Valve stem sealing component for IC engine

A technology for valve stems and internal combustion engines, which is applied in the direction of engine sealing, engine sealing devices, engine components, etc., and can solve problems such as unsatisfactory implementation forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

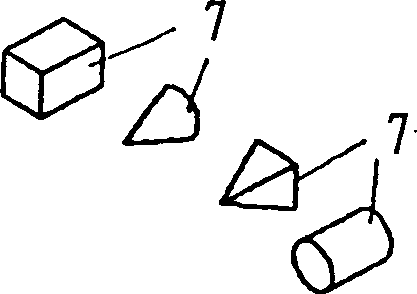

[0014] The valve stem seal 1 consists of a support element 2 made of sheet metal, to which a sealing element 3 is fastened. The sealing element 3 is made of polymer material. It has a static seal 4 with a ring-shaped lug, with which the sealing element is placed on the valve stem guide, not shown, and the sealing element 3 has a sealing lip 5 at its upper end, which is attached to the valve in the assembled state. on the pole. Furthermore, the sealing lip 5 can also be compressed by means of an annular clamping spring 6 . On the sealing lip 5 there are a large number of projections 7 whose inner diameter is smaller than the inner diameter of the sealing lip 5 when viewed relative to the valve stem axis. The protrusions 7 can be sprayed (injected) on the sealing lip 5 individually, or directly pressed together. They can consist of a less wear-resistant material than the sealing lip 5 and / or of the same material as the sealing lip.

[0015] The protrusions 7 may be conical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com