Method and device for prolonging sequencing-batch membrane bioreactor membrane service life

A sequencing batch membrane biology and reactor technology, applied in biological treatment devices, chemical instruments and methods, biological water/sewage treatment, etc., can solve cumbersome operating procedures, high process investment and operating costs, increase equipment investment and operation Manage costs and other issues to achieve the effect of reducing cleaning frequency, saving investment and operating costs, and extending effective operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

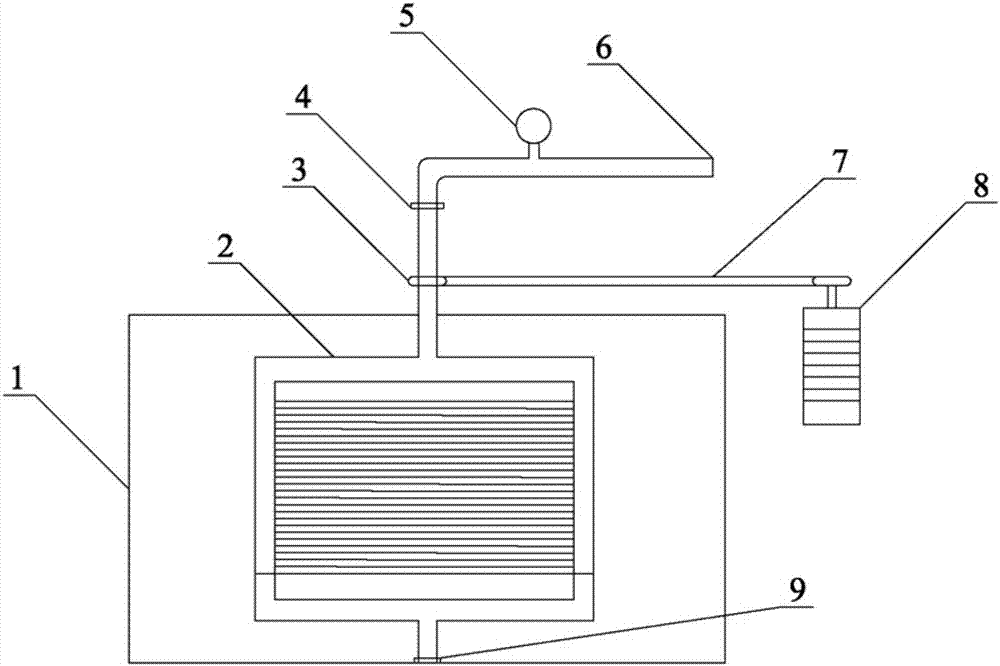

[0030] The upper end of the membrane module 2 is equipped with a sealed and fixed rotating sleeve 4, and the lower end is installed with a fixed rotating sleeve 9, and the sealed and fixed rotating sleeve 4 is used to realize that the suction pipe in the lower half rotates with the membrane module 2, and the suction pipe in the upper half is fixed. This structure enables the membrane module 2 to maintain an internal vacuum state when pumping water, while the membrane module 2 can rotate freely; the fixed rotating sleeve 9 is fixed at the bottom of the reactor, which can satisfy the free rotation of the membrane module 2; its transmission disc 3 passes through the transmission belt 7 is connected with the motor 8, and the motor 8 drives the membrane module 2 to rotate, and the number of revolutions of the membrane module 2 is the same as that of the motor 8.

[0031] When the motor 8 is working, the transmission belt 7 drives the membrane module 2 to rotate at a speed of 20r / min...

Embodiment 2

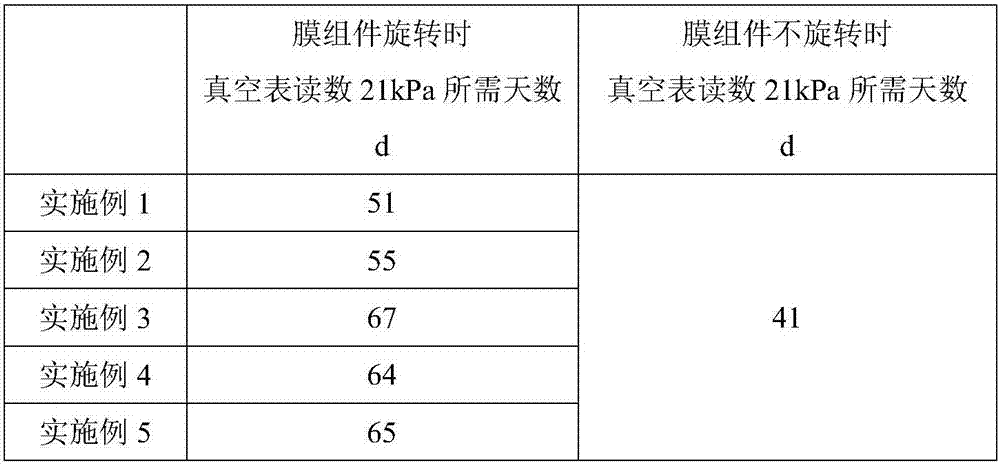

[0033] Its device structure is identical with embodiment 1. When the motor 8 is working, the transmission belt 7 drives the membrane module 2 to rotate at a speed of 40r / min, clockwise and counterclockwise alternately and intermittently, the intermittent time is 10s, and the rotation time is 2.5min, so as to reduce membrane fouling , The purpose of increasing the service life. When the reading of the vacuum gauge 5 reaches 21kPa, the membrane module 2 needs to be cleaned.

Embodiment 3

[0035]Its device structure is identical with embodiment 1. When the motor 8 is working, the transmission belt 7 drives the membrane module 2 to rotate at a speed of 60r / min, clockwise and counterclockwise alternately and intermittently, the intermittent time is 15s, and the rotation time is 3min, so as to slow down the membrane fouling, The purpose of increasing the service life. When the reading of the vacuum gauge 5 reaches 21kPa, the membrane module 2 needs to be cleaned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com