Absorbent products

A technology for absorbent products and absorbent components, applied in the field of absorbent products, which can solve the problems that the top layer is easy to stick to the wearer, does not mention, forms gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) Form the preparation of the first layer material

[0069] Heat-bondable sheath-core composite fiber (this composite fiber is made up of polyethylene terephthalate core and polyethylene sheath, the weight ratio of core / sheath is 5 / 5, fineness is 2.2dtex, fiber Length is 51 millimeters (NBF-SH, can obtain from Daiwabo Co., Ltd.)) carded into a web, and heat treatment at 120 ℃, to prepare have basis weight be 15g / m 2 of non-woven fabrics.

[0070] (2) Form the preparation of the second layer material

[0071] With self crimping fiber (it is the heat-shrinkable sheath-core type combination fiber that is made up of ethylene-propylene random copolymer (EP) core and polypropylene (PP) sheath, has fineness 2.2dtex and shrinkage initiation temperature Ts is 90°C, (available from Daiwabo Co., Ltd.)) and carded into a web. The obtained nonwoven fabric had a basis weight of 35 g / m 2 .

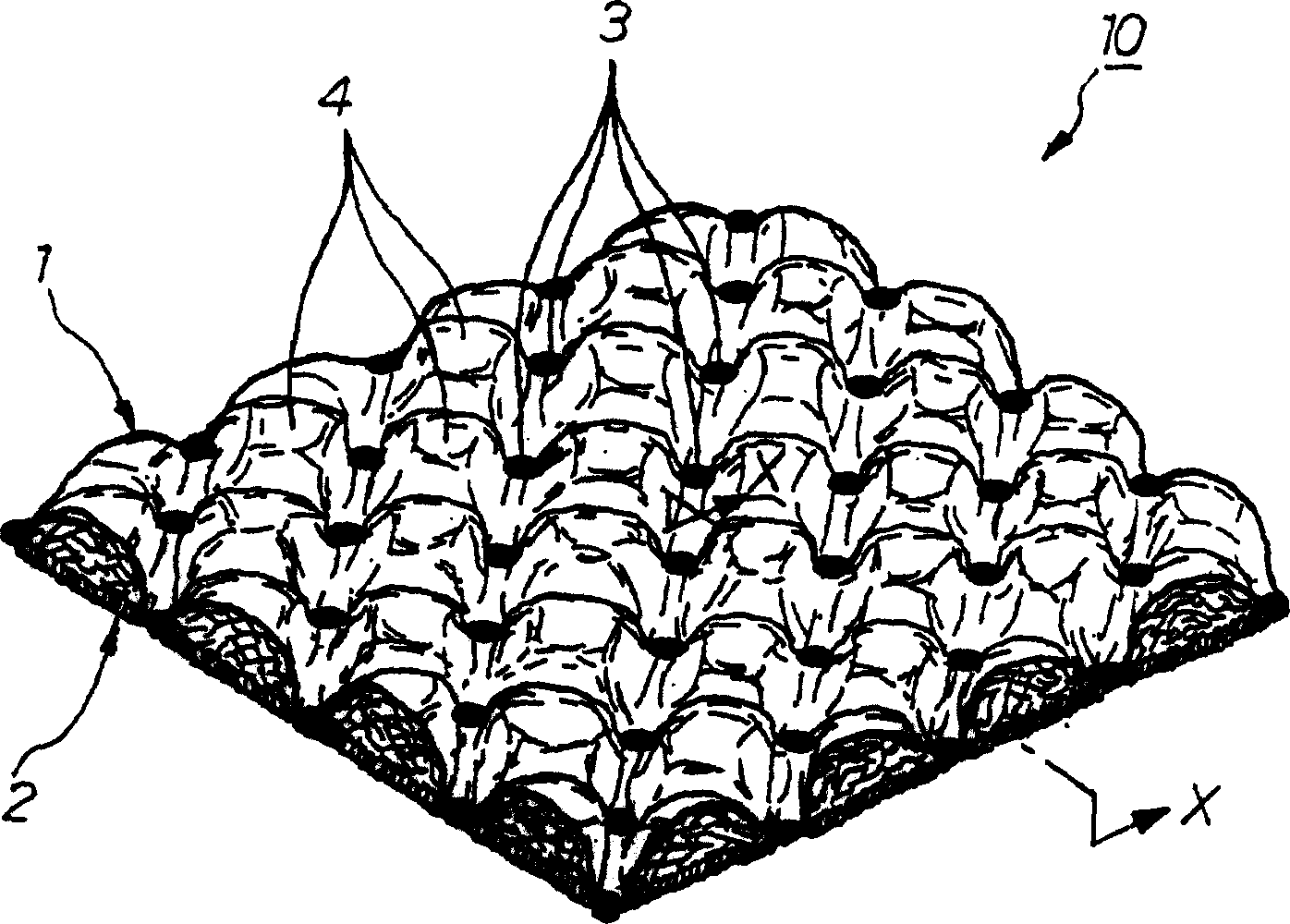

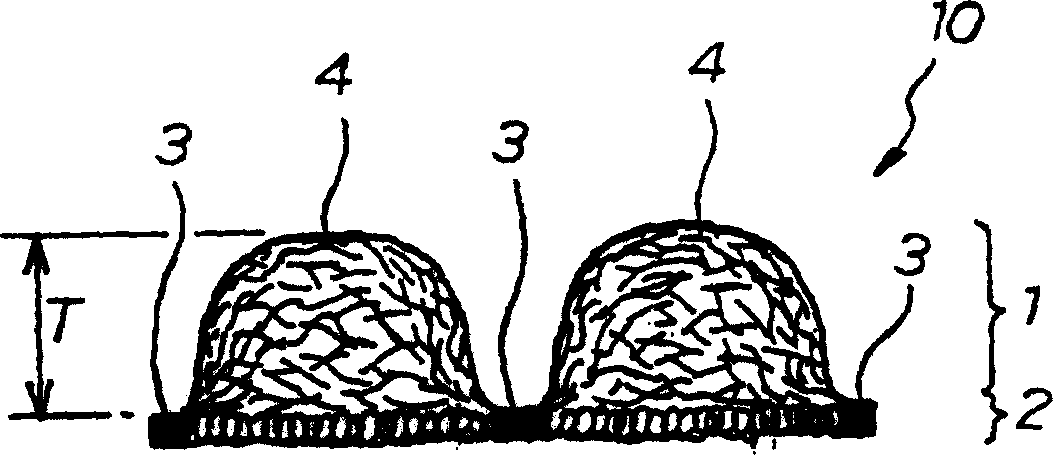

[0072] (3) Preparation of bulky flakes

[0073] The nonwoven fabrics prepared in (1) a...

Embodiment 2

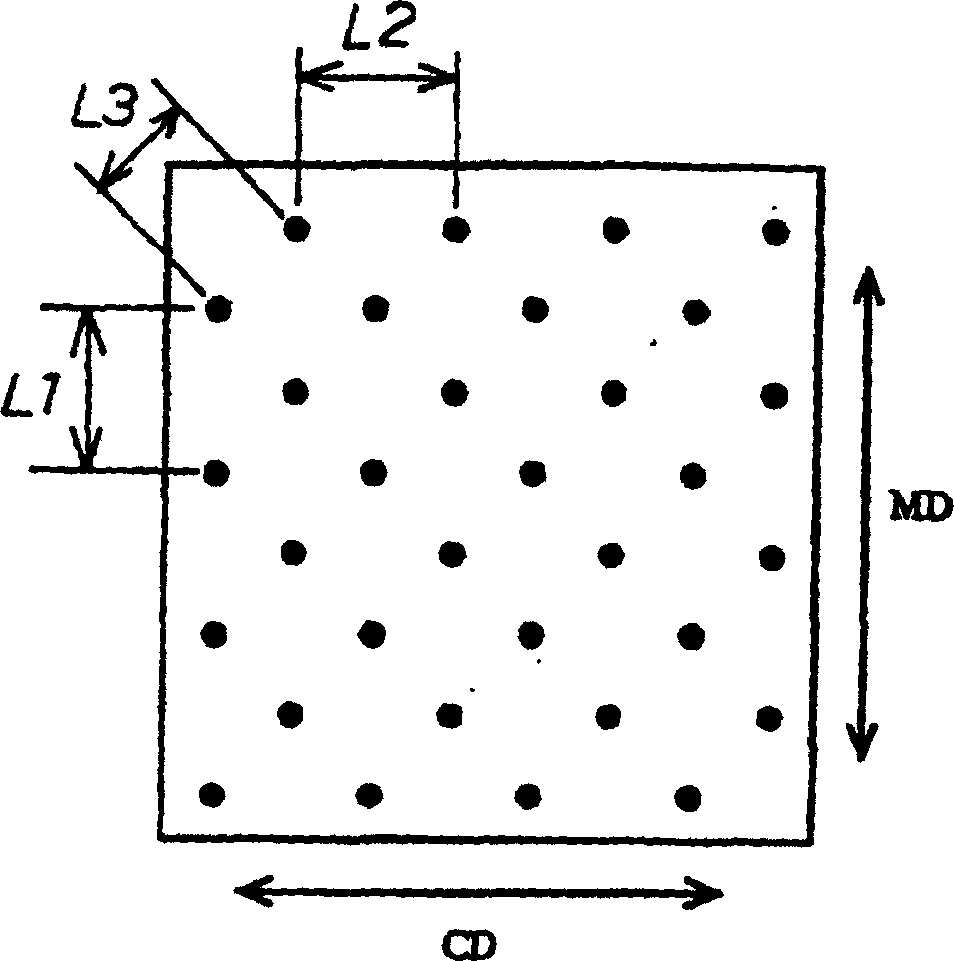

[0080] The bulky sheet prepared in Example 1 was cut into rectangles, 80 mm wide in CD and 230 mm long in MD. Separately prepare two 60 mm wide water-repellent spunbonded nonwoven fabrics having a basis weight of 18 g / m 2 , consisting of a core-sheath composite fiber comprising a polyethylene terephthalate core and a polyethylene jacket. Each strip of spunbonded nonwoven fabric was folded in two along its longitudinal direction to prepare a pair of 30 mm wide strips 14 (folded) (see Fig. 9(a) and Fig. 9(b)).

[0081] The bulky thin slice 10 was stretched 10% in the MD. The mountain-folded side of the folded nonwoven fabric strip 14 was bonded to each longitudinal side of the stretched lofty sheet 10 with a 10 mm coverage using hot melt adhesive 15 . The resulting composite sheet had a 60 mm wide portion of the lofty sheet 10 and a 30 mm wide double folded spunbond nonwoven fabric 14 on both sides of the lofted sheet.

[0082] The composite sheet was placed on the same absor...

Embodiment 3

[0086] A sanitary napkin was prepared in the same manner as in Example 2, except that the composite sheet was fixed in the MD with its bulky sheet partially stretched by 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com