Long target-distance nozzle for high pressure washing

A technology of high-pressure water and target distance, which is applied in the direction of cleaning methods and utensils, spraying devices, spraying devices, etc., can solve the problems of long target distance nozzles without cleaning effect, decreased jet energy of nozzles, and poor cleaning effect, etc., and achieve simple structure , extended target distance, wide coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

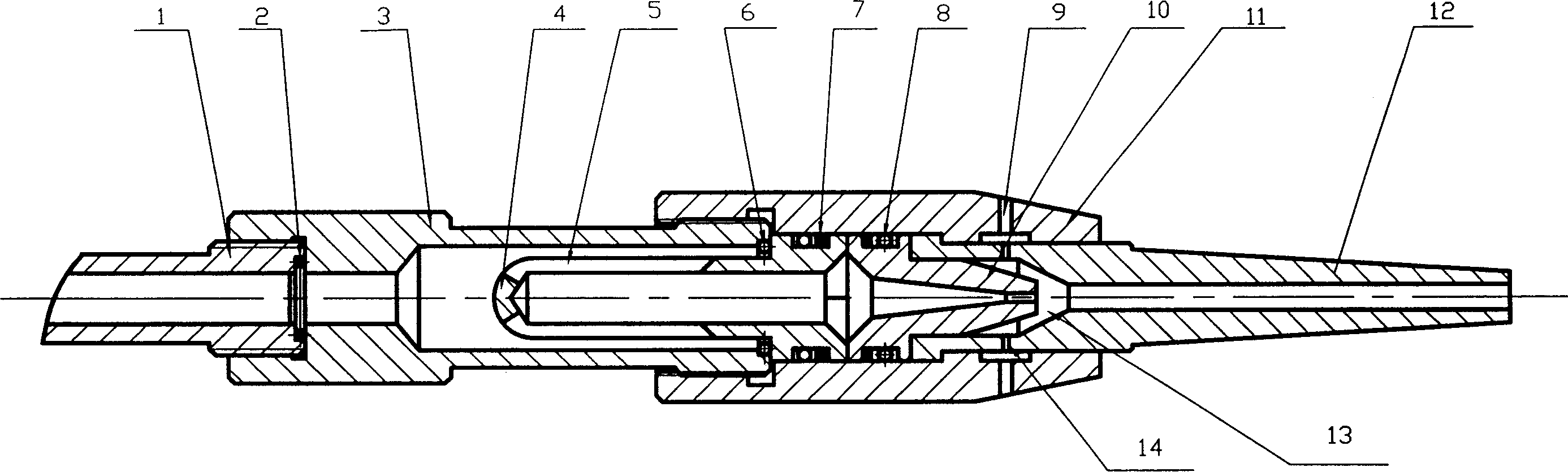

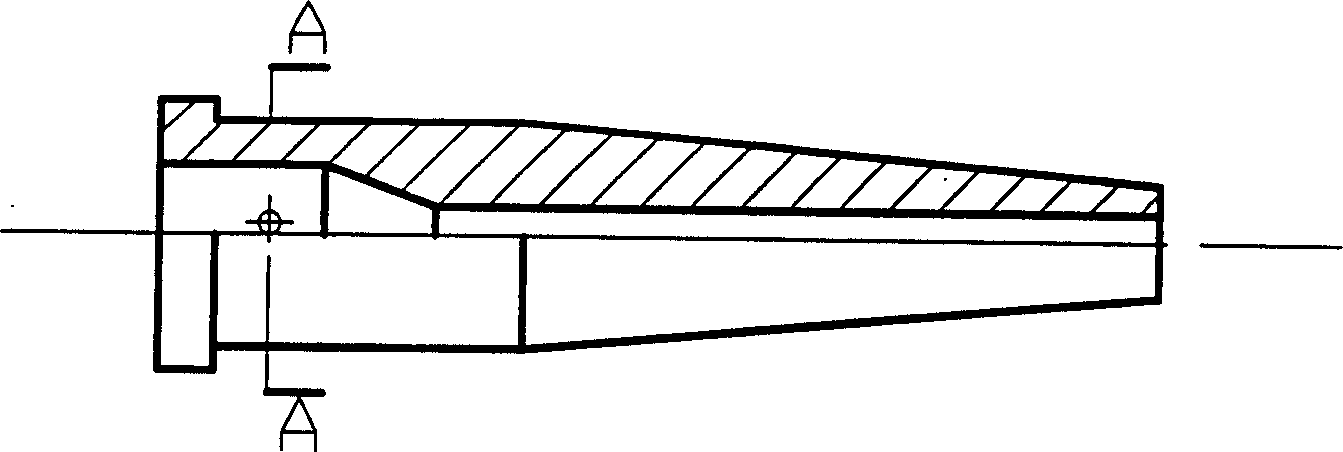

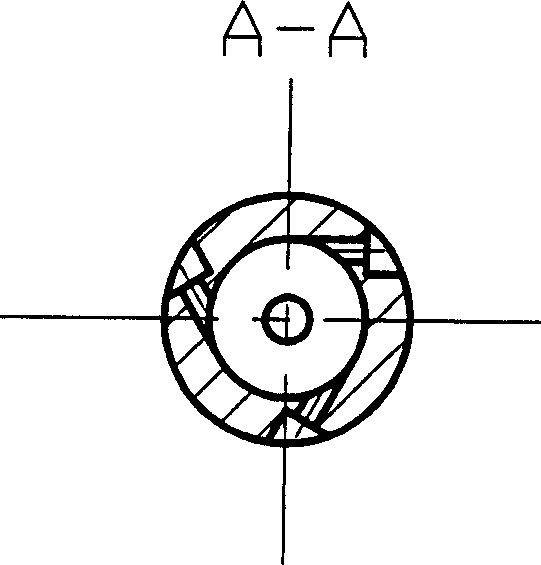

[0018] according to Figure 1-4 The specific structure and working process of the present invention will be described in detail. The device includes a spray rod 1 connected with a high-pressure rubber hose, a locking rod 3, a rectifying grid 4 with a grid hole 5, a conical convergent nozzle 10, sealing rings 2, 6, 8, retaining ring 7, and a collimating tube 12 And nozzle body 11 and other components. Wherein the nozzle body 11 is connected with the locking rod 3 and the spray rod 1. The rectifying grid 4 , the conical convergent nozzle 10 and the collimator 12 are assembled in the shower head body 11 by using the seal assembly sealing ring 8 and retaining ring 7 . The collimating tube 12 is fixed on the front end of the conical converging nozzle 10, and a cavity 13 is formed between the outer cone of the conical converging nozzle 10 and the inner cone of the collimating tube 12. The cavity 13 passes through the suction on the collimating tube 12. The gas hole 14 and the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com