Steam circulation device of microwave heating garbage treatment equipment

A technology of garbage disposal and microwave heating, used in lighting and heating equipment, solid waste removal, combustion methods, etc., can solve the problems of no moisture and odor removal, difficult application, troublesome operation, etc., to eliminate odor components, reduce Odor intensity, effect of shortening treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

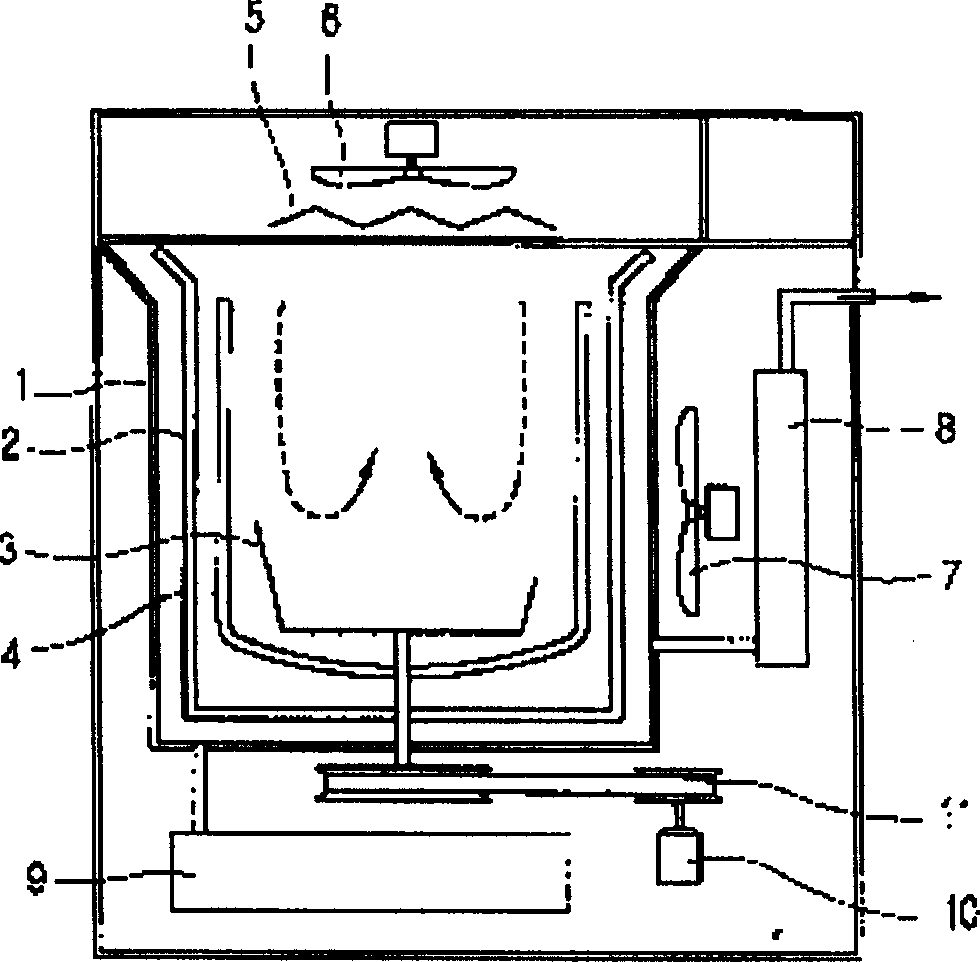

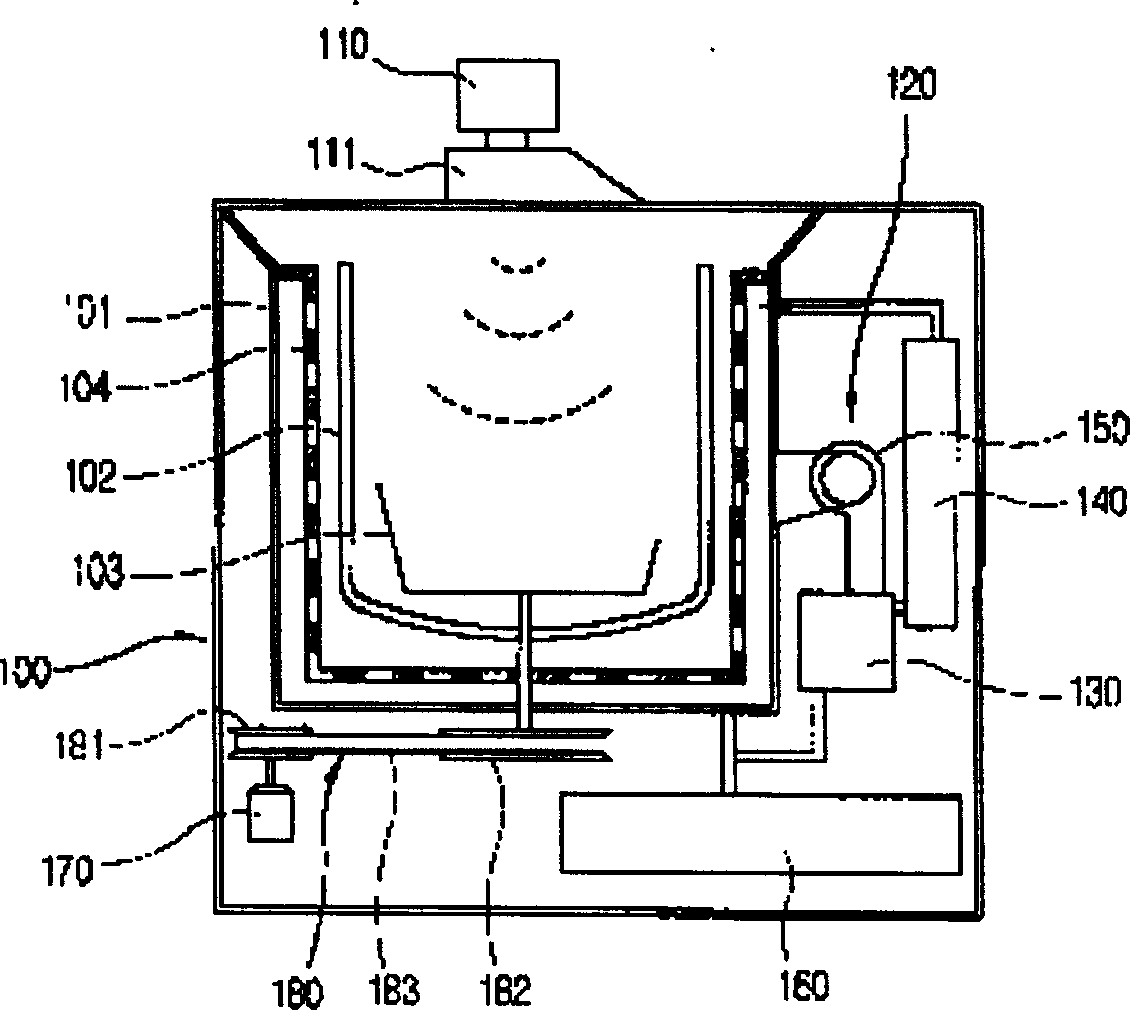

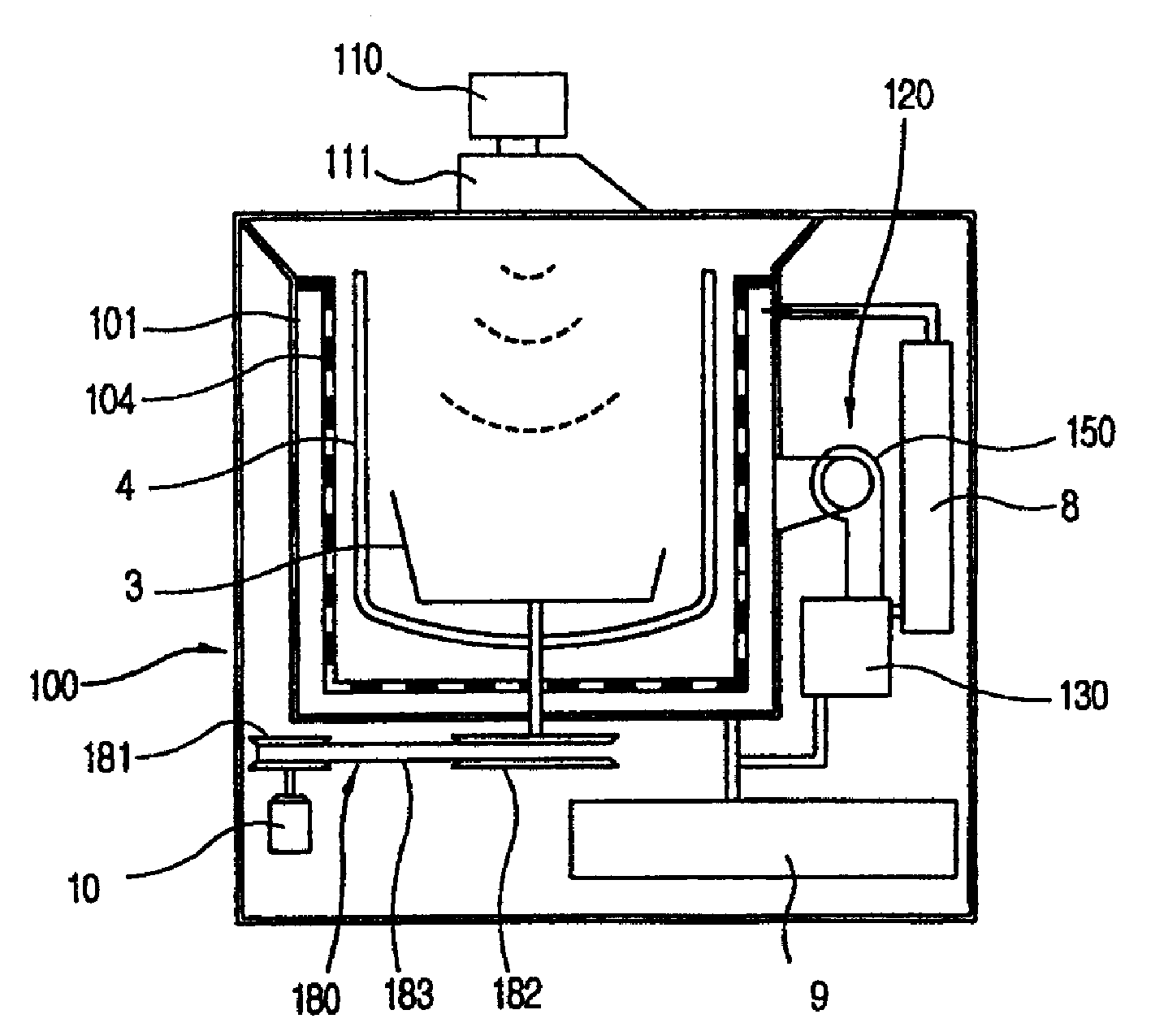

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: figure 2 It is a longitudinal sectional view of the garbage disposal apparatus of this invention. As shown in the figure, the main body 100 constitutes the appearance of the treatment device, and the inside of the main body 100 is provided with a treatment tank 101; the inside of the treatment tank 101 is provided with a container 4 for carrying waste; the inside of the container 4 is provided with an agitator 3, and the agitator 3 Can be rotated.

[0031] The upper part of the treatment tank 101 is provided with a magnetron 110 and a waveguide 111, the magnetron 110 generates microwaves to dry the treated matter, and the waveguide 111 guides the movement of the microwaves; the inside of the treatment tank 101 is provided with a microwave blocking perforated plate 104, The microwave blocking perforated plate 104 blocks microwaves and allows wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com