A self-assembly preparation method of a micro-nano multi-level column structure

A multi-level column, self-assembly technology, applied in microstructure devices, manufacturing microstructure devices, microstructure technology and other directions, can solve the problems of high processing cost, difficult to obtain nanostructure, high cost, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

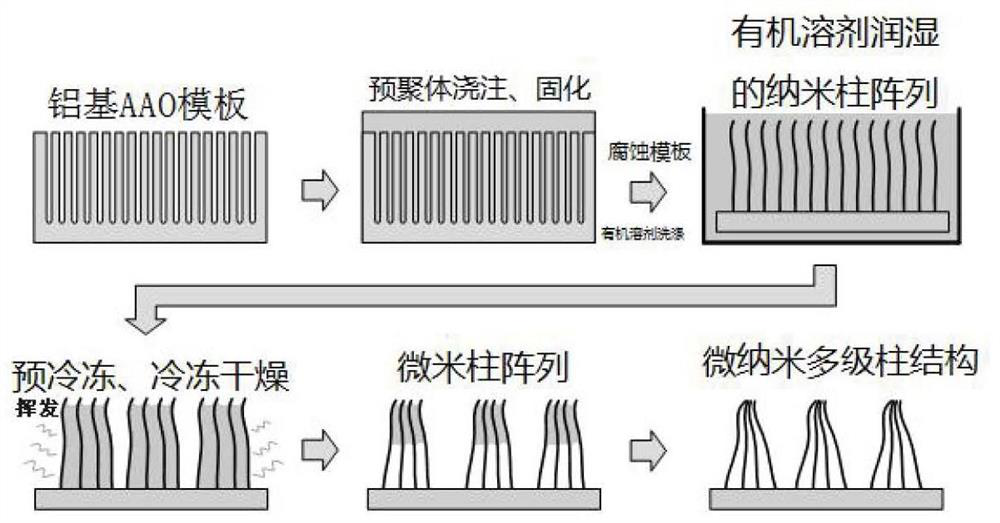

[0029] The invention provides a self-assembly preparation method of a micro-nano multi-level column structure, comprising the following steps:

[0030] After cleaning the aluminum-based AAO template, an organic film is evaporated on the surface of the aluminum-based AAO template, and then the prepolymer is poured onto the surface of the aluminum-based AAO template and cured to obtain a cured sample; the prepolymer is poured to exceed the hole height of the aluminum-based AAO template;

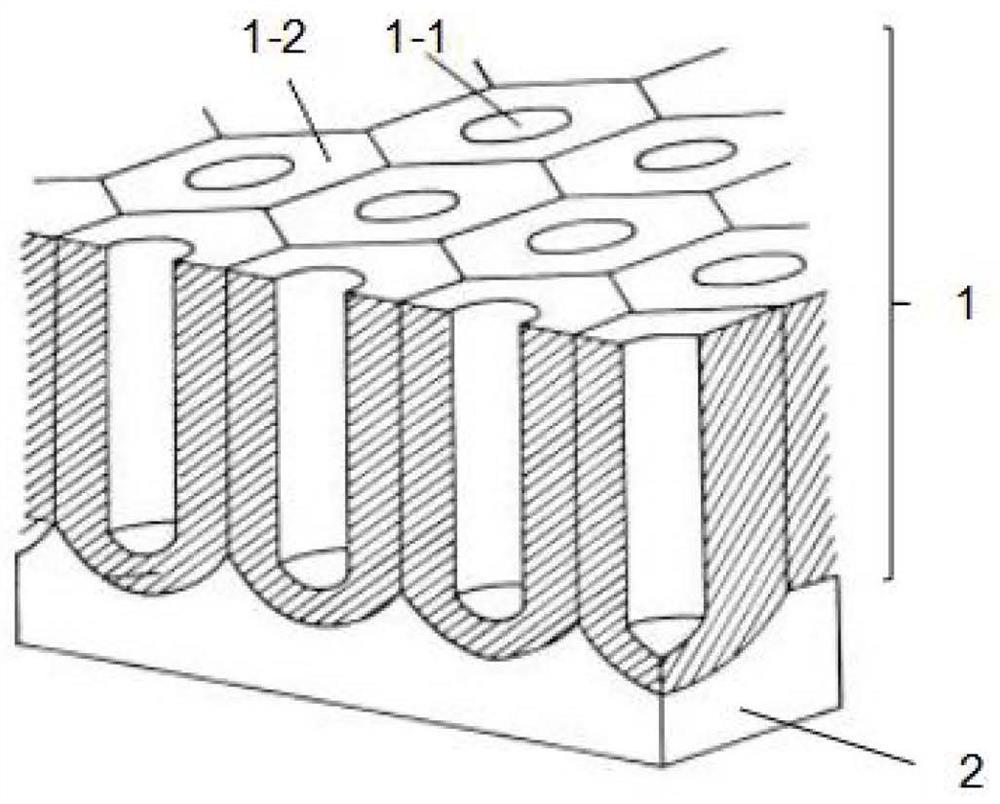

[0031] removing the aluminum-based AAO template in the cured sample to obtain a nanopillar array;

[0032] The nano-pillar array is washed with an organic solvent to obtain a nano-pillar array wetted by an organic solvent;

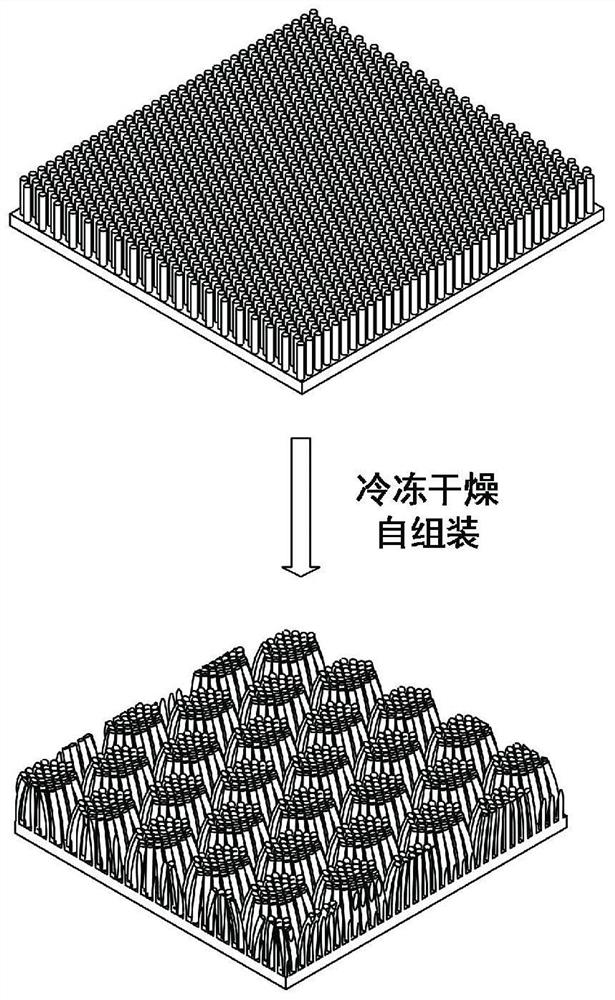

[0033] The organic solvent-wetted nano-pillar array is sequentially pre-frozen and freeze-dried to obtain the micro-nano multi-level column structure.

[0034] After cleaning the aluminum-based AAO template, an organic film is evaporated on the surface of the aluminum-bas...

Embodiment 1

[0062] Step 1: After ultrasonically cleaning the aluminum-based AAO template in deionized water, ethanol and acetone in sequence, a Parylene film (with a thickness of 50 nm) was evaporated on the surface of the aluminum-based AAO template; Dow Corning 184 The prepolymer and the curing agent are fully stirred at a mass ratio of 10:1 and then degassed to obtain a prepolymer; the prepolymer is poured onto the aluminum-based AAO template surface ( The degree of pouring of the polymer fluid exceeds the height of the hole by 5 mm), then it is put into a vacuum desiccator for 20 minutes of vacuuming, taken out and placed in a hot oven with a temperature of 75 ° C, and heated and cured for 1.5 hours to obtain a cured sample;

[0063] Step 2: Immerse the cured sample in NaOH solution with a mass fraction of 5%, let it stand for 10 minutes, take out the cured sample and rinse with deionized water; then immerse the sample in CuCl with a mass fraction of 70% 2 The solution was dissolved i...

Embodiment 2

[0068] The difference from Example 1 is that the nano-pillar array wetted with tert-butanol in step 4 is pre-frozen in a refrigerator with a temperature of -18 ° C to obtain a PDMS micro-nano-pillar array surface with a self-assembly scale of about 5-10 μm. Micro-nano multi-level pillar structure.

[0069] Image 6 The electron microscope photograph under 5200 magnifications of the micro-nano multi-level column structure obtained in this embodiment; Figure 7 The electron microscope photograph of the micro-nano multi-level column structure obtained in this example at a magnification of 19,000. from Image 6 and Figure 7 It can be seen that the nanopillar array self-assembles during the freeze-drying process to form many micron-scale columnar structures with an average size of 6μm×6μm area, and there are certain gaps between the nanopillars, and no clusters are very close.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com