Palm-based artificial graphite and preparation method thereof

An artificial graphite and palm-based technology, applied in chemical instruments and methods, petroleum industry, inorganic chemistry, etc., can solve the problems of cumbersome process, low degree of graphitization, high production cost, etc., achieve good magnification, high degree of graphitization, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

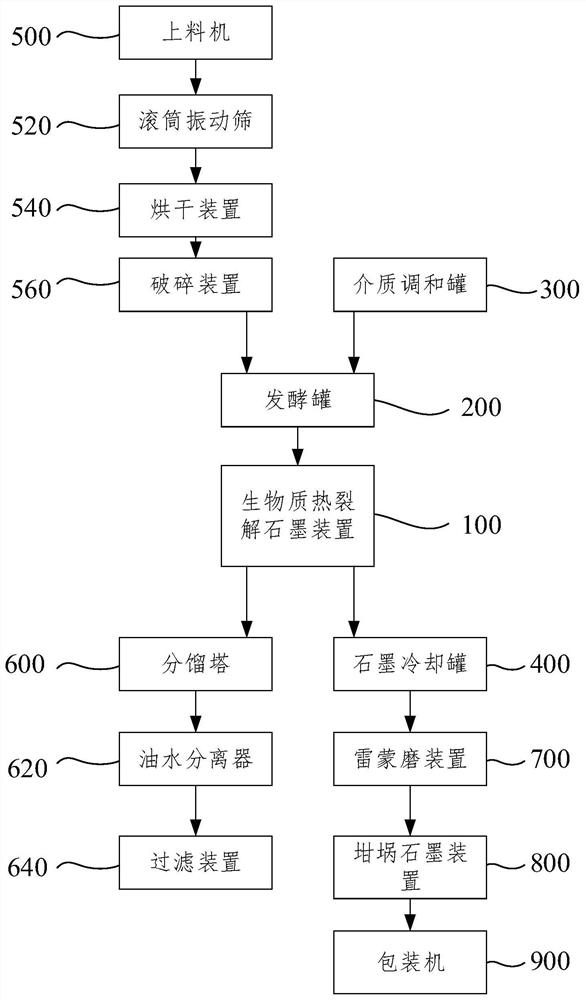

[0051] A kind of preparation method of palm-based artificial graphite comprises the steps:

[0052] Step 1. The palm-based body is screened through a drum vibrating sieve to remove powder and dust to obtain high-quality palm shell raw materials. The qualified palm-based body is transported into the drying system for drying. The moisture contained in the palm-based body 40%-50%, after drying, the water content will be reduced to less than 15%, and the dried palm-based powder will be crushed by a crusher to obtain palm-based powder with a particle size of 0.2-0.8mm.

[0053] Mix asphalt and tire oil at a weight ratio of 1:5, and stir at 80°C-150°C for 1 hour to obtain a mixed liquid of asphalt tire oil.

[0054] Step 2, mixing the palm-based powder and the asphalt tire oil mixed liquid at a weight ratio of 1:1.5 at a temperature of 80°C-150°C for 1h-2h to obtain a mixed material.

[0055] Step 3, fermenting the mixed material together with 0.3% hydrogen peroxide of the mixed ma...

Embodiment 2

[0062] A kind of preparation method of palm-based artificial graphite, this preparation method has following difference with embodiment 1, other is with embodiment 1:

[0063] The concrete steps of described graphitization treatment are as follows:

[0064] Wash the high-temperature graphitization furnace twice, evacuate to a vacuum of 0.1MPa, then fill with argon to atmospheric pressure, evacuate to 0.1MPa, and then fill with argon to slightly positive pressure;

[0065] 100kg of carbonized material is cooled by the cooling system, then passed through particle shaping, and then enters the high-temperature graphitization furnace;

[0066] Under an argon atmosphere with a ventilation flow rate of 5L / min-15L / min, heat up the high-temperature graphitization furnace to 3000°C at a rate of 10°C / min and keep it for 4 hours, then naturally cool down to room temperature to obtain 81.5kg of palm-based artificial graphite . The material loss rate during the graphitization process was ...

Embodiment 3

[0068] A kind of preparation method of palm-based artificial graphite, this preparation method has following difference with embodiment 1, other is with embodiment 1:

[0069] The concrete steps of described graphitization treatment are as follows:

[0070] Wash the high-temperature graphitization furnace twice, evacuate to a vacuum of 0.1MPa, then fill with argon to atmospheric pressure, evacuate to 0.1MPa, and then fill with argon to slightly positive pressure;

[0071] 100kg of carbonized material is cooled by the cooling system, then passed through particle shaping, and then enters the high-temperature graphitization furnace;

[0072] Under an argon atmosphere with a ventilation flow rate of 5L / min-15L / min, heat up the high-temperature graphitization furnace to 3000°C at a rate of 15°C / min and keep it for 5 hours, then cool down naturally to room temperature to obtain 85.2kg of palm-based artificial graphite . The material loss rate during the graphitization process was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com