Fuel injection pump

A technology of fuel injection pump and fuel inlet, which is applied in the direction of fuel injection pump, fuel injection device, fuel injection control, etc., can solve heating and other problems, and achieve the effect of improvement, small pressure loss, and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

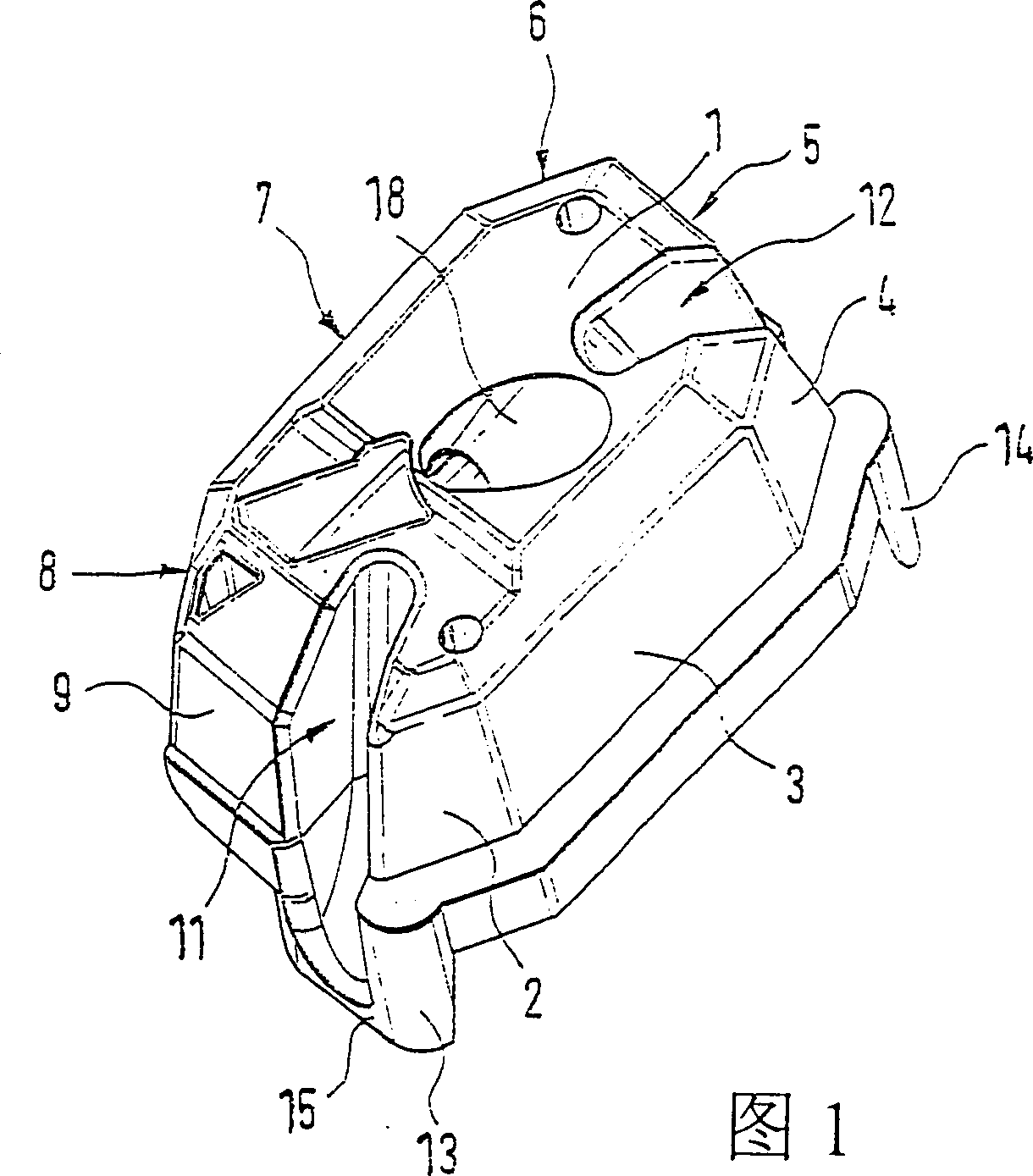

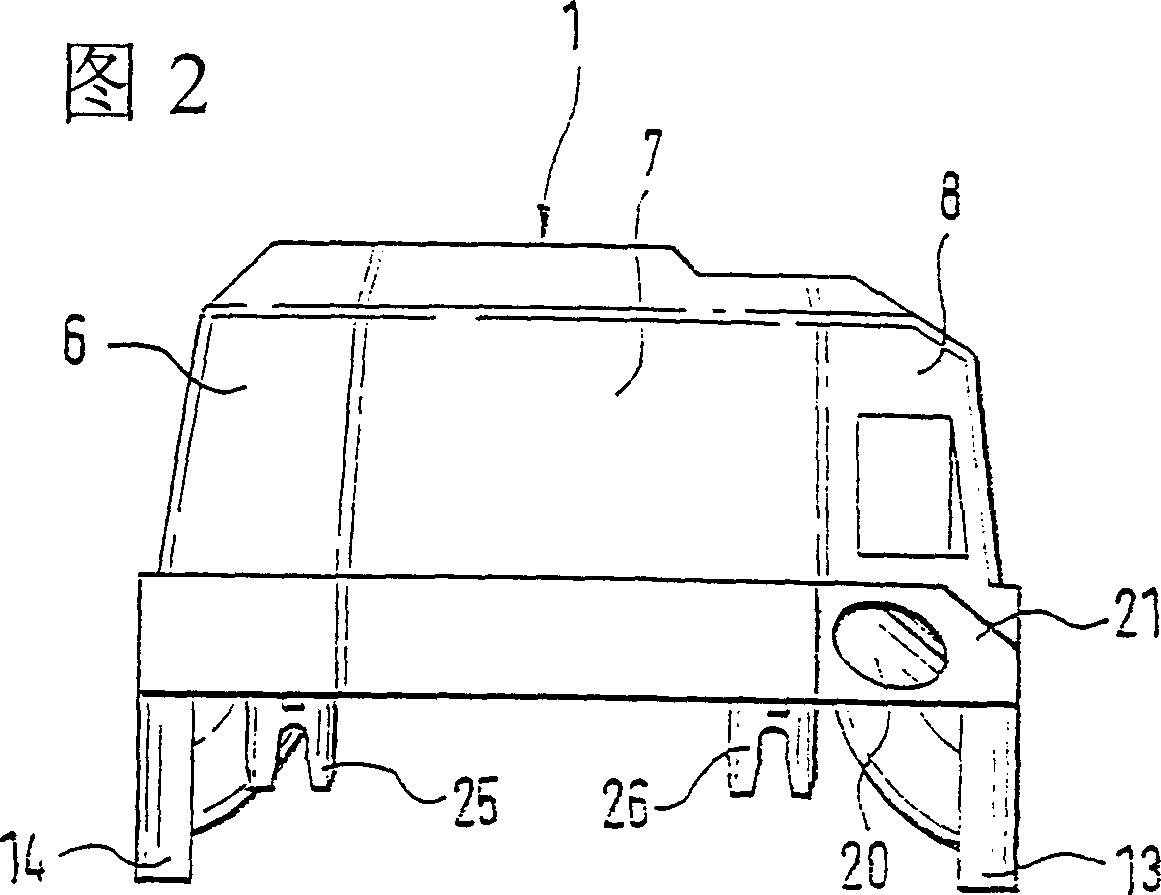

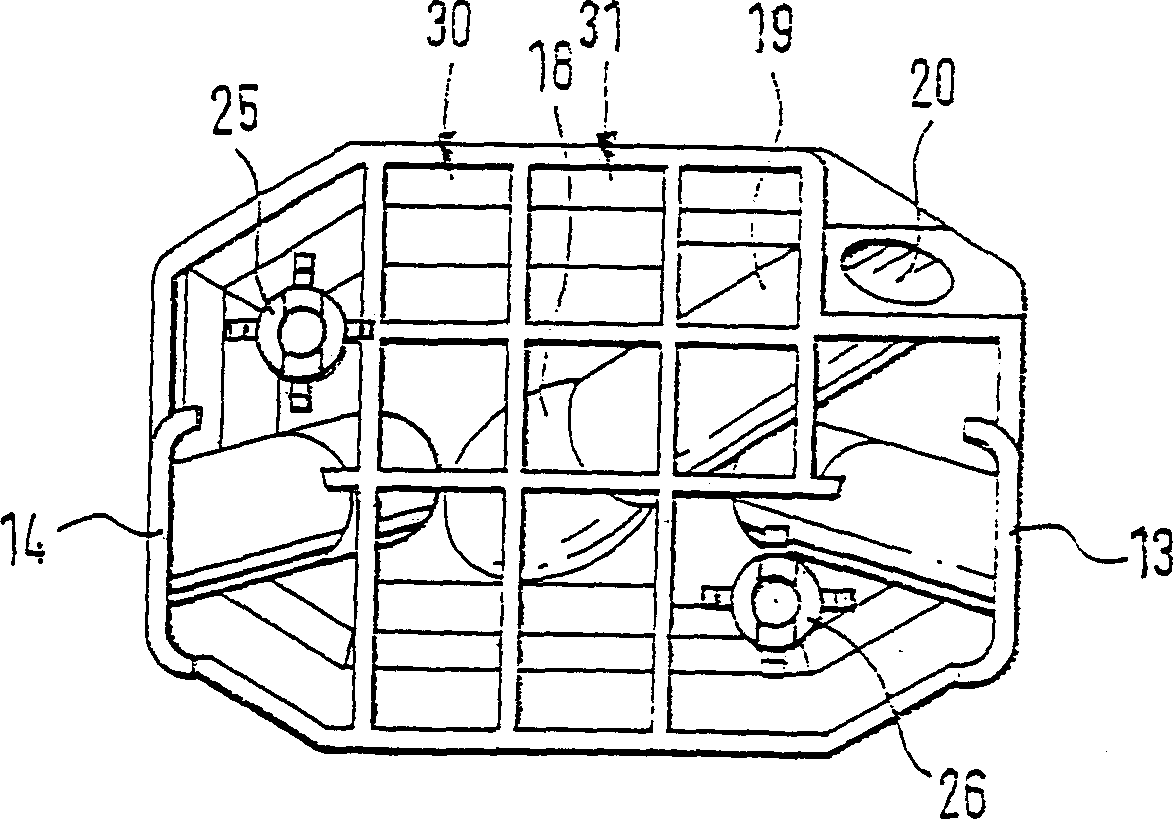

[0018] The filler piece shown in perspective in FIG. 1 is accommodated in a cavity formed between the top side of the pump housing and the bottom side of the control unit housing of a jet pump according to the invention. A fuel inlet opens into the cavity, through which fuel reaches the cavity from a fuel tank. The fuel can either be delivered into the cavity by means of a backing pump, or it can be sucked in only by the delivery pump of the jet pump. A connecting line leads from the cavity to the delivery means of the jet pump. The opening for the connecting duct is arranged in the cavity above the opening for the fuel inlet. This achieves that the cavity is always filled with fuel up to a certain level. Inevitably in operation, there will also be a certain amount of air in the cavity. The lower part of this cavity is bounded by the pump housing of the jet pump. However, the upper part of the cavity is bounded by the bottom of the control unit housing. The control unit h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com