Laundry detergent compositions comprising zwitterionic polyamines and mid-chain branched surfactants

A surfactant and zwitterion technology, applied in the direction of surface active detergent composition, detergent composition, organic detergent composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

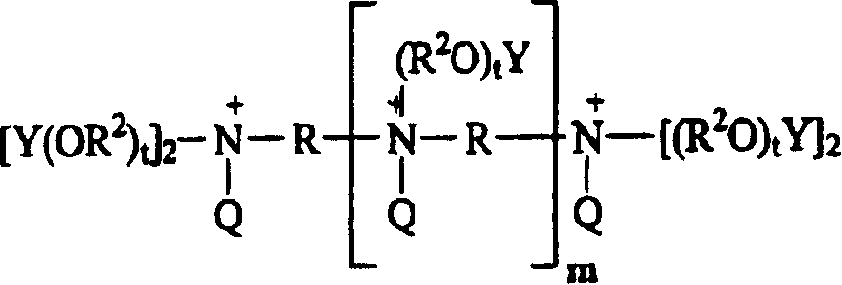

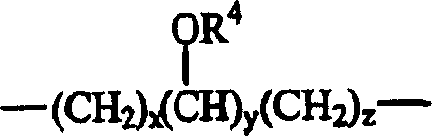

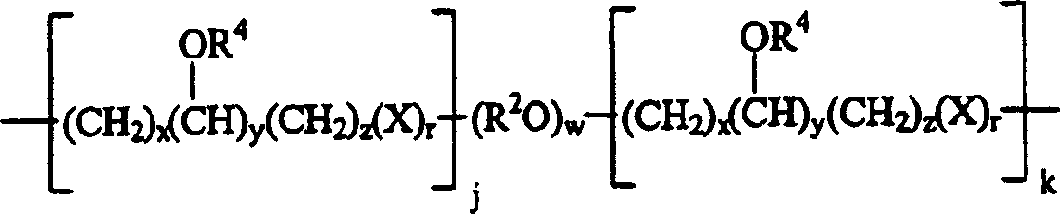

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0214] Preparation of 4,9-dioxa-1,12-dodecanediamine, ethoxylated to average E20 / NH,

[0215] Quaternized to 90% and sulfated to 90%.

[0216] 4,9-dioxa-1,12-dodecanediamine was ethoxylated to an average of 20 ethoxylates / backbone NH unit . Ethoxygenation was carried out in a 2 gallon stirred stainless steel autoclave equipped with means for temperature measurement and control, pressure measurement, vacuum evacuation and inert gas purge, sampler and means for introducing ethylene oxide as a liquid Kylation reaction. An approximately 20 lb net weight cylinder of ethylene oxide was installed to pump the ethylene oxide as a liquid into the autoclave, where the cylinder was placed on a balance so that the cylinder's weight change could be monitored. A 200 g portion of 4,9-dioxa-1,12-dodecanediamine ("DODD", m.w. 204.32, 97%, 0.95 mol, 1.9 mol N, 3.8 mol ethoxylated NH) was added into the autoclave. The autoclave was then sealed and purged of air (by applying...

Embodiment 2

[0223] Ethoxylated to average E20 / NH, quaternized to 90%, and sulfated to 35% bis

[0224] Preparation of (hexamethylene)triamine.

[0225] Ethoxylation of bis(hexamethylene)triamine Ethoxygenation was carried out in a 2 gallon stirred stainless steel autoclave equipped with means for temperature measurement and control, pressure measurement, vacuum evacuation and inert gas purge, sampler and means for introducing ethylene oxide as a liquid Kylation reaction. An approximately 20 lb net weight cylinder of ethylene oxide was installed to pump the ethylene oxide as a liquid into the autoclave, where the cylinder was placed on a balance so that the cylinder's weight change could be monitored.

[0226] A 200 g portion of bis(hexamethylene)triamine (BHMT) (M.W. 215.39, high purity 0.93 mol, 2.8 mol N, 4.65 mol ethoxylated (NH) sites) was charged to the autoclave. The autoclave was then sealed and purged of air (by applying vacuum to minus 28"Hg, followed by pre...

Embodiment 3

[0233] Ethoxylated to average E20 / NH, quaternized to 90%, and sulphated to 90%

[0234] Preparation of 4,7,10-trioxa-1,13-tridecanediamine.

[0235] Ethoxylation of 4,7,10-trioxa-1,13-tridecanediamine : Ethanol was carried out in a 2 gallon stirred stainless steel autoclave equipped with means for temperature measurement and control, pressure measurement, vacuum evacuation and inert gas purge, sampler and means for introducing ethylene oxide as a liquid. Oxylation reaction. A cylinder of approximately 20 pounds net weight of ethylene oxide was installed to pump the ethylene oxide as a liquid into the autoclave and was placed on a balance so that the cylinder's weight change could be monitored. A 200 g portion of 4,7,10-trioxa-1,13-tridecanediamine (Mw 220.31 Daltons, 97% 0.9 mol, 1.8 mol N, 3.6 mol ethoxylated (NH) sites ) into the autoclave. The autoclave was then sealed and purged of air (by applying vacuum to minus 28"Hg, followed by pressurization to 250 psi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com