Cereal sorting system and roll sorting machine

A screening machine and grain technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of oil splash, pollution, deviation of screening accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following examples illustrate the embodiments of the grain screening system of the present invention, and these descriptions are only examples, and are not limited to the illustrated content.

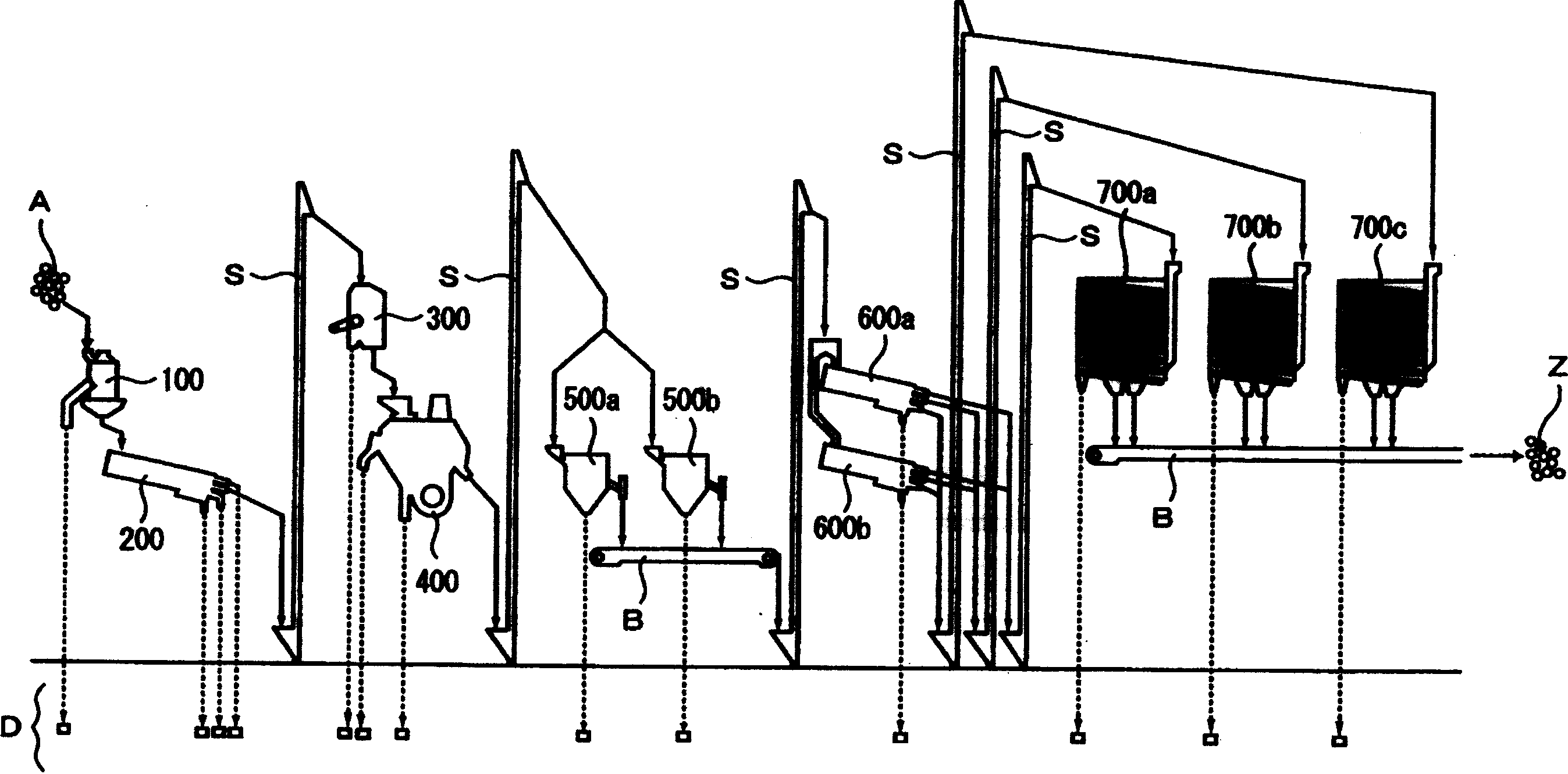

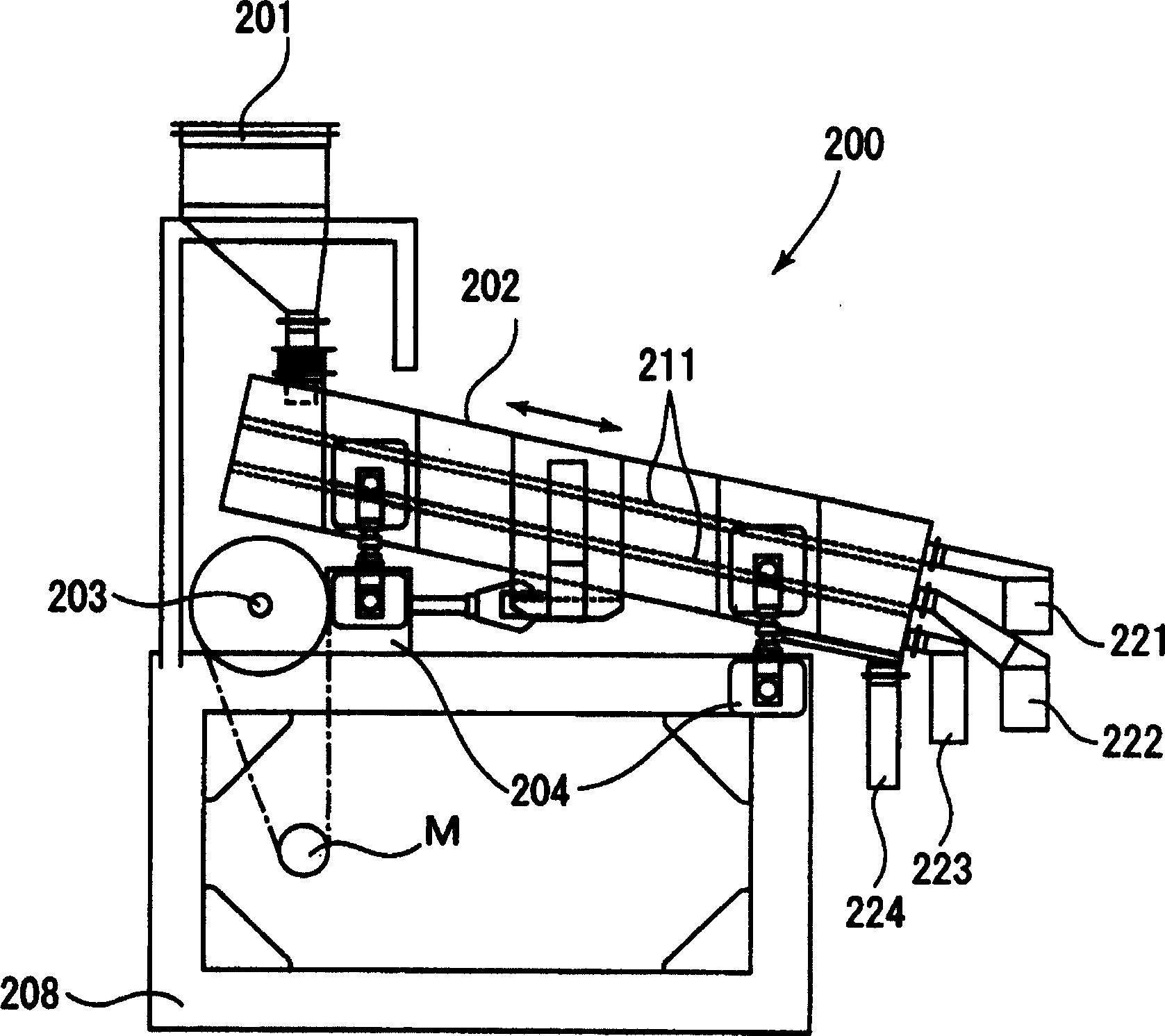

[0041] exist figure 1 Among them, A is the screening object of the grain screening system of the present invention, that is, the grain raw material, D is the foreign matter screened out in each process, S is the elevator used to lift the grain raw material A between the various processes, and B is the transport of the grain raw material A is the belt conveyor, and Z is the final product after the screening process.

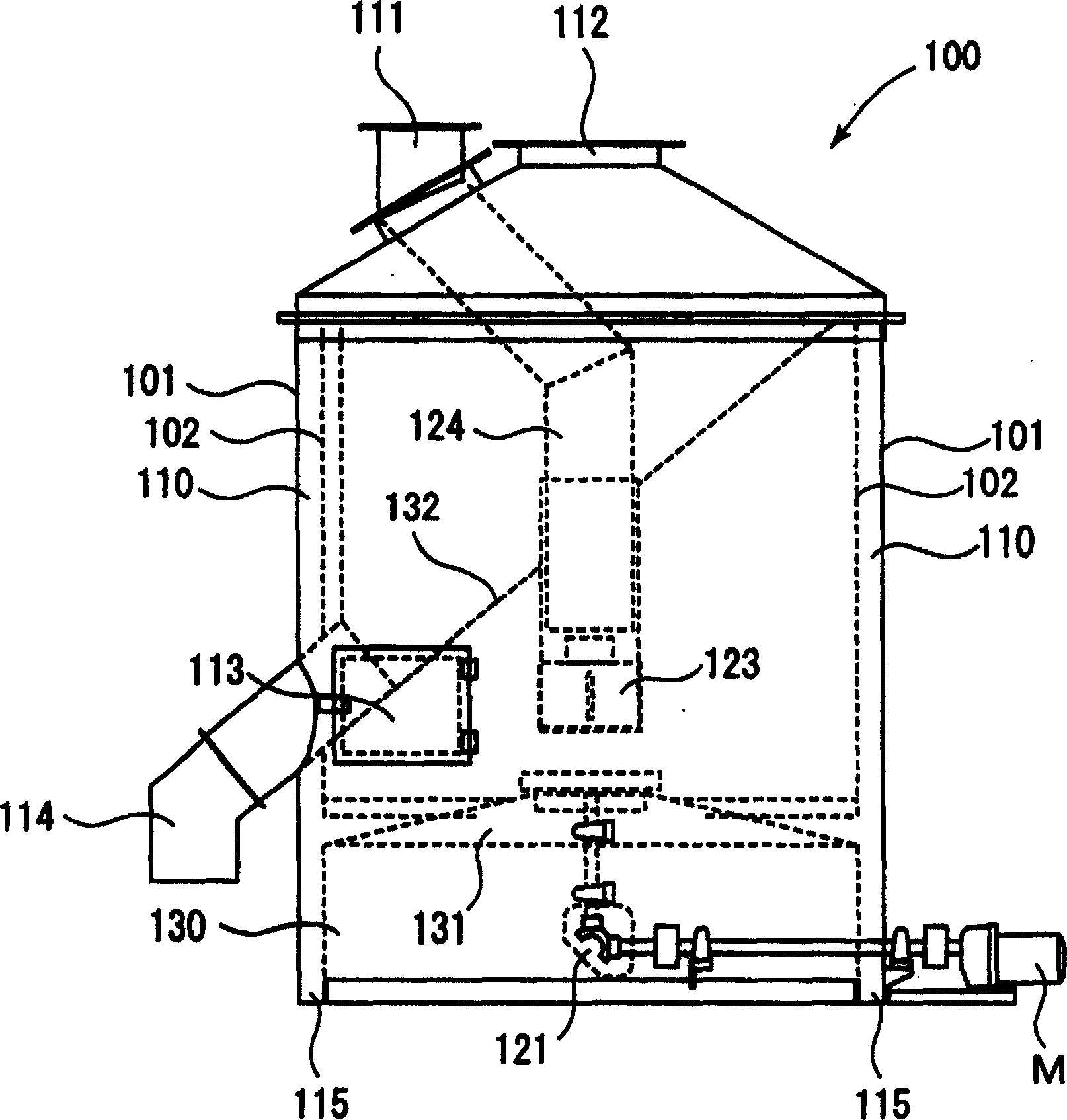

[0042] Reference numeral 100 is a suction type air sieving machine for sifting out light foreign matter from grain raw material A and implementing an air sifting process. This suction-type wind screener 100 removes light foreign matter (dust, skin, small impurities, etc.) by the suction force of the wind. As this air sieving machine, a well-known air sieving ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com