Assembly device for assembling substrates and assembling line with said assembling apparatus

A technology for assembling equipment and substrates, applied in the direction of electrical components, electrical components, etc., can solve the problems of enlarged movement path of assembly head and decreased assembly efficiency, and achieve the effect of easy casting technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

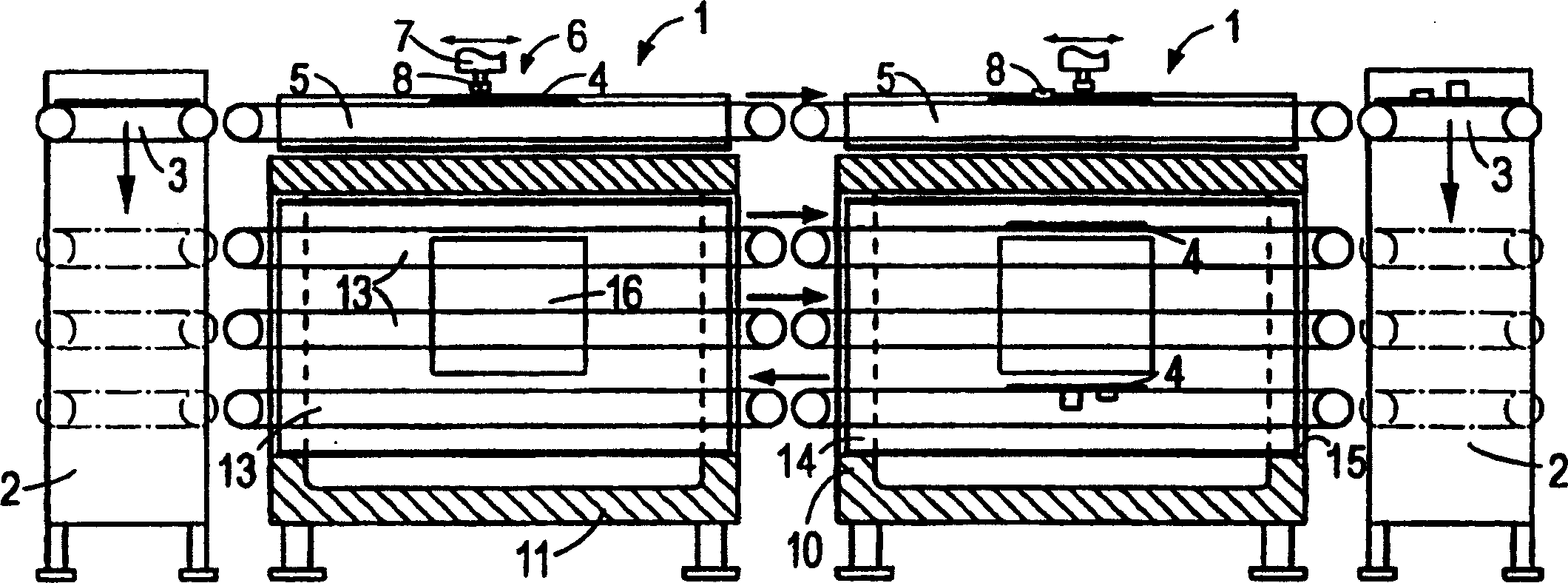

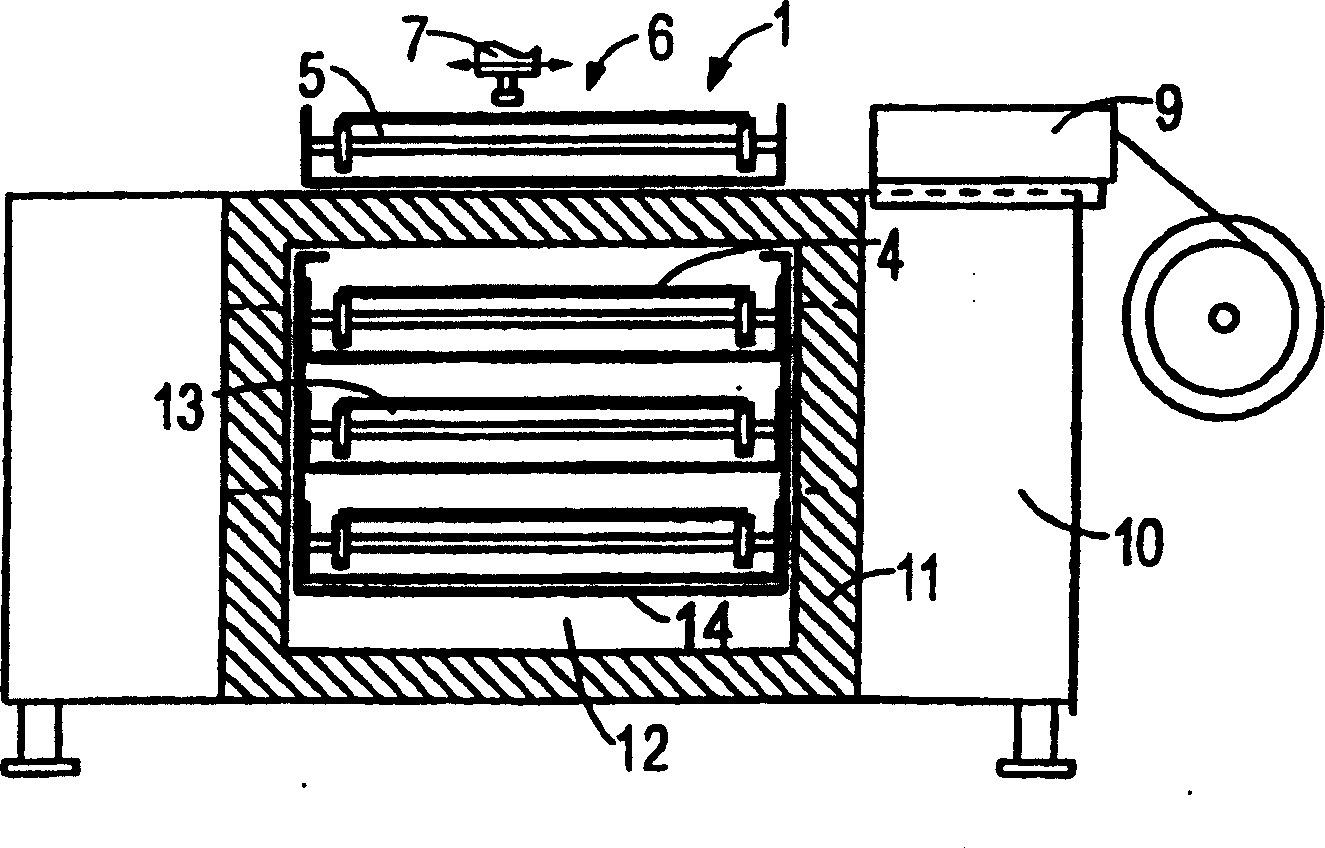

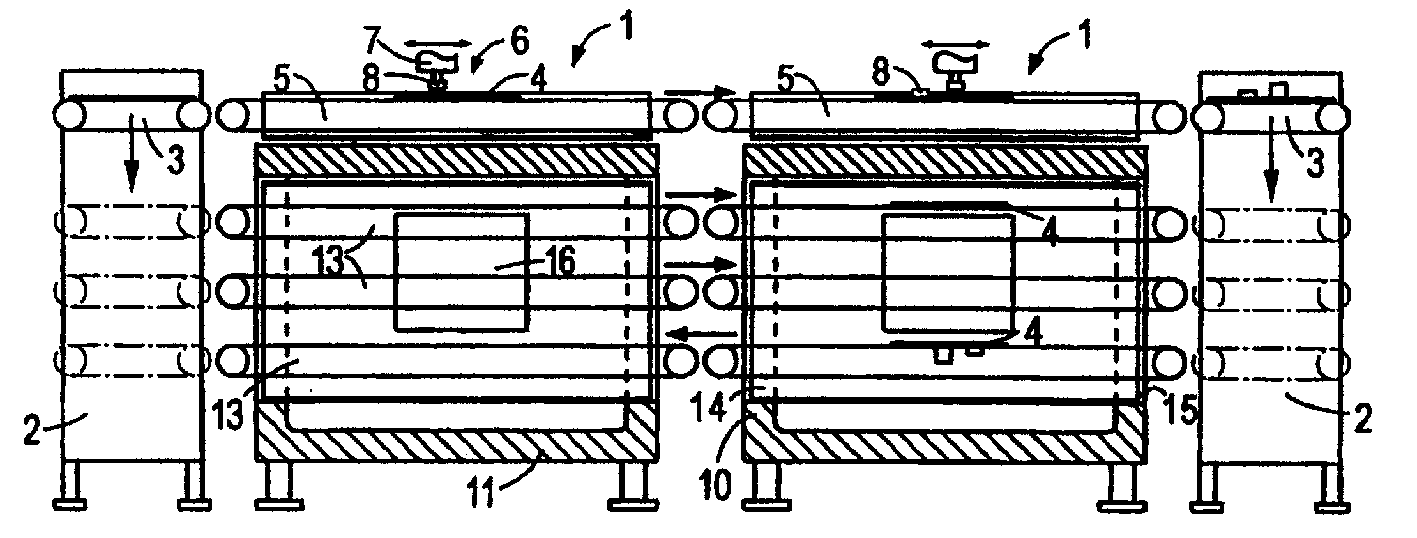

[0020] according to figure 1 and 2 , on both sides of the two following assembly devices 1 there is a transfer device 2 with a transfer mechanism 3 for the substrate 4 that is movable along its height. The assembly device 1 has a transport section 5 on an upper assembly plane, in the middle region of which an assembly point 6 is arranged, above which an assembly head 7 is movable in two coordinate directions. The assembly head 7 is used for taking electrical components 8 from a supply device 9 and placing them on the substrate 4 .

[0021] The assembly device 1 has a frame 10, which is located below the transport section 5 and is a frame member 11 with a rectangular tubular cross-sectional structure. This frame part 11 , which is open at both ends, forms a free space 12 with installation locations for conveyor sections 13 which are located vertically below the transport section 5 and run parallel thereto. The transfer mechanism 3 is movable in the vertical direction between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com