Method of reinforcing soft base using large diameter thin wall pipe pole composite ground

A thin-walled pipe pile and composite foundation technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of small bearing capacity of single pile, few construction teams, small diameter of pile body, etc. Fast speed and low penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but it does not constitute any limitation to the present invention.

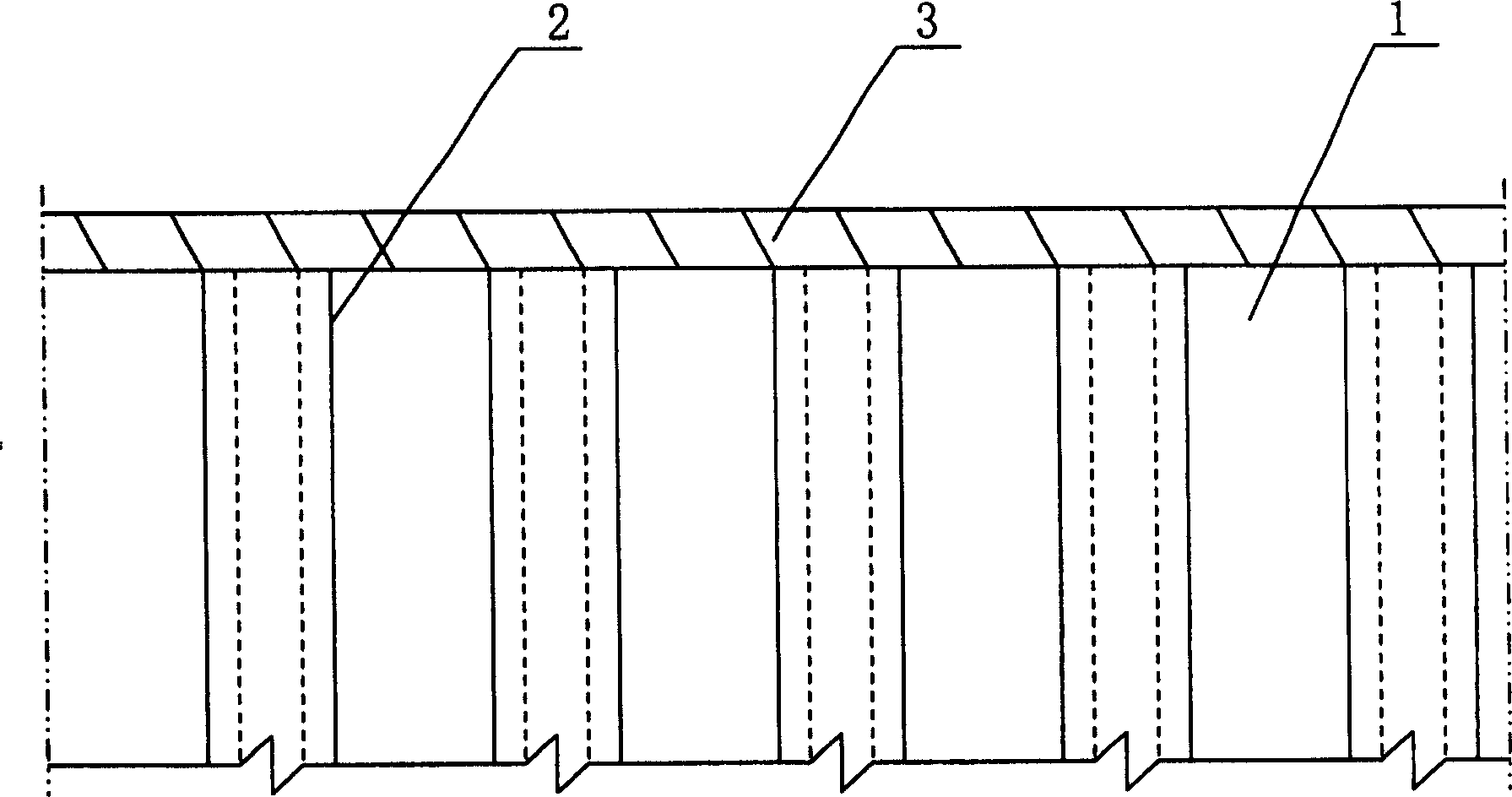

[0020] Such as figure 1 As shown, the method for reinforcing soft ground with large-diameter thin-walled pipe pile composite foundation of the present invention, its technological process is: large-diameter thin-walled pipe pile prefabrication → pipe pile construction → cushion layer is set, and now each process is described as follows:

[0021] Prefabrication of large-diameter thin-walled pipe piles: First, large-diameter thin-walled pipe piles are prefabricated in the factory. Compared with ordinary pipe piles, this kind of large-diameter thin-walled pipe piles has the characteristics of lower concrete strength, smaller wall thickness / diameter, and less reinforcement; The diameter of the pipe pile is usually 600-1000mm, and the wall thickness is 50-100mm.

[0022] Pipe pile construction: use constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com