Cross-flow filter function possessed filter device and operation method

A cross-flow filtration and filtration device technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of increasing pressure difference, continuous operation of the device, exceeding the set value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

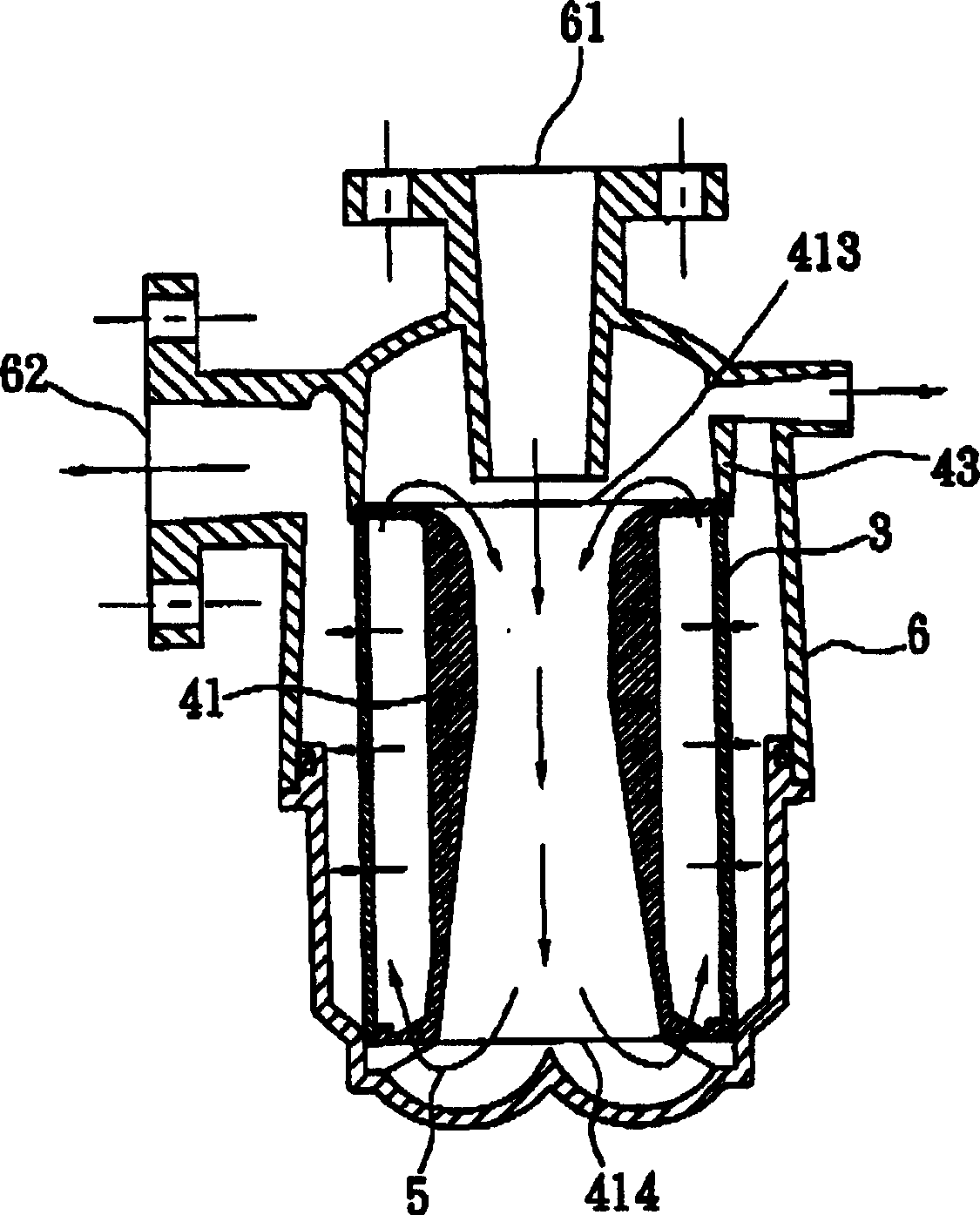

[0035] The present invention will be described in detail below with specific examples in conjunction with the accompanying drawings, so as to have a deeper understanding of the present invention.

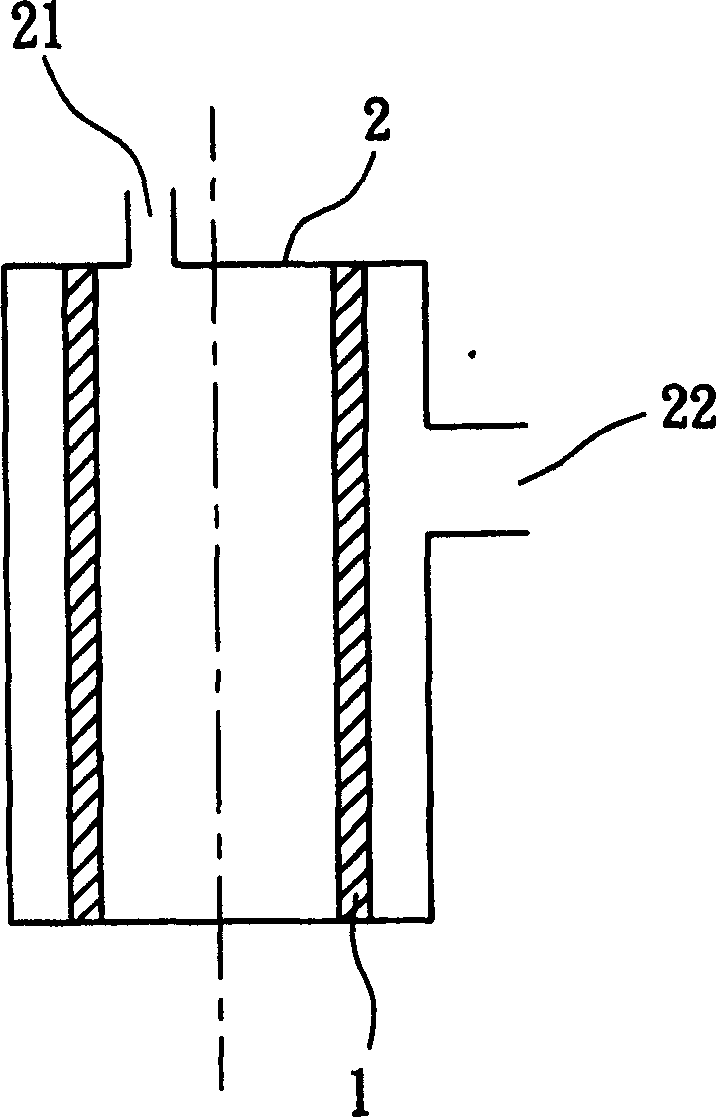

[0036] The present invention proposes a filter device with cross-flow function, especially a filter device capable of generating cross-flow so that filter cakes are not easily produced on the filter. Its structure is simple, and it can increase the effective operating time of the filtering device, and can operate continuously without stopping.

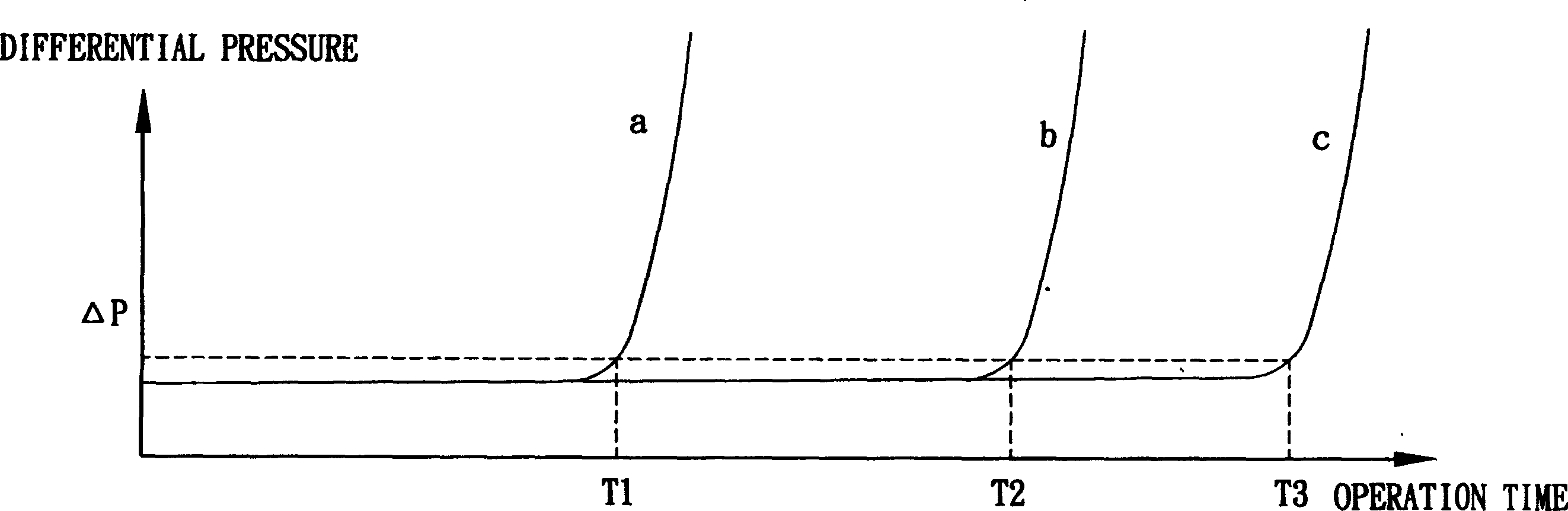

[0037] According to Darcy's Law: J≡(1 / A)(dV / dT)={Δp / [η*(Rm+Rc)]}

[0038] J: filtrate flux (permeate flux)

[0039] A: effective surface area of filter media

[0040] V: total volume of filtrate (total volume of permeate)

[0041] T: Filtration time

[0042] Δp: Pressure drop imposed across the cake and filter media

[0043] η: filtrate viscosity (viscosity of the permeate)

[0044] Rm: resistance of the filter media

[0045] Rc: re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com