Fluorescent light luminotron and its manufacturing method

A light-emitting tube and fluorescent technology, which is applied in the manufacture of tube/lamp screen, discharge tube/lamp, cold cathode manufacture, etc. , easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

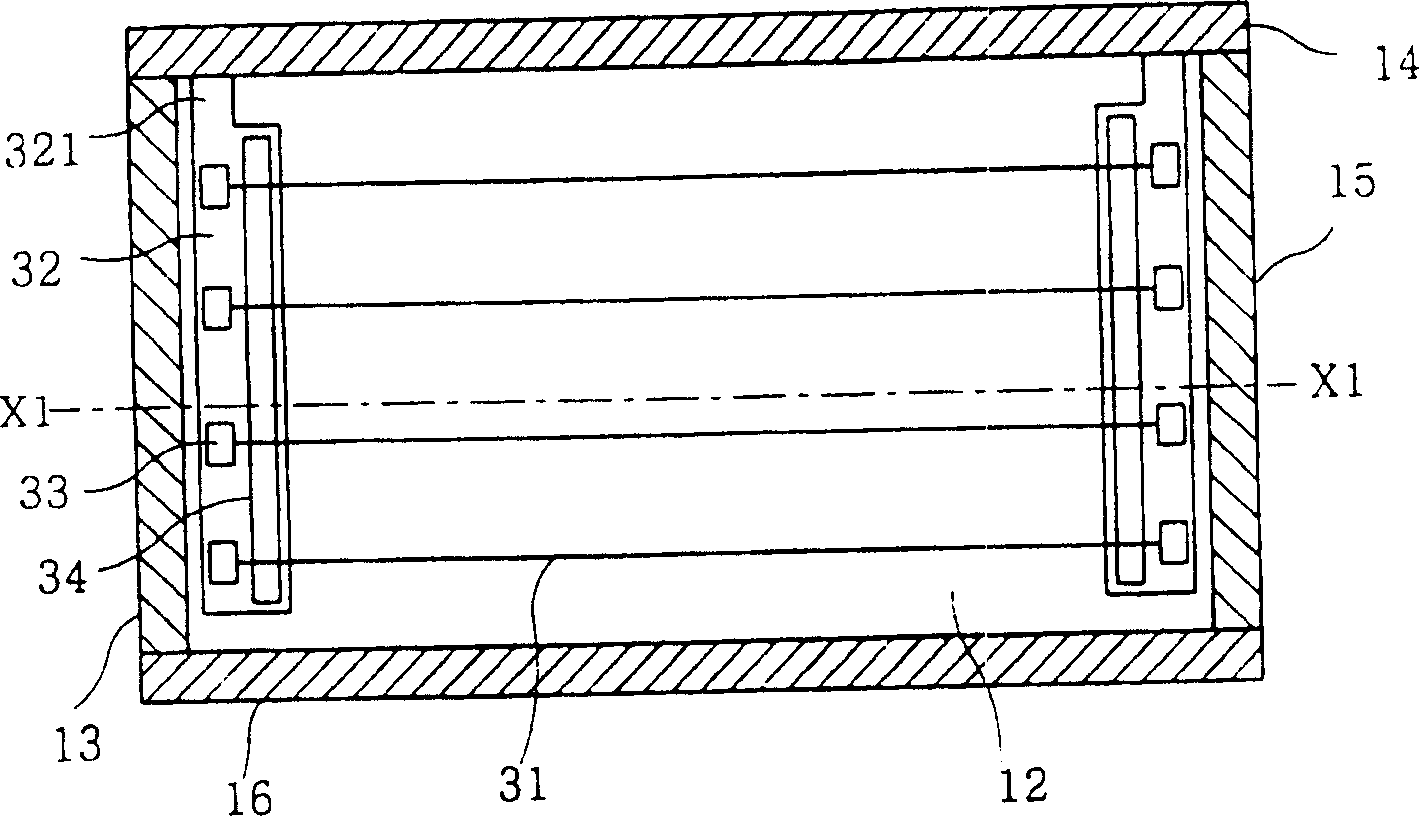

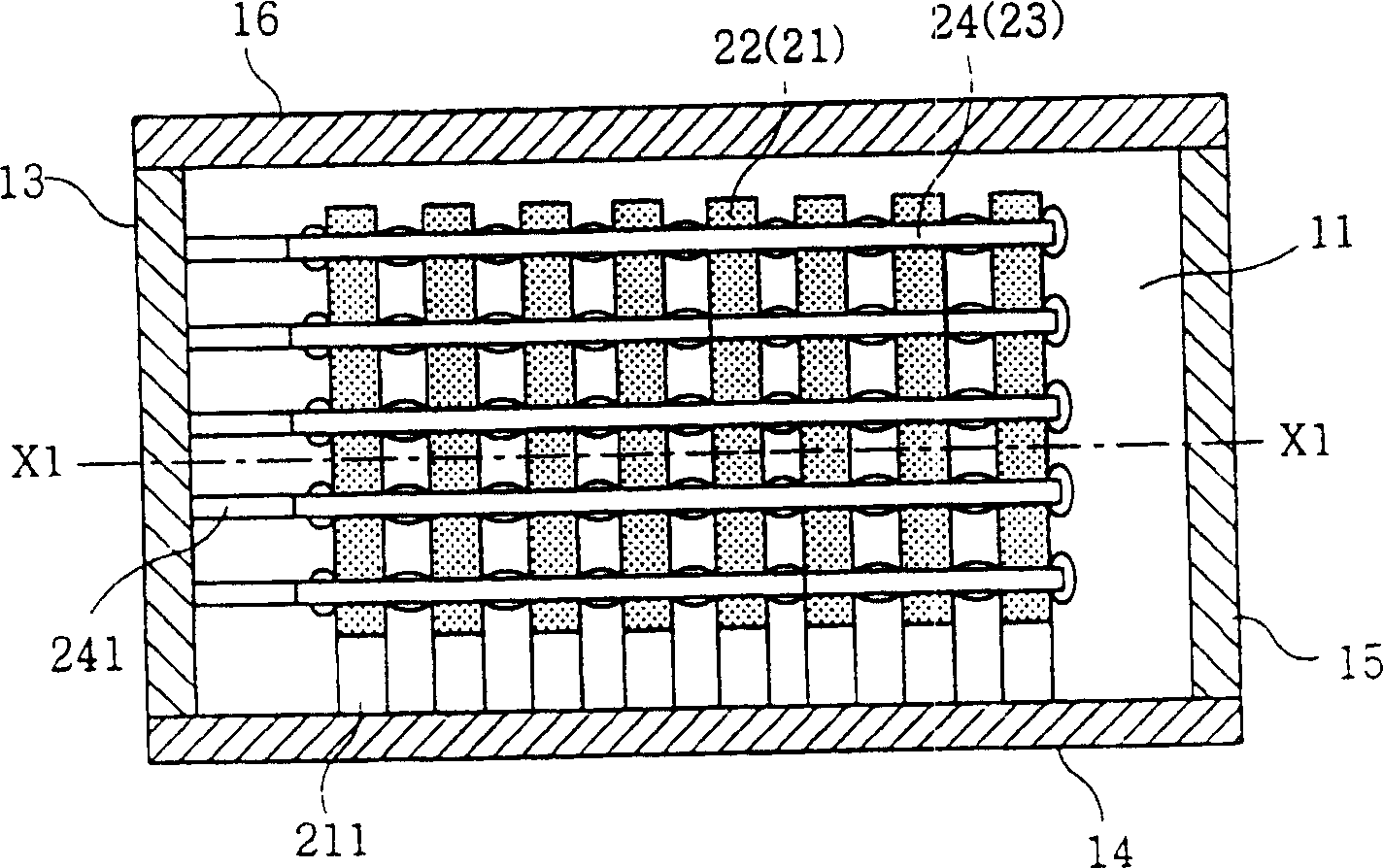

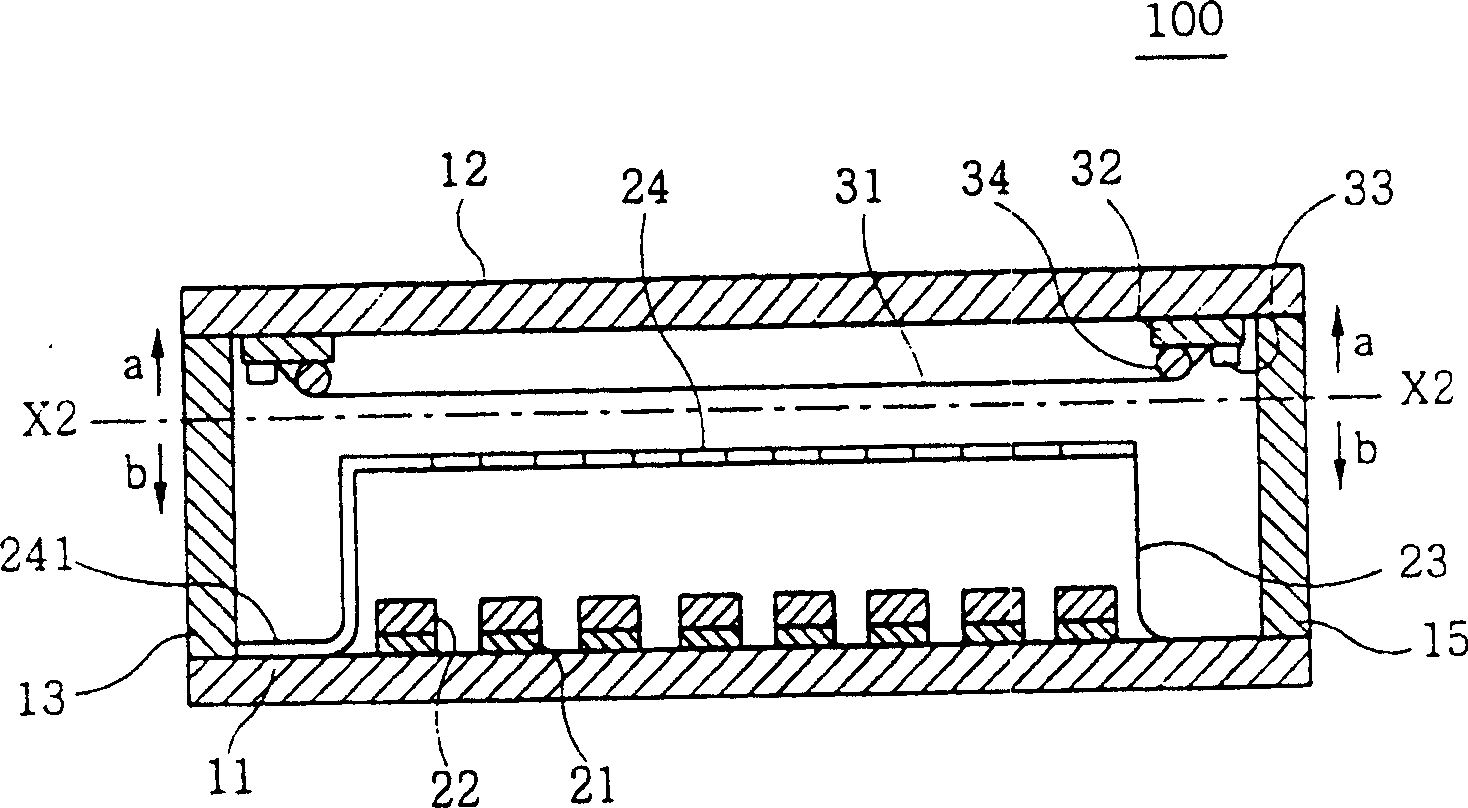

[0031] now refer to Figures 1A to 5 , a graphic fluorescent display tube and a manufacturing method thereof according to a preferred embodiment of the present invention are described in detail. Like numbers denote like parts in the drawings.

[0032] Figures 1A to 1C , Figure 2A and 2B are a plan view and a cross-sectional view, respectively, of a graphic fluorescent display tube 100 according to a first preferred embodiment of the present invention. Figure 1C is along Figure 1A and 1B The cross-sectional view made by the line "X1-X1"; Figure 1A and 1B are along Figure 1C A plan view taken along the line "X2-X2" in the direction of arrows "a" and "b"; Figure 2A show Figure 1B Partial enlarged view of Figure 2B shows along the Figure 2A The cross-sectional view made by the line "X3-X3" in;

[0033] The graphic fluorescent display tube 100 according to the first preferred embodiment of the present invention comprises side walls 13 to 16, an anode substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com