Manufacturing method of nanometer calcium carbonate latex gloves

A technology of nano-calcium carbonate and latex gloves, which can be applied to protective clothing, etc., can solve problems such as a large amount of sweat, inability to effectively prevent virus penetration, and tear strength that cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

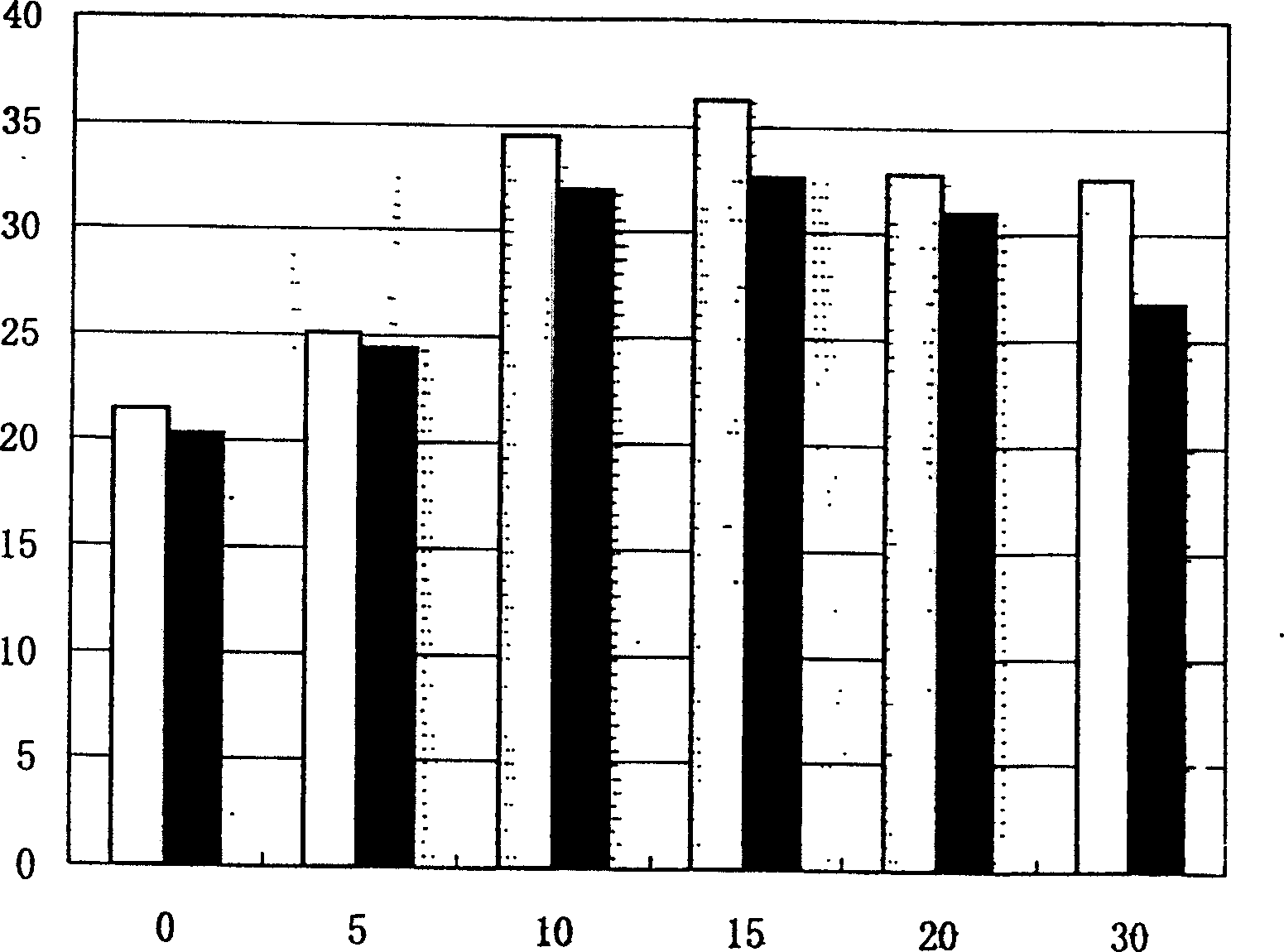

[0020] Take calcium carbonate with a particle size of 15-40 nanometers and disperse it evenly in soft water with dispersing equipment to make a relatively stable water-based dispersion. The content of nano-calcium carbonate in the water-based dispersion is controlled at 23-40%. Then the prepared nano-calcium carbonate aqueous dispersion and other conventional ingredients are uniformly dispersed in pre-vulcanized or compounded latex under stirring. The ratio of nano-calcium carbonate and latex is 1: 9 (dry ratio). Stir while heating up to make it fully vulcanized and compounded, and the latex after vulcanized and compounded evenly contains nano-calcium carbonate components. The latex added with nano-calcium carbonate is vulcanized and parked, and then the conventional molding process, including on-line chlorination, on-line polymer coating and post-treatment process, is made into finished nano-calcium carbonate latex gloves.

[0021] To the nanometer calcium carbonate latex glo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com