Automatic aligning method for optical waveguide device and optical fibre array

An optical fiber array, automatic alignment technology, applied in the coupling of optical waveguides, instruments, non-electric variable control and other directions, can solve problems such as difficulty and long time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

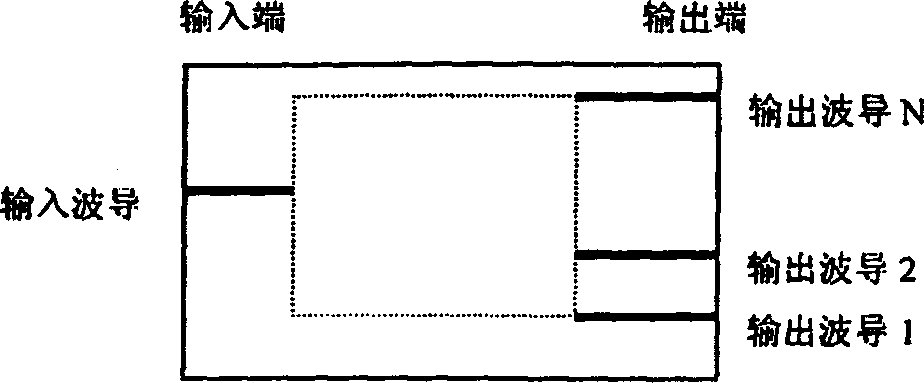

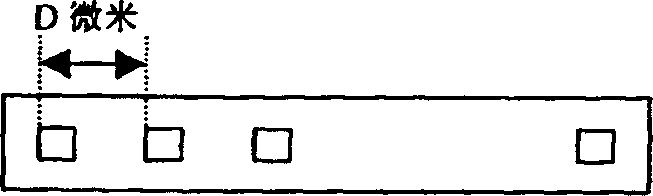

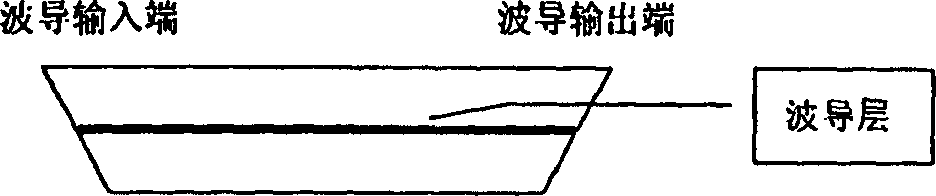

[0023] Figure 7 shows the schematic diagram of the automatic alignment system of the waveguide device and the optical fiber array, using an industrial computer with an image acquisition card and a data acquisition card, two electric six-dimensional fine-tuning frames and an electric control module for the fine-tuning frames, and three electric charge The coupling device CCD and its adapter lens, the upper end of the six-dimensional fine-tuning frame 2-1 on the left is fixed with an optical fiber array 1-1 used as an input end, and the upper end of the six-dimensional fine-tuning frame 2-2 on the right is fixed with an optical fiber array 1-2 used as an output end , the output fibers of the fiber array 1-1 and 1-2 are facing the waveguide device, the fiber input end of the fiber array 1-1 is connected to the broadband light source, and the fiber input end of the fiber array 1-2 is connected to each channel of the power meter , the position of the waveguide device remains unchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com