Rotor spinning machine

A rotor spinning machine and spinning unit technology, applied in spinning machines, open-end spinning machines, continuous winding spinning machines, etc., can solve problems such as poor joint quality, and achieve improved joint quality and precision The effect of request reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

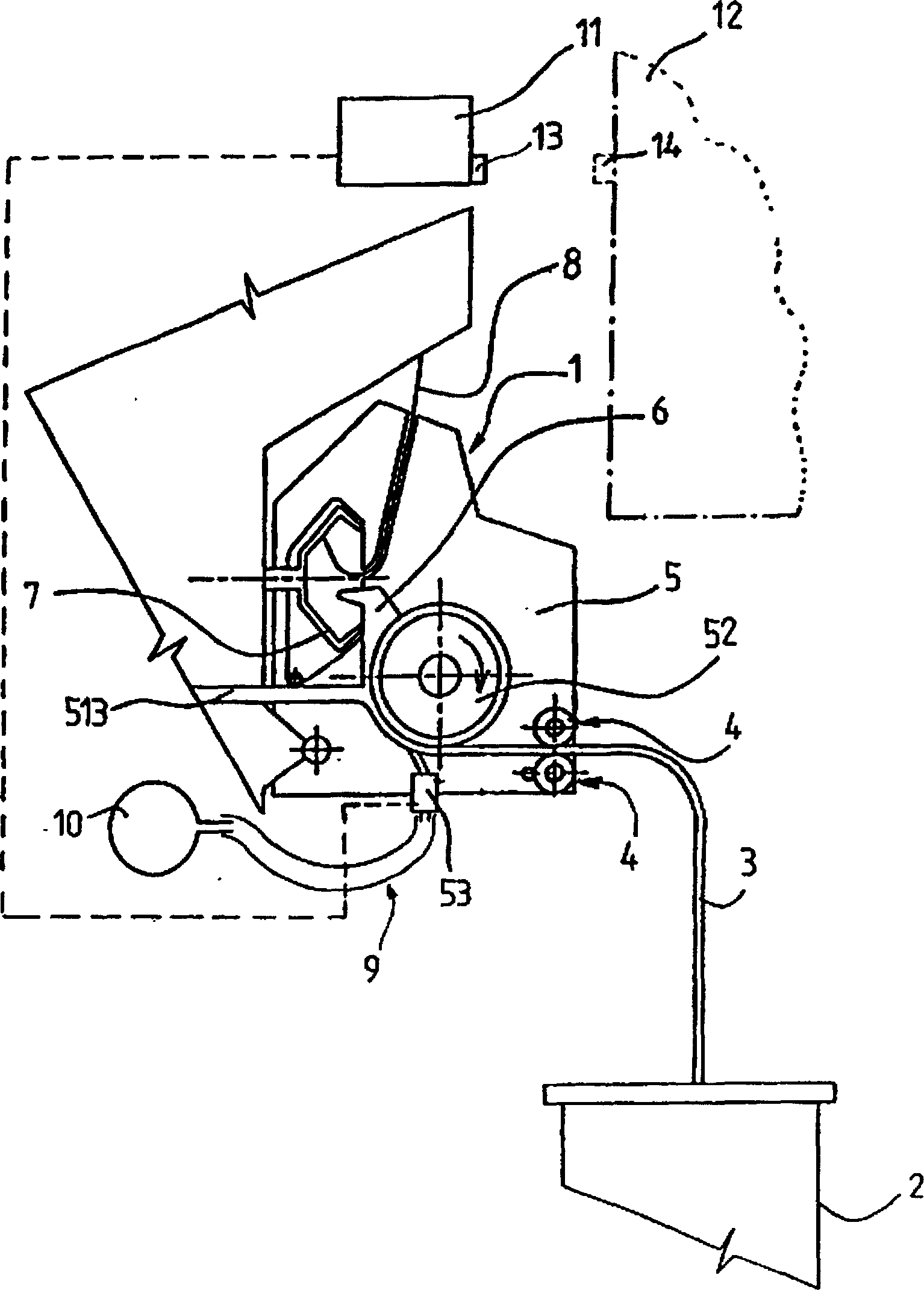

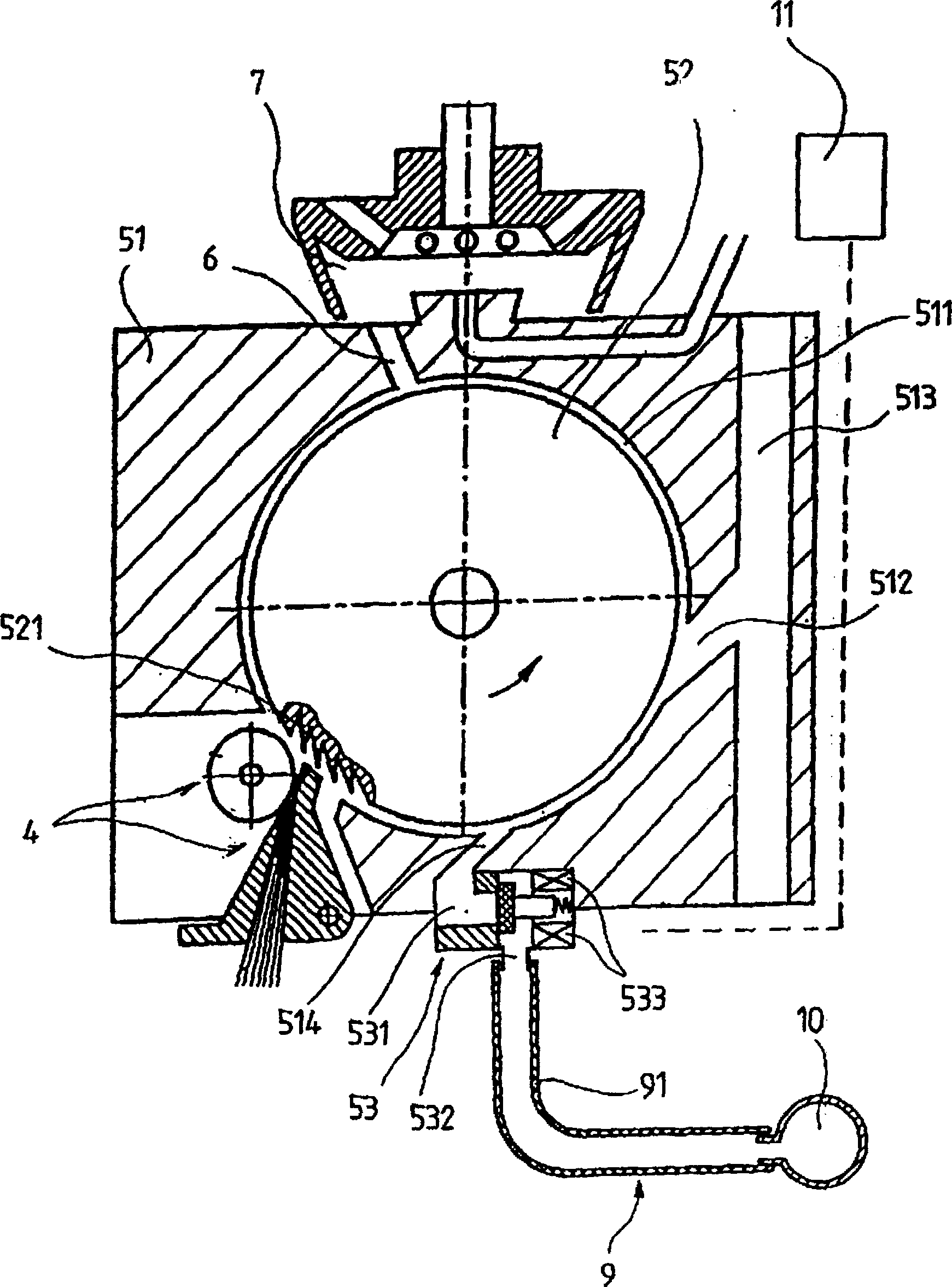

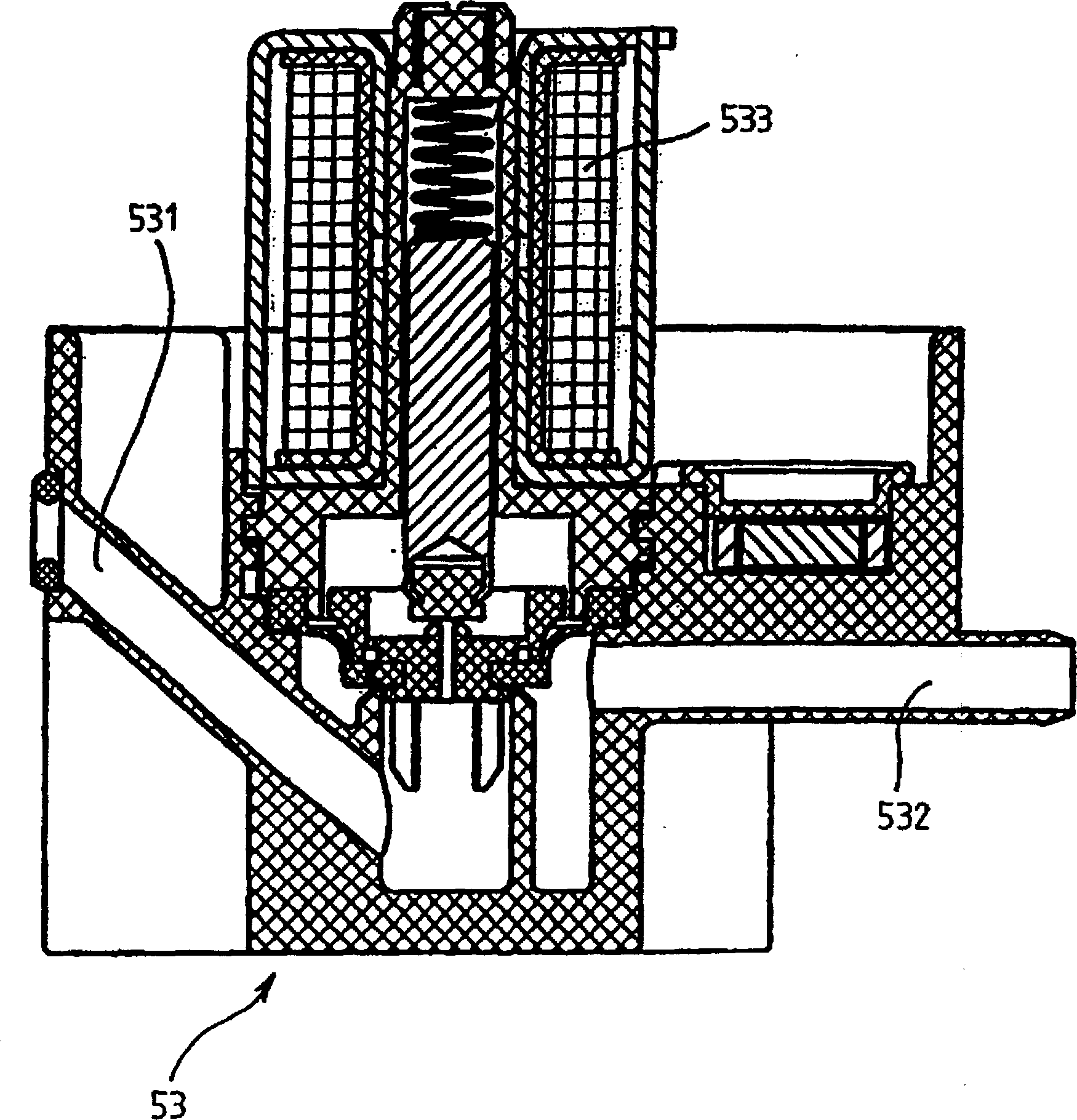

[0017] A rotor spinning machine has several operating units arranged side by side. Each operating unit produces yarn from a sliver of textile fibers and winds it up on bobbins.

[0018] Rotor spinning machines are made fully automatic or semi-automatic; the invention cannot be used on spinning machines controlled only by humans.

[0019] The fully automatic rotor spinning machine is equipped with a supervisory device which can be adjusted along the operating unit of the rotor spinning machine and in the operating unit when spinning is to be restarted and / or when a full bobbin is replaced with an empty tube. A device for monitoring operations.

[0020] The semi-automatic rotor spinning machine is partly supervised manually, and partly equipped with an automatic device for yarn splicing. Associated with each operating unit of a semi-automatic rotor spinning machine is a control unit whose purpose is to control and / or collect data, for which purpose it is connected to the slive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com