System and method for purifying crude caprolactam water solution

A technology of crude caprolactam and caprolactam, which is applied in the field of equipment for purifying crude caprolactam aqueous solution, and can solve problems such as high consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The purpose and effects of the present invention are described in detail below by means of examples.

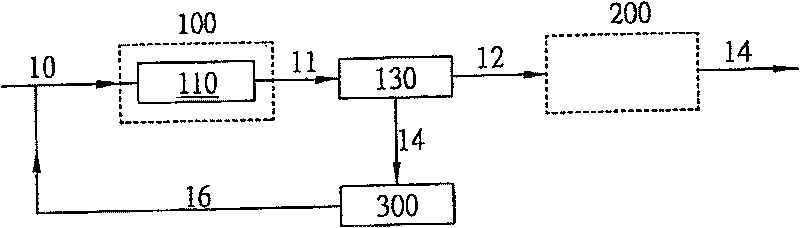

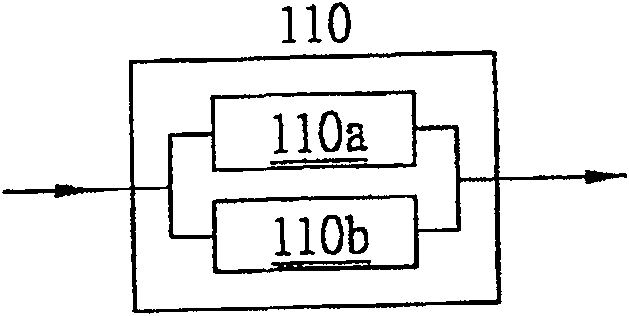

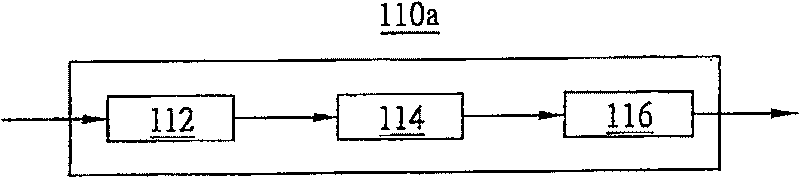

[0034] Figure 1A Example 1 of the present invention will be described. The equipment of the present invention includes a filter area 100, a detection unit 130, a purification area 200, and a first temporary storage device 300. A resin filter device, such as an ion exchange resin device group 110, is arranged in the filter area, and the crude oil is removed by resin adsorption and filtration. Ionic impurities in caprolactam aqueous solution to form filtered caprolactam aqueous solution. The crude caprolactam aqueous solution containing 30 to 40% lactam, water, and impurities generated by the Beckmann rearrangement reaction is introduced into the filter area 100 through the pipeline 10, and the ion exchange resin device group 110 located in the filter area 100 is used for resin filtration. Ionic impurities in the crude caprolactam aqueous solution are removed to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com