Polycarbonyl polyimide organic electrode material, preparation method and application thereof

A carbonyl polyimide and organic electrode technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor rate performance, low conductivity, high solubility, etc., and achieve improved cycle stability, easy availability of raw materials, The effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1: Under inert (argon) conditions, 3mmol NTCDA and 3mmol maleamide diamide were successively added to 30mL m-cresol under mechanical stirring (400 rev / s), followed by 2mL isoquinoline, and the temperature was raised to Reflux reaction 20h obtains polycarbonyl polyimide (PMN) crude product mixed solution;

[0037] Step 2: discharge the polycarbonyl polyimide (PMN) crude product mixed solution obtained in step 1 into methanol, then suction filter the obtained mixed solution, and wash the filter residue with acetone and N-methylpyrrolidone (NMP) respectively After three times, the obtained solid was vacuum-dried to obtain polycarbonyl polyimide (PMN), the structural formula is as follows, and the yield was 68%.

[0038]

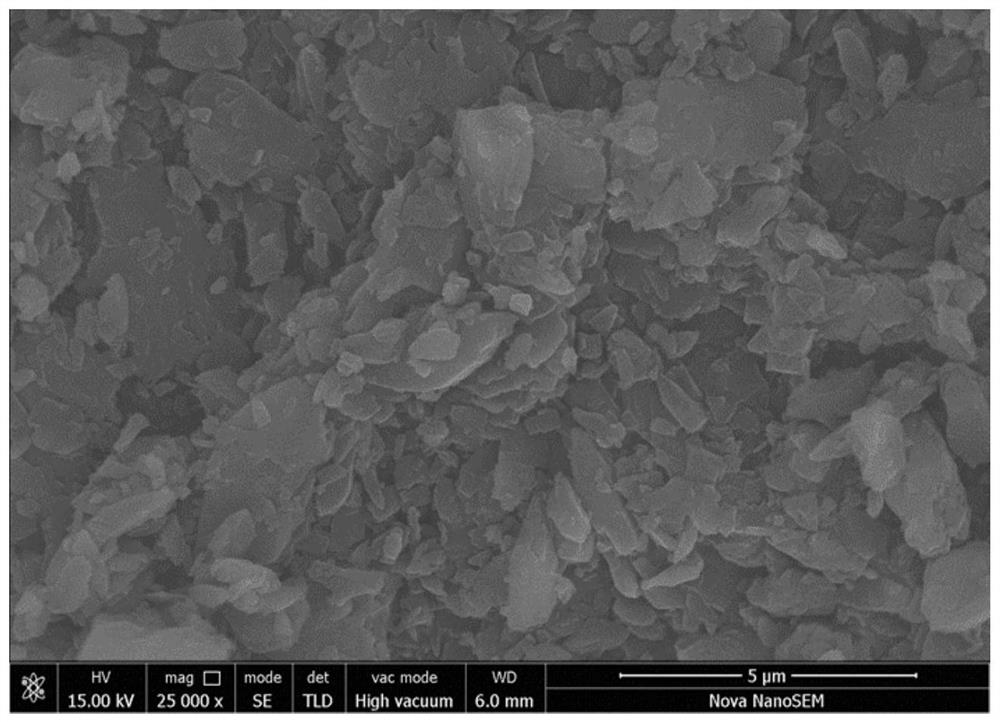

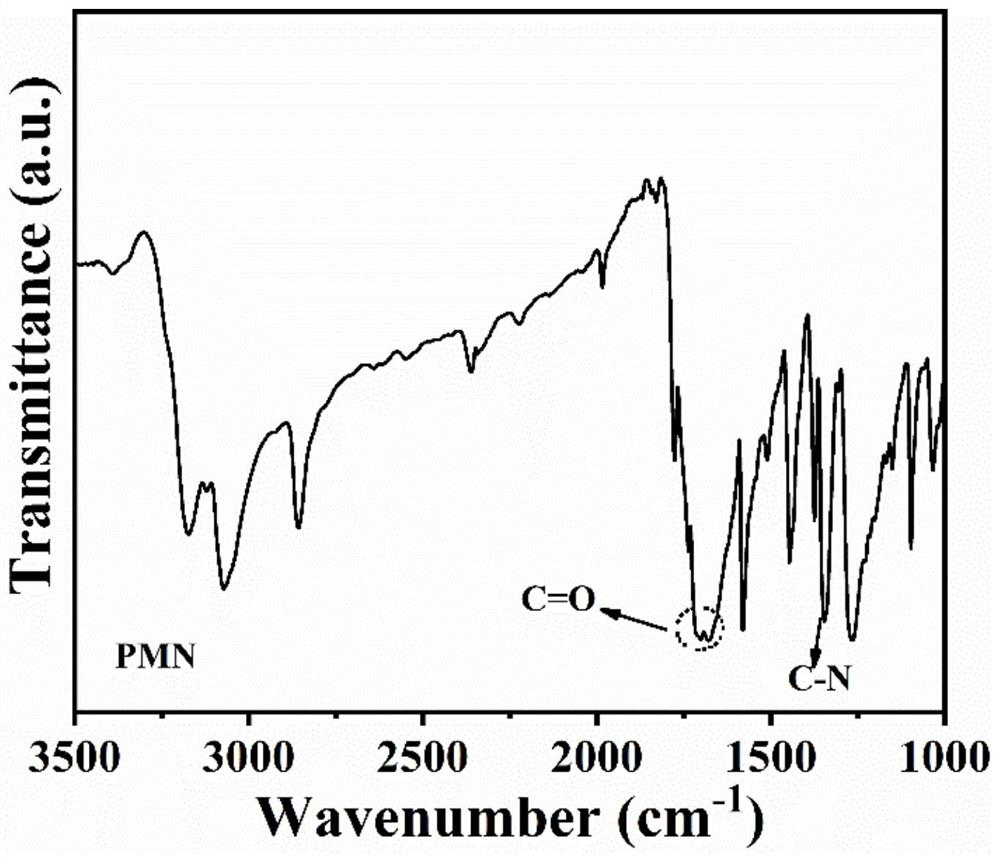

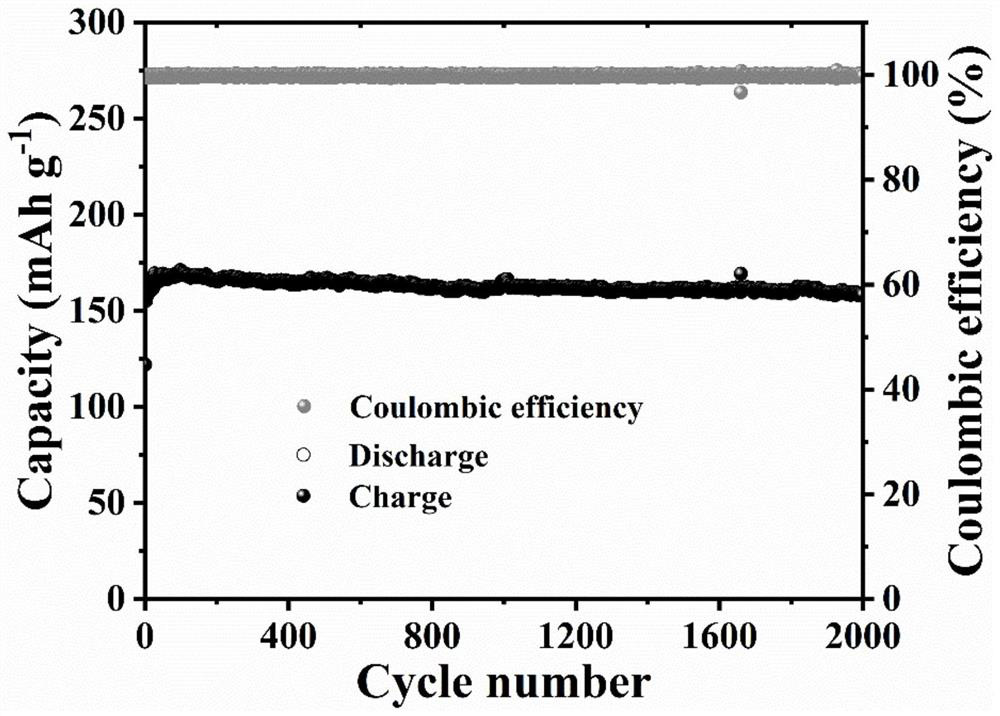

[0039] Through the electron microscope test ( figure 1 ) found that the microscopic morphology of PMN is a flake-like solid with a length of 1 to 3 microns, and the infrared test ( figure 2 ) shows that there are two carbonyl peaks in different...

Embodiment 2

[0043] Under inert (argon) conditions, 3mmol NTCDA and 3mmol azodicarbonamide were successively added to 30mL m-cresol under mechanical stirring (400 rev / s), followed by 2mL isoquinoline, heated to reflux for 20h to obtain Polycarbonyl polyimide (PAN) crude product mixed solution;

[0044] Step 2: Discharge the polycarbonyl polyimide (PAN) crude product mixed solution obtained in step 1 in methanol, then suction filter the obtained mixed solution, and wash the filter residue with acetone and N-methylpyrrolidone (NMP) respectively After three times, the obtained solid was vacuum-dried to obtain polycarbonyl polyimide (PAN), with a yield of 74%, and the structural formula was as follows.

[0045]

[0046] Through the electron microscope test ( Figure 4 ) found that the microscopic morphology of PAN is a flake-like solid with a length of 1-5 microns, and the infrared test ( Figure 5 ) shows that there are two carbonyl peaks in different chemical environments and the generati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com