Oil fume removal equipment

A technology of oil fume device and range hood, which is applied in the direction of oil fume removal, household heating, heating methods, etc., can solve the problems of outdoor environmental pollution, large air resistance, and motor consumption, and achieve good oil fume removal effect, small air resistance, The effect of less power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

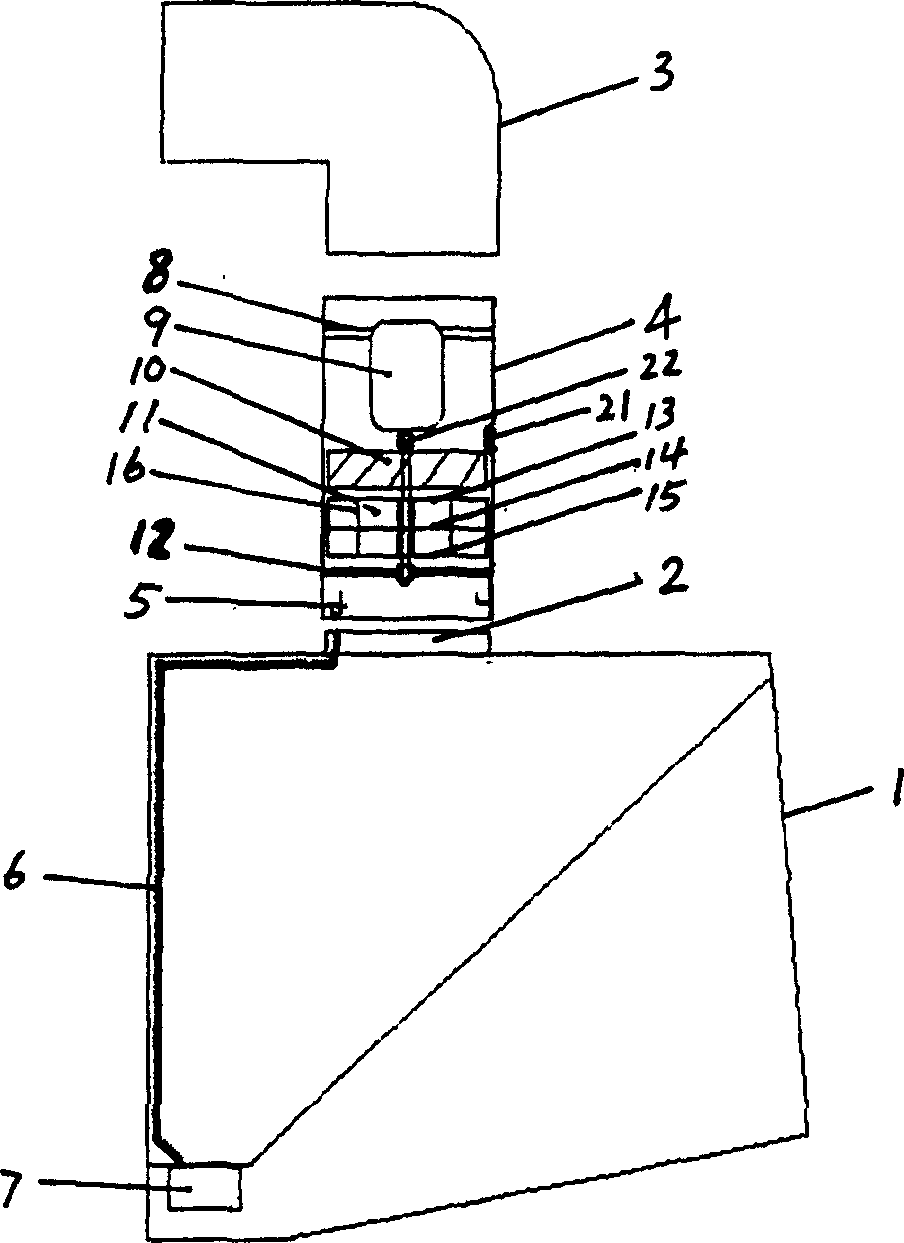

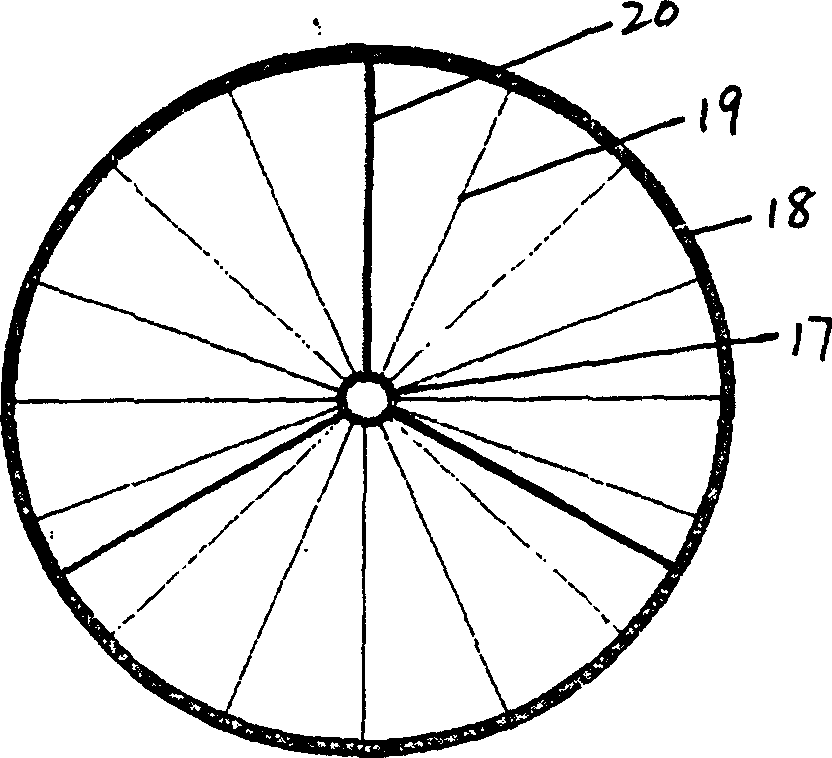

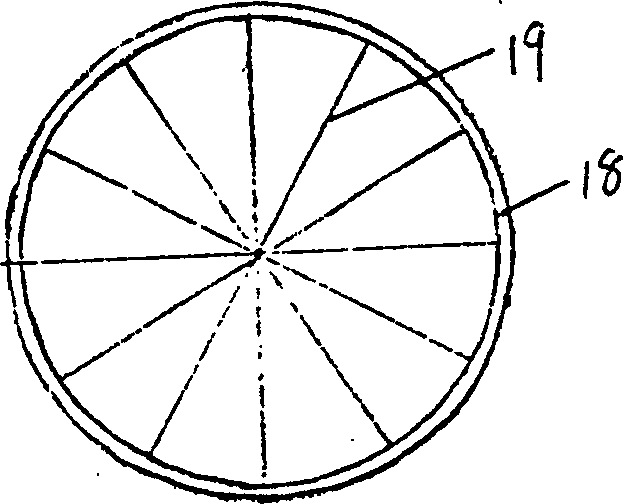

[0014] see figure 1 , figure 2 A section of oil collecting sleeve 4 is set between the air outlet 2 and the exhaust pipe 3 of the existing mainstream range hood 1 in the market. The air outlet 2 of the range hood is connected, and an oil return hole is provided at the bottom of the oil collection groove ring 5 and is communicated with the oil collection cup 7 of the range hood through a conduit 6 . The inner wall of the oil-collecting casing 4 is fixedly connected with an outlet end bracket 8, on which an auxiliary motor 9 is installed, and the output end of the auxiliary motor 9 is connected to the wind wheel 10 or the rotating shaft of the filter element 11 through a movable transmission, and the other end of the rotating shaft of the filter element 11 is connected through a bearing. On the inlet end bracket 12 fixedly connected with the inner wall of the oil collecting casing 4 . The filter core 11 is preferably composed of 2-3 layers of radial spoke wire sheets, figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com