28213 kg.

[0029] 3) Pour the filtered slurry into a pot, add 0.4% edible lactic acid and stir, and settle for 2.5 hours. The slurry has two layers of water, and pour the upper layer suspension into another pot, add water to wash the lower layer of starch, and then pr...

Embodiment 2

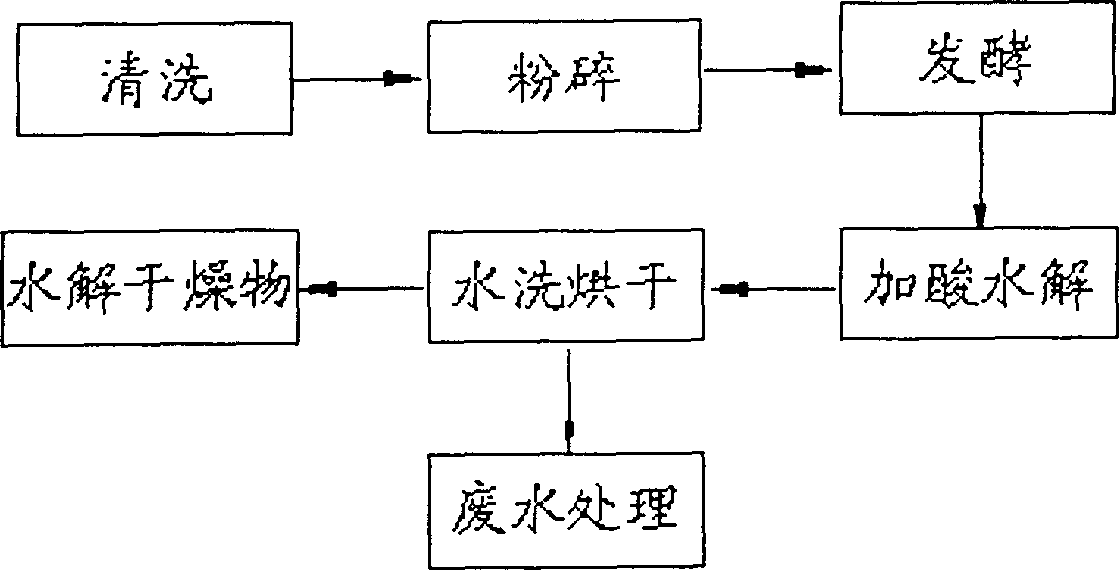

[0052] Xunyang County Hengyuan Biochemical Co., Ltd. selected 3 tons of two-year-old turmeric from Ganxi Town, Xunyang County, and divided it into two parts on average. figure 2 Process production is compared, and a part is produced by process of the present invention, and the present invention extracts and recovers 141kg of starch, and carries out saponin recovery comparative experiment.

[0053] The experimental results are as follows:

[0054] The amount of saponin extracted by the process of the present invention (kg) The amount of saponin extracted by the existing process (kg)

[0055] 11.95 11.77

[0056] The saponin obtained by the above two processes has been tested, and all the indicators are in line with the local yam saponin standard of Shaanxi DB2184-85.

[0057] The enterprise has an existing production scale of 60 tons of saponin hydrolyzate per year, and the existing production process is transformed by the process of the present invention. 1. 900 tons of star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com