Cobalt-based Fischer-Tropsch synthesis heavy hydrocarbon catalyst as well as preparation method and application thereof

A technology of Tropsch synthesis and catalyst, applied in the field of cobalt-based Fischer-Tropsch synthesis of heavy hydrocarbon catalysts and its preparation, can solve the problems of expensive carrier, undisclosed heavy hydrocarbon selectivity, etc. The effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

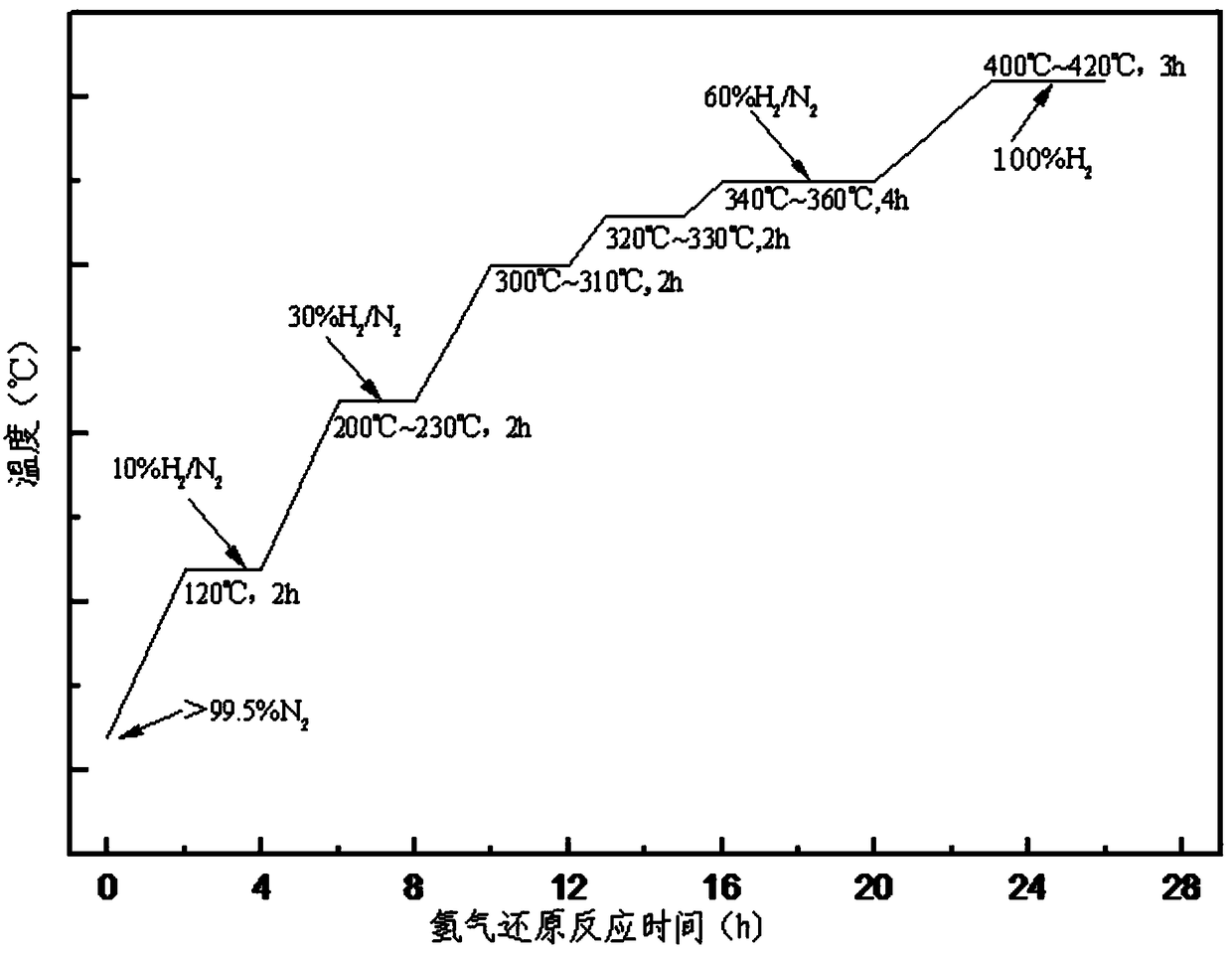

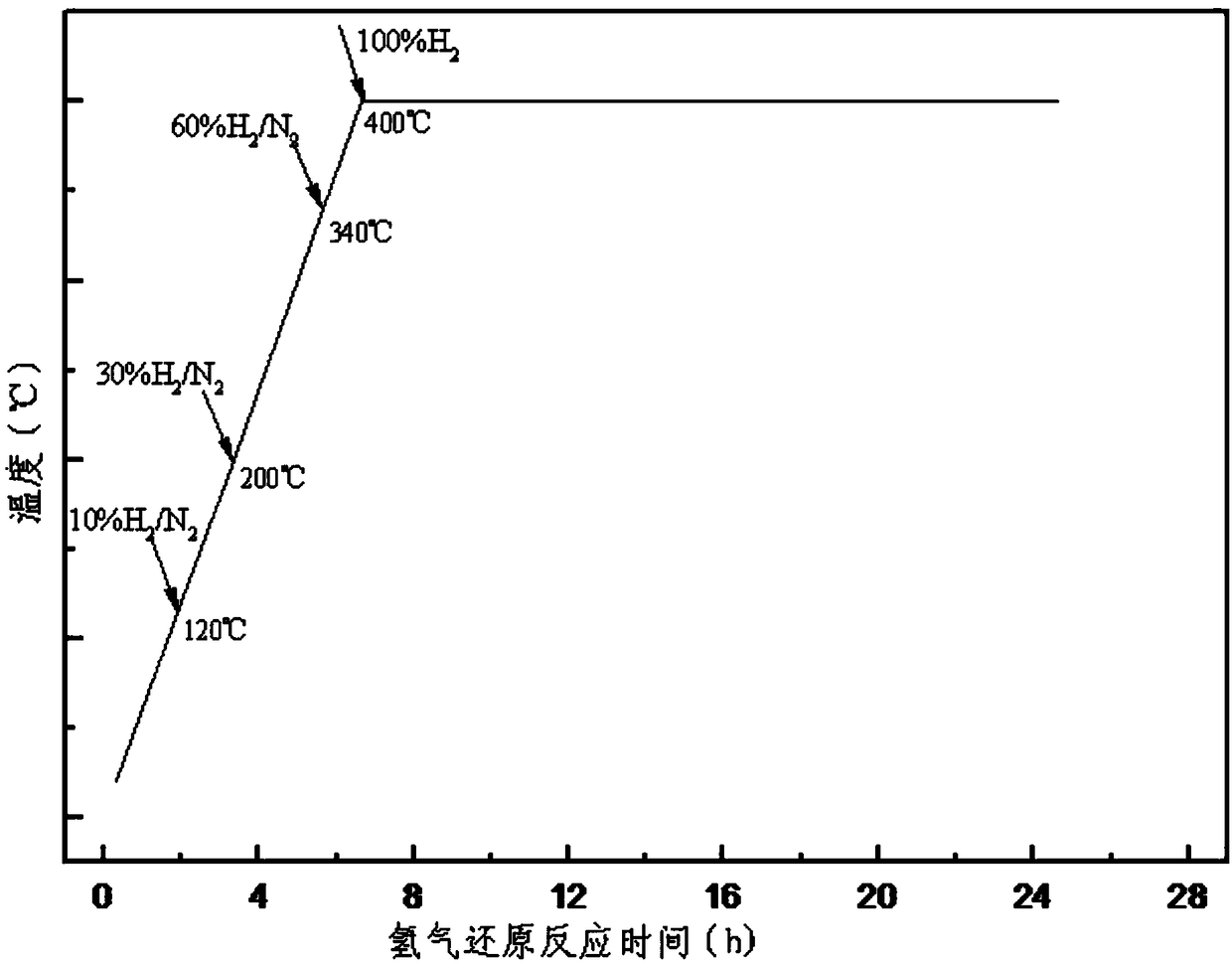

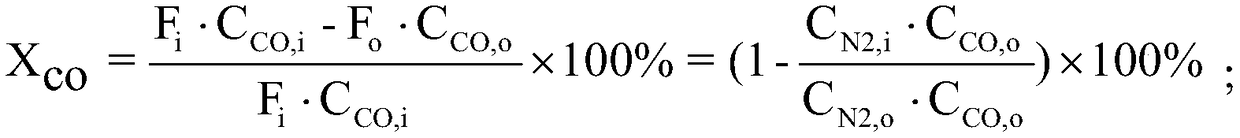

Method used

Image

Examples

Embodiment 1

[0040] The catalyst of this embodiment is made up of the composition of following mass percentage: 15% cobalt, 0.1% rhenium, all the other are gamma-Al 2 o 3 carrier; the γ-Al 2 o 3 The pore size of the carrier is 14nm and the specific surface area is 280m 2 / g, the pore volume is 0.80mL / g.

[0041] The preparation method of the catalyst of the present embodiment comprises the following steps:

[0042] Step 1. Add 0.254mol cobalt nitrate hexahydrate and 0.127mol citric acid into deionized water to prepare a mixed solution, then add 1.4mL of perrhenic acid whose rhenium concentration is 71.4g / L, and dilute to 130mL with deionized water, Obtain an impregnation solution;

[0043] Step 2: Spray 65mL impregnating solution evenly onto 84.9g of γ-Al 2 o 3 On the carrier, impregnate equal volume at room temperature for 3.5h, and then dry at 70°C for 6h;

[0044] Step 3, the dried γ-Al in step 2 2 o 3 The carrier was calcined at 210°C for 1 hour, then heated to 300°C for 5 ho...

Embodiment 2

[0047] The catalyst of this embodiment is made up of the composition of following mass percentage: 18% cobalt, 0.3% rhenium, all the other are gamma-Al 2 o 3 carrier; the γ-Al 2 o 3 The pore size of the carrier is 12nm and the specific surface area is 300m 2 / g, the pore volume is 0.65mL / g.

[0048] The preparation method of the catalyst of the present embodiment comprises the following steps:

[0049] Step 1. Add 0.305 mol of cobalt acetate and 0.183 mol of citric acid into deionized water to prepare a mixed solution, then add 4.2 mL of perrhenic acid with a rhenium concentration of 71.4 g / L, and dilute to 120 mL with deionized water to obtain impregnation liquid;

[0050] Step 2: Spray 60mL impregnating solution evenly onto 81.7g of γ-Al 2 o 3 On the carrier, impregnate equal volume at room temperature for 2 hours, and then dry at 60°C for 8 hours;

[0051] Step 3, the dried γ-Al in step 2 2 o 3 The carrier was calcined at 190°C for 3 hours, then heated to 330°C fo...

Embodiment 3

[0054] The catalyst of this embodiment is made up of the composition of following mass percentage: 20% cobalt, 0.2% rhenium, all the other are gamma-Al 2 o 3 carrier; the γ-Al 2 o 3 The pore size of the carrier is 23nm and the specific surface area is 185m 2 / g, the pore volume is 1.00mL / g.

[0055] The preparation method of the catalyst of the present embodiment comprises the following steps:

[0056] Step 1. Add 0.339mol of cobalt acetate tetrahydrate and 0.271mol of ammonium ethylenediaminetetraacetate into deionized water to prepare a mixed solution, then add 4mL of ammonium perrhenate solution with rhenium concentration of 50g / L, and use deionized water Dilute to 140mL to obtain impregnation solution;

[0057] Step 2: Evenly spray 70mL impregnating liquid onto 79.8g of γ-Al 2 o 3 On the carrier, impregnate equal volume at room temperature for 5.5h, and then dry at 80°C for 5h;

[0058] Step 3, the dried γ-Al in step 2 2 o 3 The carrier is calcined at 200°C for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com