Magnet assembly and method for making same, small sized electric appliance using same

An assembly and magnet technology, which is applied in the manufacture of inductors/transformers/magnets, electromechanical devices, and the manufacture of stator/rotor bodies, etc., which can solve the problems of thick terminals, difficult reflow soldering, and notch corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Detailed description of the embodiment

[0033] Each embodiment will be described in order below. However, sometimes the same symbols are attached to the parts that are the same as in the past in the embodiment, and the description thereof is omitted.

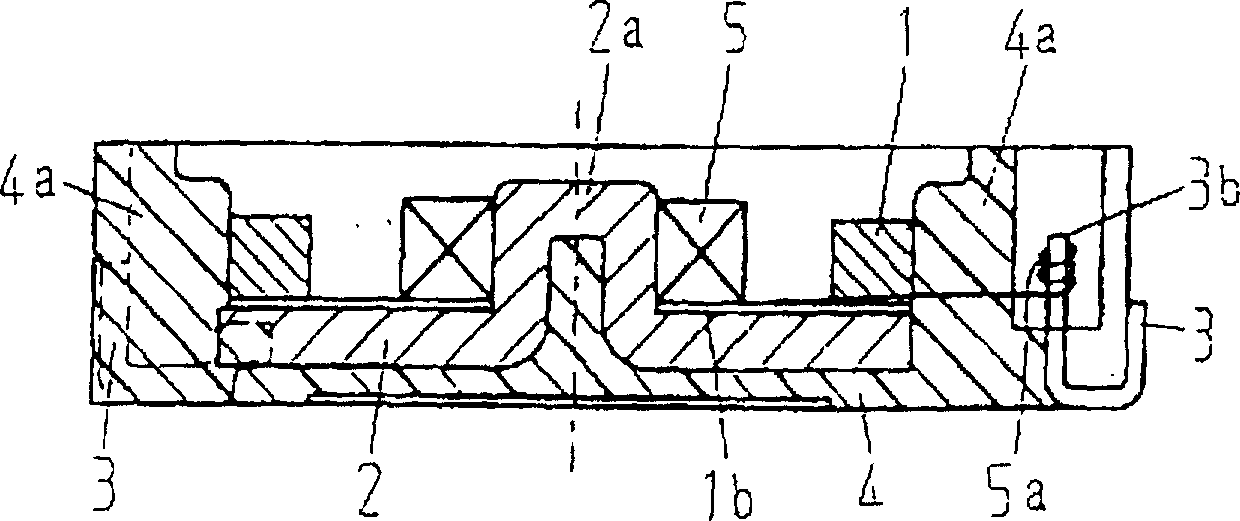

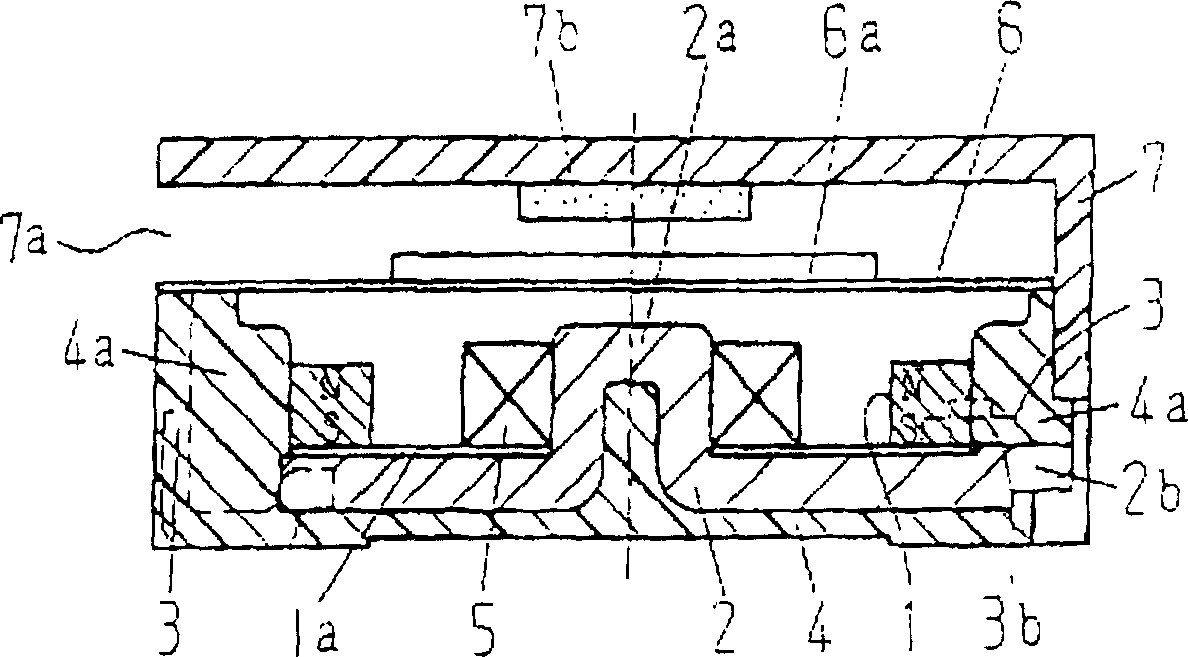

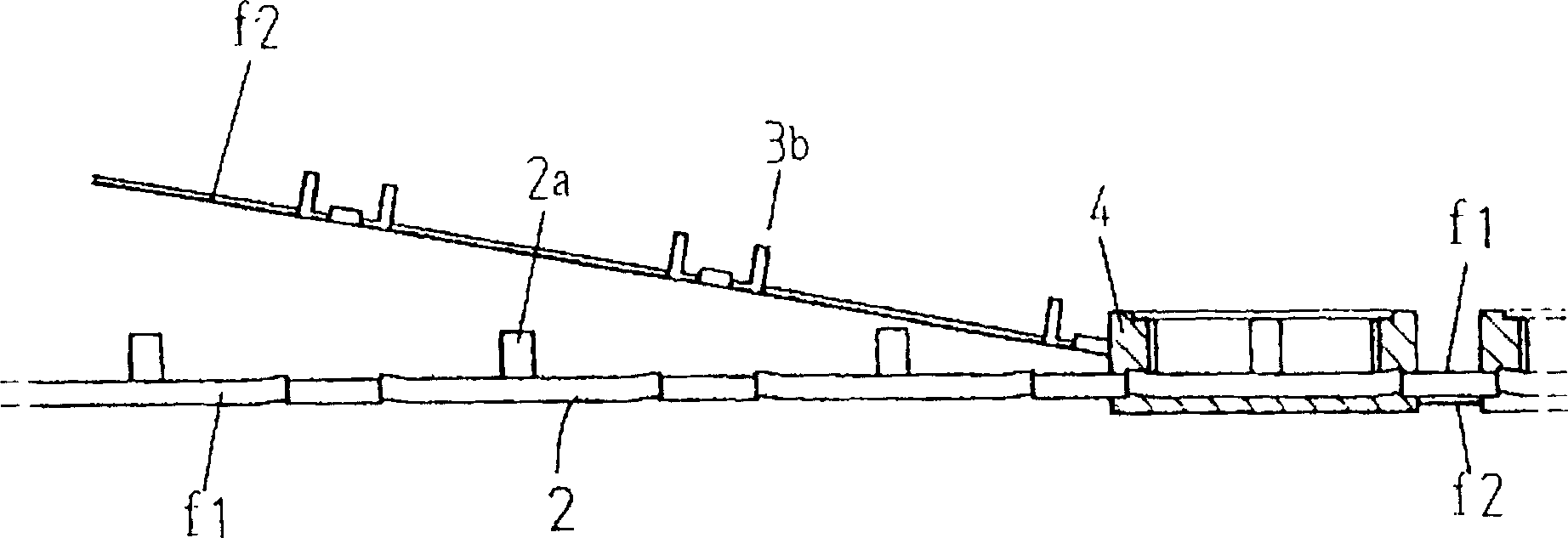

[0034] figure 1 It is the first embodiment of the present invention applicable to the magnet assembly of the electroacoustic transducer, that is to say, a yoke composed of a magnetic body with a shallow cylindrical magnet 1 installed through the acrylic double-sided adhesive material 1b for heat insulation The iron 2 raises the pole shoe 2a upwards in the center. Such as image 3 As shown, the yoke 2 is formed in a connected state from a first lead frame made of a galvanized steel sheet with a thickness of 0.35 to 0.5 mm. The power supply terminal 3 is formed in a connected state at the same pitch as the above-mentioned yoke on the second lead frame composed of a thin plate having good corrosion resistance and good s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com