Preparation method of heterogeneous cross-linked sodium hyaluronate gel

A technology of sodium hyaluronate and gel, applied in the field of biomedical materials, can solve the problems of difficult control of the final concentration of sodium hyaluronate, low removal efficiency of residual test machines, adverse effects of gel properties, etc., so as to avoid adverse effects. , good viscoelasticity, high cross-linking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

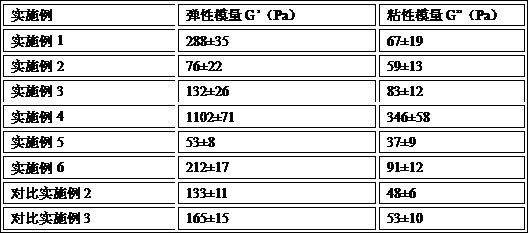

Embodiment 1

[0028] Mix 16ml of methanol and 4ml of water to obtain an alcohol-water solution with a methanol volume fraction of 80%, take 10ml of the alcohol-water solution, add 1g of sodium hyaluronate with a molecular weight of 1.3 million, and stir magnetically to form a suspension; Add 0.2g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), keep stirring, and react at 4°C for 90min; filter the reaction product with a Buchner funnel, and use 50ml Wash with ethanol for 3 times, collect the powder, and dry it in a blast drying oven at 40°C; disperse the dried powder in 50ml of sodium chloride solution with a pH of 6.0 and an osmotic pressure of 250mOsm / L to obtain a heterogeneous cross Sodium hyaluronate gel.

Embodiment 2

[0030] Mix 99ml of ethanol and 1ml of water to obtain an alcohol-water solution with a volume fraction of 99% ethanol, take 50ml of the alcohol-water solution, add 1g of sodium hyaluronate with a molecular weight of 2 million, and stir magnetically to form a suspension; Add 0.2g EDC, keep stirring, and react at 35°C for 60min; filter the reaction product with Buchner funnel, wash with 50ml ethanol for 3 times, collect the powder, and put it in a vacuum drying oven at 35°C to -0.08Mpa to dry; The vacuum-dried powder is dispersed in 50 ml of a solution containing disodium hydrogen phosphate and sodium dihydrogen phosphate with a pH of 8.0 and an osmotic pressure of 320 mOsm / L to obtain a heterogeneous cross-linked sodium hyaluronate gel, in which disodium hydrogen phosphate : The weight-number ratio of sodium dihydrogen phosphate is 1:0.1.

Embodiment 3

[0032] Mix 18ml of isopropanol and 2ml of water to obtain an alcohol-water solution containing isopropanol with a volume fraction of 90%, take 10ml of the alcohol-water solution, add 1g of sodium hyaluronate with a molecular weight of 500,000, and stir magnetically to form a suspension; Add 0.01g EDC to the suspension, keep stirring, and react at 25°C for 90min; filter the reaction product with Buchner funnel, wash with 50ml ethanol for 3 times, collect the powder, and put it in a vacuum drying oven at 40°C to -0.08Mpa for drying ; Disperse the vacuum-dried powder in 50ml of pH 7.2, osmotic pressure of 300mOsm / L containing disodium hydrogen phosphate and sodium dihydrogen phosphate solution to obtain heterogeneous cross-linked sodium hyaluronate gel, wherein hydrogen phosphate The weight ratio of disodium: sodium dihydrogen phosphate is 1:0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Osmotic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com