Method for preparing composite polycarboxylate superplasticizer from straws

A technology for compounding polycarboxylic acid and water reducing agent, which is applied in the field of preparing compound polycarboxylic acid water reducing agent by using straw, can solve the problems of increased alkali content of admixtures, adverse effects on concrete mechanical properties, shortened service life of buildings, and the like. The effect of improving water reduction rate and concrete strength, improving concrete workability, and increasing concrete slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

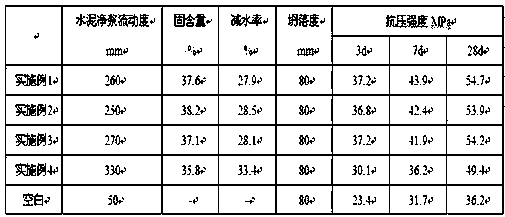

Examples

Embodiment 1

[0019] A kind of method utilizing straw to prepare composite polycarboxylate water reducing agent, comprises the following steps:

[0020] Step 1: collect the straw, dry it and crush it, mix the dry powder with dilute hydrochloric acid solution, heat it to 100°C for 3 hours, let it cool, filter to remove the acid solution, and rinse with water to get the wet powder;

[0021] Step 2, mix the wet powder in step 1 with isopropanol solution of sodium hydroxide, keep warm at 20°C for 2 hours, add sodium sulfite and 1,3-propyl sultone, react with ultrasound for 1 hour, filter and rinse with absolute ethanol , to obtain modified cellulose;

[0022] Step 3, mix isobutylene alcohol polyoxyethylene ether and sodium methacrylate sulfonate, heat to 70°C, add ammonium persulfate and acrylic acid dropwise, keep warm for 3 hours, adjust the pH to 6 after cooling, and add the modified fiber in step 2 element, stirred to obtain a mixed solution;

[0023] Step 4, add formaldehyde to the mixed...

Embodiment 2

[0031] A kind of method utilizing straw to prepare composite polycarboxylate water reducing agent, comprises the following steps:

[0032] Step 1: collect the straw, dry it and crush it, mix the dry powder with dilute hydrochloric acid solution, heat it to 105°C for 3 hours, let it cool, filter to remove the acid solution, rinse with water to get the wet powder;

[0033] Step 2, mix the wet powder of step 1 with the isopropanol solution of sodium hydroxide, keep warm at 25°C for 1h, add sodium sulfite and 1,3-propyl sultone, react with ultrasound for 1h, filter and rinse with absolute ethanol , to obtain modified cellulose;

[0034] Step 3, mix isobutylene alcohol polyoxyethylene ether and sodium methacrylate sulfonate, heat to 80°C, add ammonium persulfate and acrylic acid dropwise, keep warm for 3 hours, adjust the pH to 7 after cooling, and add the modified fiber in step 2 element, stirred to obtain a mixed solution;

[0035] Step 4, add formaldehyde to the mixed solution...

Embodiment 3

[0043] A kind of method utilizing straw to prepare composite polycarboxylate water reducing agent, comprises the following steps:

[0044] Step 1: collect the straw, dry it and crush it, mix the dry powder with dilute hydrochloric acid solution, heat it to 110°C for 2 hours, let it cool, filter to remove the acid solution, rinse with water to get the wet powder;

[0045] Step 2, mix the wet powder of step 1 with the isopropanol solution of sodium hydroxide, keep warm at 30°C for 1 hour, add sodium sulfite and 1,3-propyl sultone, react with ultrasound for 1 hour, filter and rinse with absolute ethanol , to obtain modified cellulose;

[0046] Step 3, mix isobutylene alcohol polyoxyethylene ether and sodium methacrylate sulfonate, heat to 90°C, add ammonium persulfate and acrylic acid dropwise, keep the temperature for 2 hours, adjust the pH to 8 after cooling, and add the modified fiber in step 2 element, stirred to obtain a mixed solution;

[0047] Step 4, add formaldehyde to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com