Optical transmission receiver module and producing method, electronic device using with the same module

一种光接收元件、接收器的技术,应用在光学元件、电固体器件、光学等方向,能够解决光发射元件1103和光接收元件1105光学位置光学系统优化、损坏光纤分隔板等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

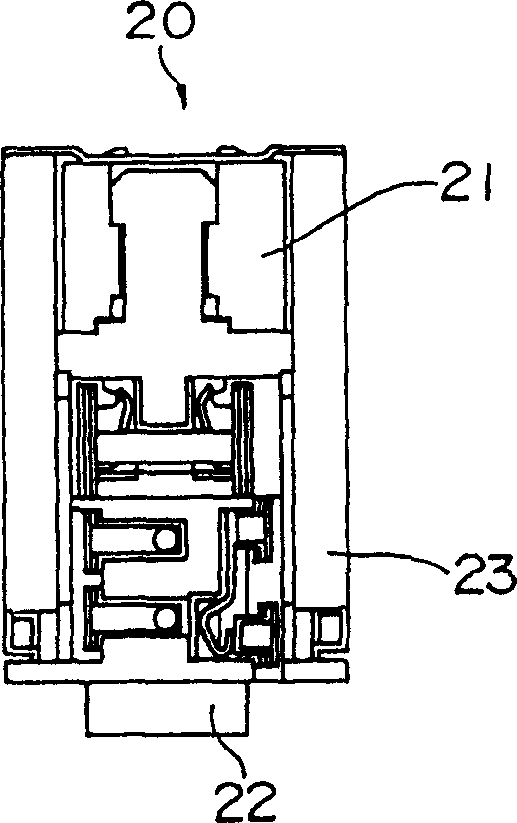

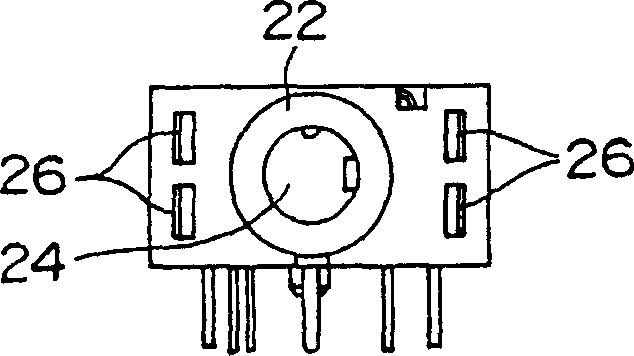

[0084] Next, the optical transceiver module and electronic equipment of the present invention will be described based on the embodiments of the present invention shown in the drawings.

[0085] In explaining the embodiments of the present invention, an outline of a method of manufacturing the optical transceiver module of the present invention will be first described, and then details of the configuration of the optical transceiver module and its manufacturing method will be described.

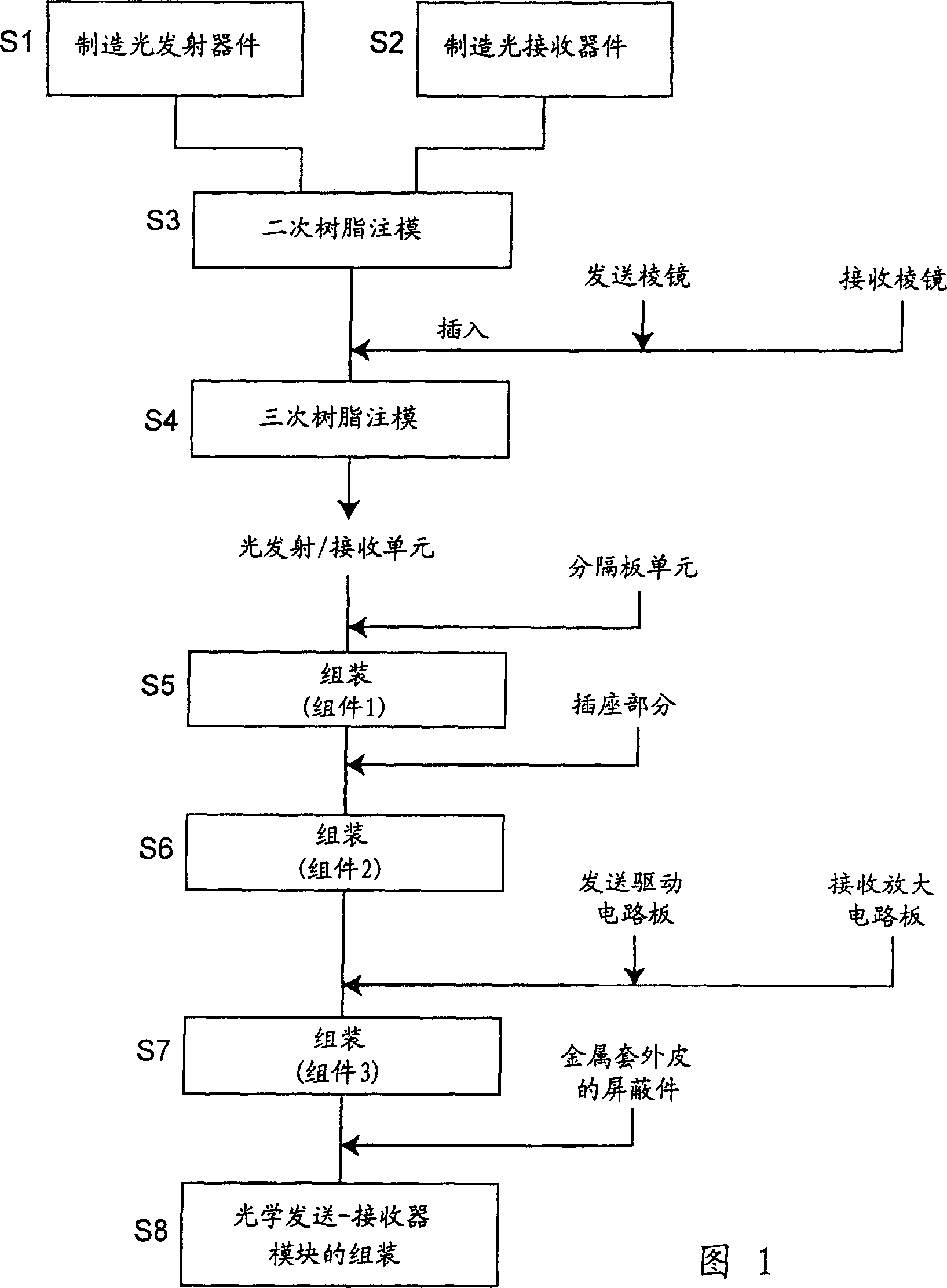

[0086] FIG. 1 is a flowchart showing a method of manufacturing the optical transceiver module of this embodiment. The optical transceiver module of this embodiment is manufactured according to the flowchart of FIG. 1 .

[0087] First, in step S1, a light-emitting device is manufactured by encapsulating a light-emitting element through transfer molding.

[0088] Next, in step S2, a light-receiving device is manufactured by encapsulating the light-receiving element by transfer molding.

[0089...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com