Highway concrete admixture and preparation method thereof

A concrete admixture and road technology, applied in the field of concrete, can solve the problems of increased slump loss of concrete mixture, reduced performance of water reducer, weakened dispersion performance of water reducer, etc., to reduce subsequent filtration steps, The effect of increased fluidity and improved performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Including the following materials in parts by weight: 60 parts of industrial naphthalene, 40 parts of entrainer, 54 parts of concentrated sulfuric acid, 39 parts of formaldehyde, 5 parts of triethanolamine, 8 parts of ethylene glycol, 15 parts of antiwear agent, 3 parts of sodium nitrate .

[0028] The entrainer is 1,2-dichloroethane.

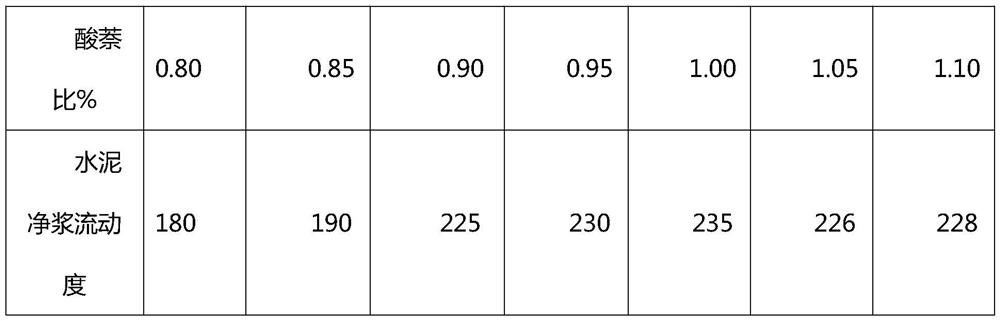

[0029] The weight ratio of concentrated sulfuric acid to industrial naphthalene is 0.9-1.1, and the optimal ratio is 0.9:1.

[0030] The optimum weight ratio of formaldehyde and industrial naphthalene is 0.65:1.

[0031] The optimum weight ratio of the industrial naphthalene to 1,2-dichloroethane is 1.5:1.

[0032] A neutralizing agent is included, and the neutralizing agent is selected from sodium hydroxide or lime.

[0033] A preparation method for road concrete admixture, comprising the steps of:

[0034] Weigh 60 parts of industrial naphthalene, 5 parts of triethanolamine, 8 parts of ethylene glycol, 15 parts of anti-wear agent a...

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1 is that the parts by weight of each component are different, wherein 90 parts of industrial naphthalene, 60 parts of entrainer, 81 parts of vitriol oil, 59 parts of formaldehyde, 15 parts of triethanolamine, 16 parts of ethylene glycol , 25 parts of anti-wear agent, 19 parts of sodium nitrate.

Embodiment 3

[0050] The difference between embodiment 3 and embodiment 1 is that the parts by weight of each component are different, wherein 70 parts of industrial naphthalene, 50 parts of entrainer, 70 parts of vitriol oil, 46 parts of formaldehyde, 10 parts of triethanolamine, 12 parts of ethylene glycol , 20 parts of anti-wear agent, 10 parts of sodium nitrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com