Sulfur-tolerant catalyst for synthesized gas methanation and preparation method and application of sulfur-tolerant catalyst

A catalyst and gas methane technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, gas fuels, etc., can solve the problems of small specific surface of cerium oxide, complex preparation process, sublimation of active components, etc., and achieve active site density Large, high content, the effect of increasing the effective content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

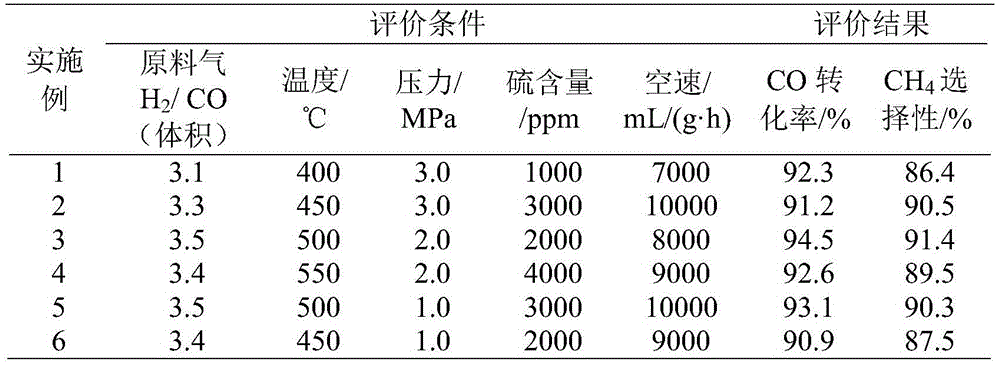

Examples

Embodiment 1

[0021] (1) Preparation of Mo-Al alloy powder: mix 5.8g of molybdenum powder with particle size of 3-6μm, 4.1g of aluminum powder of 4-6μm and 0.1g of iron metal powder of 4-6μm; Molten, and with 1*10 6 k / s was cooled to room temperature under nitrogen protection, and ground to 90 mesh for later use;

[0022] (2) The vulcanization process of the catalyst: the alloy powder prepared in (1) has a volume composition of 3% H 2 / 97%H 2 Vulcanized at 350°C for 5 hours in an atmosphere of S;

[0023] (3) Preparation of sulfur-resistant catalyst: mix the catalyst precursor prepared in (2) with solid sodium hydroxide, the mass ratio of sodium hydroxide to alloy powder is 1:1; distilled water whose volume is 3 times that of alloy powder is dropped dropwise Add dropwise to the mixture and stir magnetically at 80 / min; at the same time, place it in a water bath, control the temperature of the water bath to 0°C; after the addition, the suspension is ultrasonicated at 50kHz, 60°C for 30min,...

Embodiment 2

[0026] (1) Preparation of Mo-Al alloy powder: mix 5.6g of molybdenum powder with particle size of 3-6μm, 4.3g of aluminum powder of 4-6μm and 0.1g of nickel metal powder of 6-8μm; Molten, and with 1*10 6 k / s was cooled to room temperature under nitrogen protection, and ground to 100 mesh for later use;

[0027] (2) The vulcanization process of the catalyst: the alloy powder prepared in (1) has a volume composition of 5% H 2 / 95%H 2 Sulfurization at 450°C for 5 hours in an atmosphere of S;

[0028] (3) Preparation of sulfur-resistant catalyst: the catalyst precursor prepared in (2) is mixed with solid sodium hydroxide and the mass ratio of sodium hydroxide to alloy powder is 1.1:1; the volume is distilled water 3 times that of alloy powder Add dropwise to the mixture and stir magnetically at 90 / min; at the same time, place it in a water bath and control the temperature of the water bath to 3°C; after the addition, the suspension is ultrasonicated at 60kHz and 50°C for 30min ...

Embodiment 3

[0031](1) Preparation of Mo-Al alloy powder: Mix 5.4g of molybdenum powder with particle size of 6-9μm, 4.3g of aluminum powder of 8-10μm and 0.3g of cerium metal powder of 6-8μm; Melted, and with 1.2*10 6 k / s was cooled to room temperature under nitrogen protection, and ground to 100 mesh for later use;

[0032] (2) The vulcanization process of the catalyst: the alloy powder prepared in (1) has a volume composition of 7% H 2 / 93%H 2 Vulcanized at 450°C for 3 hours in an atmosphere of S;

[0033] (3) Preparation of sulfur-resistant catalyst: the catalyst precursor prepared in (2) is mixed with solid sodium hydroxide and the mass ratio of sodium hydroxide to alloy powder is 1.2:1; the volume is distilled water 4 times that of alloy powder Add dropwise to the mixture and stir magnetically at 100r / min; at the same time, place it in a water bath and control the temperature of the water bath to 5°C; after the addition, the suspension is ultrasonicated for 40min at 70kHz and 50°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com