Logistic dynamic material control process

A dynamic and technological technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of deployment, inability to use resources properly, and uneven job assignment of picking personnel, so as to improve the efficiency of picking materials and the use of personnel. The effect of rate optimization, average workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

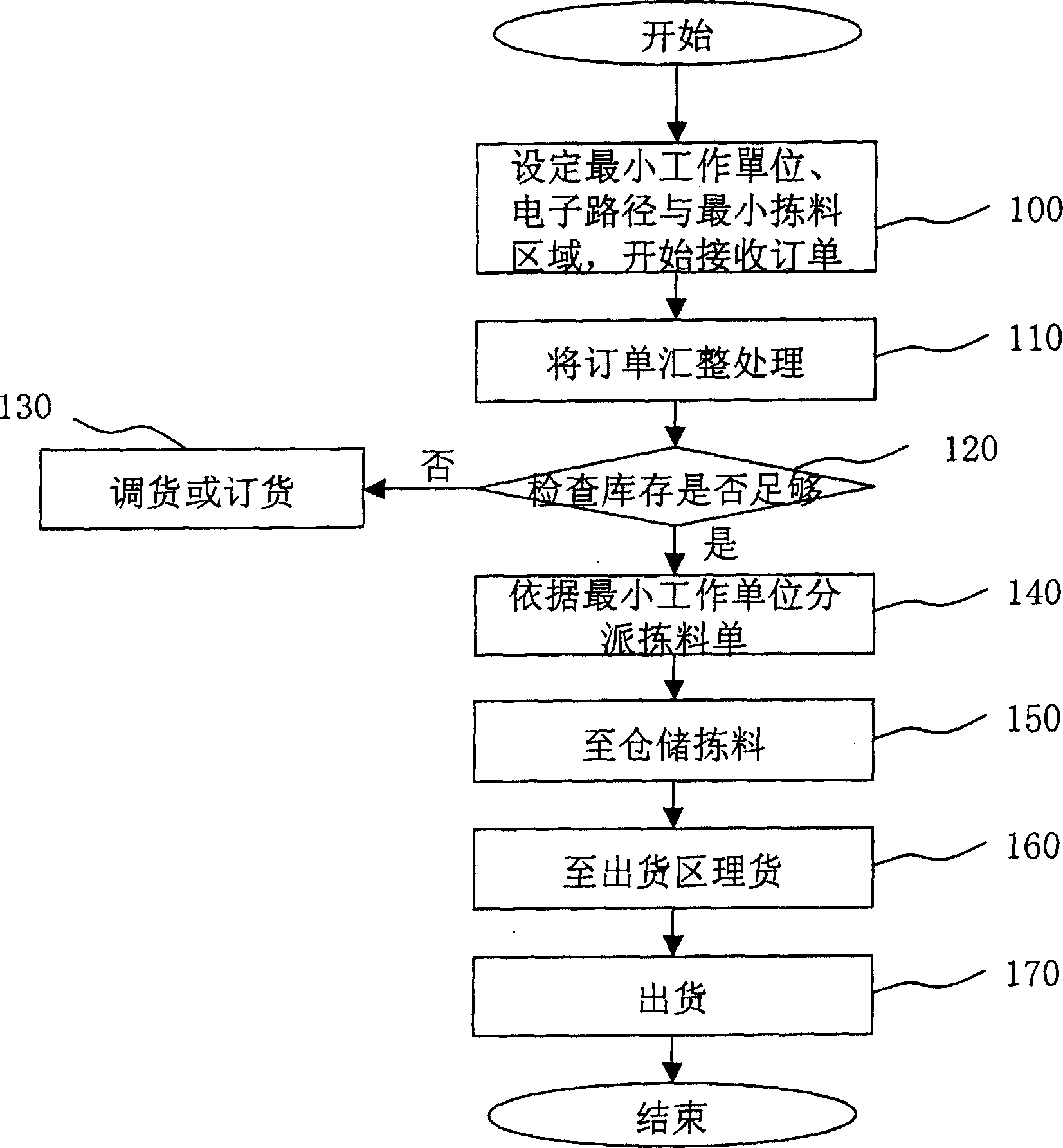

[0029] The present invention illustrates the specific feasibility of the method proposed by the present invention with a preferred embodiment, please refer to figure 1 , this picture is the flow chart of the previous material picking operation, used to illustrate the process of traditional material picking and dispatching, and its description is as follows:

[0030] First, the system will first set the minimum work unit, define all electronic paths and the minimum picking area, and then start receiving orders (step 100), and the warehouse personnel will first collect and process the orders (step 110), and then check whether the inventory Enough (step 120), if the stock is insufficient, then arrange to transfer or order (step 130), otherwise, assign the picking list according to the smallest work unit (step 140), after the picking personnel get the picking list, they go to the warehouse to pick Material (step 150), after the picking work is completed, then go to the shipping ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com