Waveform controller for vibro-bench

A technology of control unit and control method, applied in the direction of automatic control, automatic control, automatic controller, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. However, these examples do not limit the technical scope of the present invention. Incidentally, in the drawings, descriptions are given by attaching the same reference numerals or characters to the same similar objects.

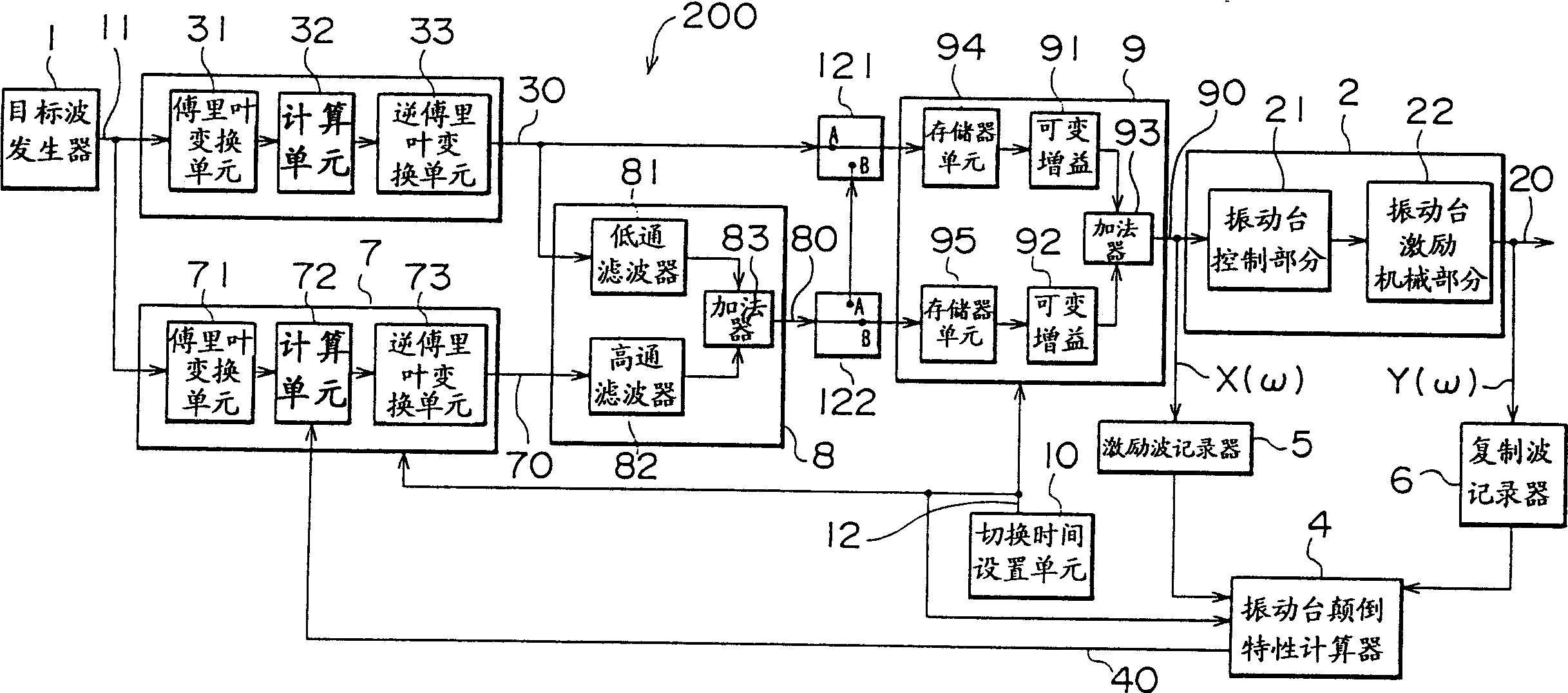

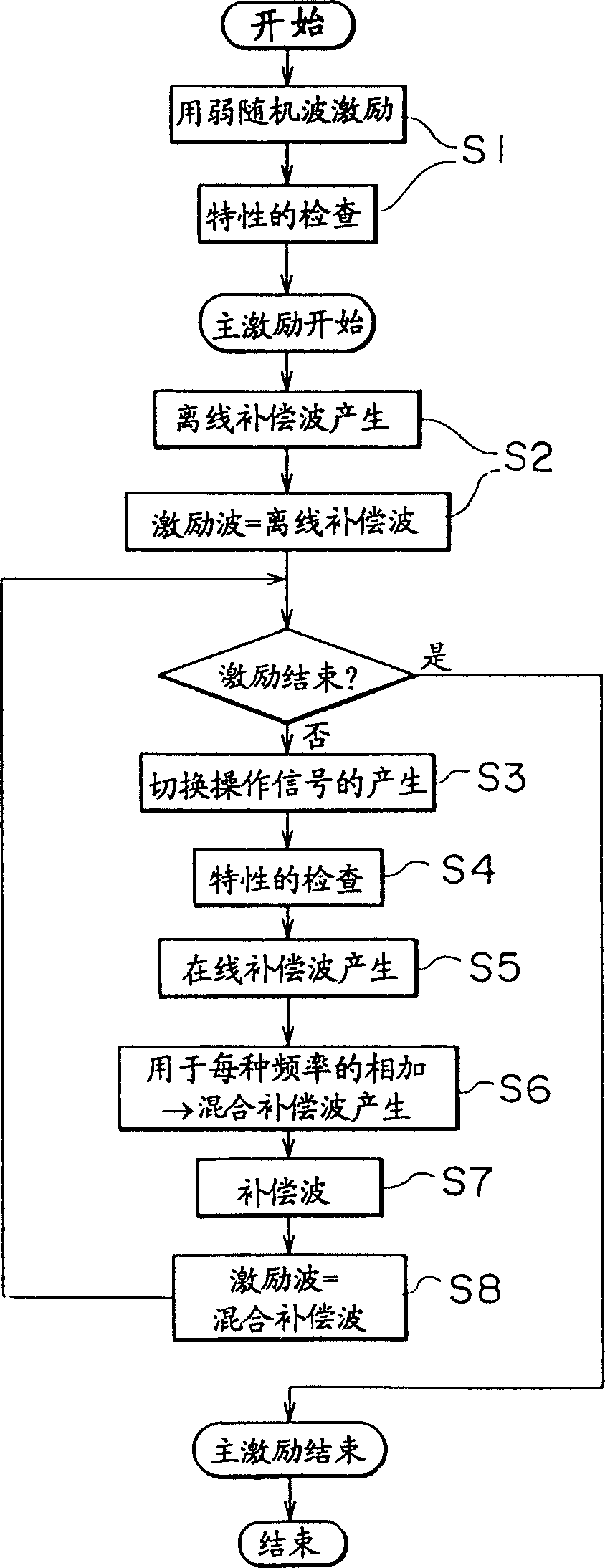

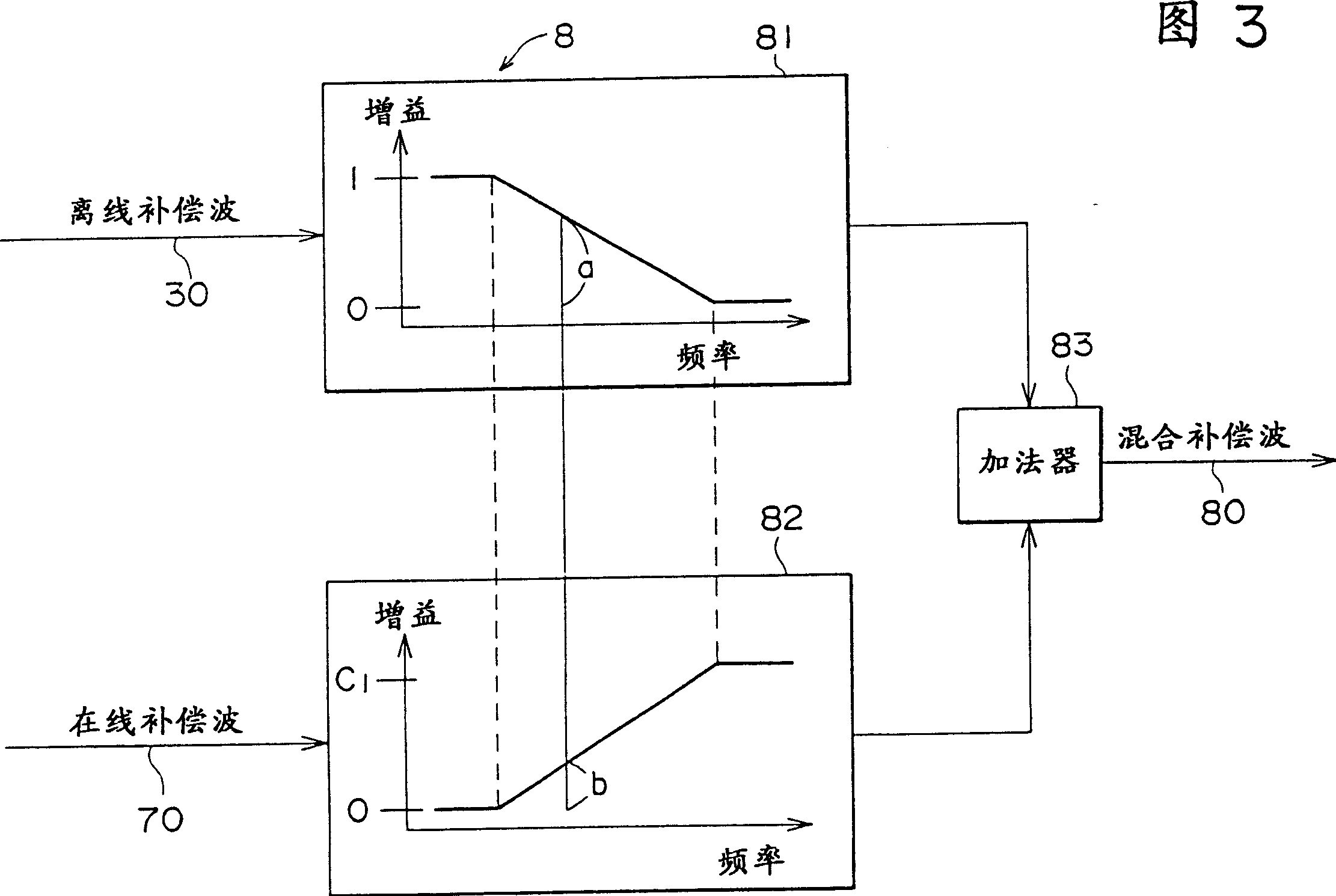

[0047] figure 1 is a block diagram showing a first embodiment of the waveform control unit to which the present invention is applied. A waveform control unit 200 according to the first embodiment of the present invention is a unit in which, for each time, the excitation period preset before the excitation, determines the inverse characteristic of the vibrating table at that time, and switches the excitation wave to This inverse characteristic produces a compensating wave. That is, it is a unit in which on-line compensation is performed at each setting moment during excitation.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com