Process for the preparation of 2-ethylhexanal

A technology of ethylhexanal and ethylhexenal, which is applied in the field of preparation of 2-ethylhexanal, can solve the problems of increasing back-mixing and power consumption, high reaction temperature, and small raw material feeding space velocity, etc., and achieves reduction Condensation products, lowering the reaction temperature, prolonging the effect of using time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

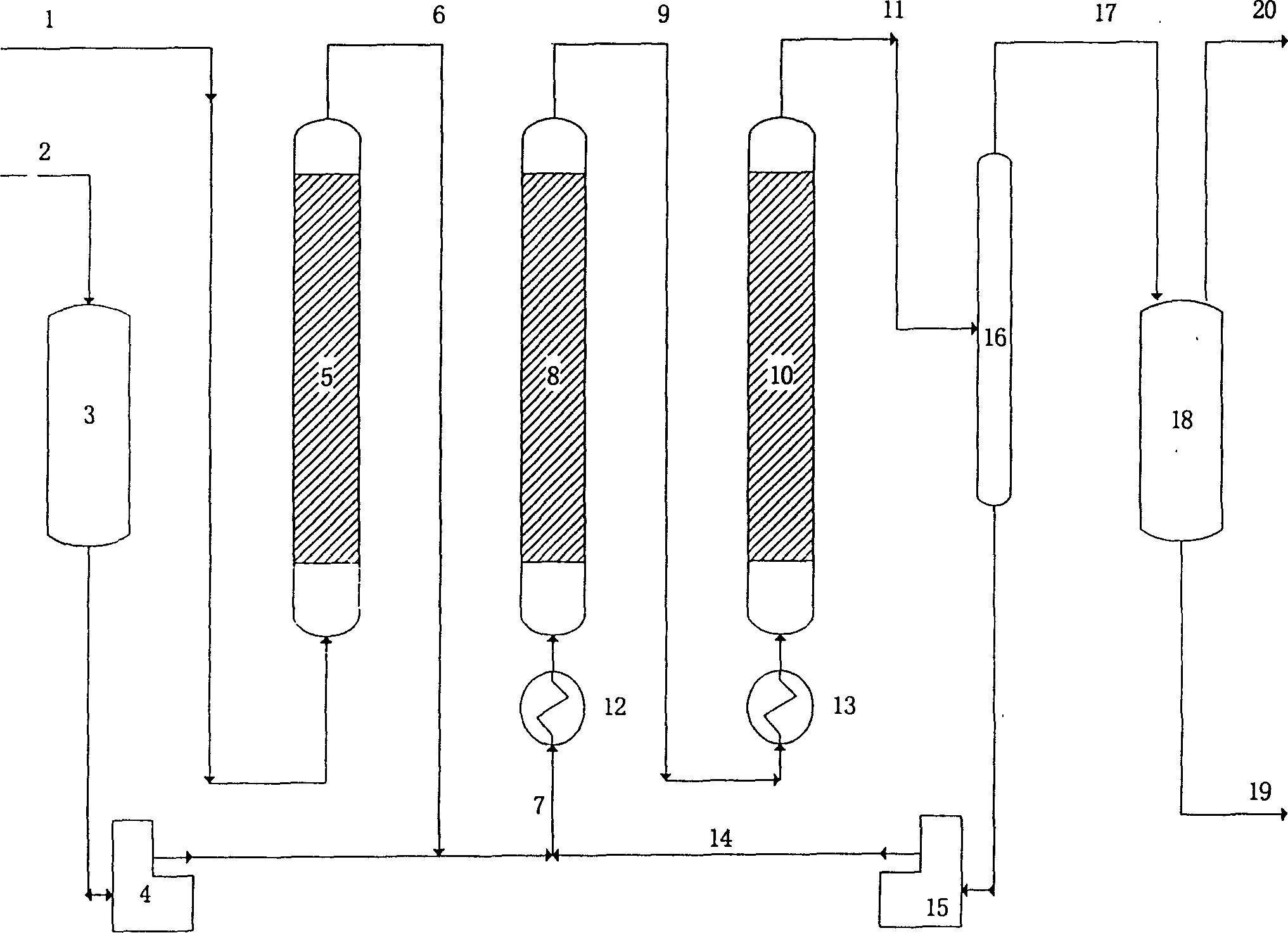

[0023] Test device such as figure 1 shown. A bubbling adiabatic fixed-bed reactor is adopted. The reactor is a Ф45×3.5 stainless steel tube with a height of 1 meter. There is a Ф3×1 thermocouple tube inside, and each is filled with 1 liter of catalyst. The catalyst is a palladium content of 0.22%, and the carrier γ-Al 2 o 3 .

[0024] Octenal is metered by the metering pump, mixed with the circulating product and hydrogen, and then enters the preheater to preheat to a certain temperature. The preheated mixture enters from the lower part of the reactor, and the gas-liquid mixture coming out of the first reactor is condensed After reaching a certain temperature, it enters from the lower part of the reactor. After the gas-liquid mixture from the second reactor enters the circulation metering tube, the liquid in the lower part passes through the circulation metering pump and mixes with octenal and enters the preheating of the first reactor. The gas-liquid mixture in the upper ...

Embodiment 2

[0030] The test device and the loaded catalyst are identical to those of Example 1, and the process conditions of Example 2 are as shown in Table 3.

[0031] reactor

[0032] The test results of Example 2 are shown in Table 4.

[0033] raw material

[0034] As can be seen from the analytical results of Example 1 and Example 2: the yield of 2-ethylhexanal is greater than 100%, and this is because in the process of hydrogenation, the condensation products of some three molecules of butyraldehyde can be untied to form Octenal and butyraldehyde, so that the yield of isooctaldehyde is higher than the theoretical calculation value.

Embodiment 3

[0036] The hydrogenation catalyst is 0.1% palladium, and the carrier is γ-Al 2 o 3 ,;

[0037] reactor

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com