Integrated cogeneration system beverage mfg. system

A production system and beverage technology, applied in climate change adaptation, direct carbon dioxide emission reduction, machine/engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

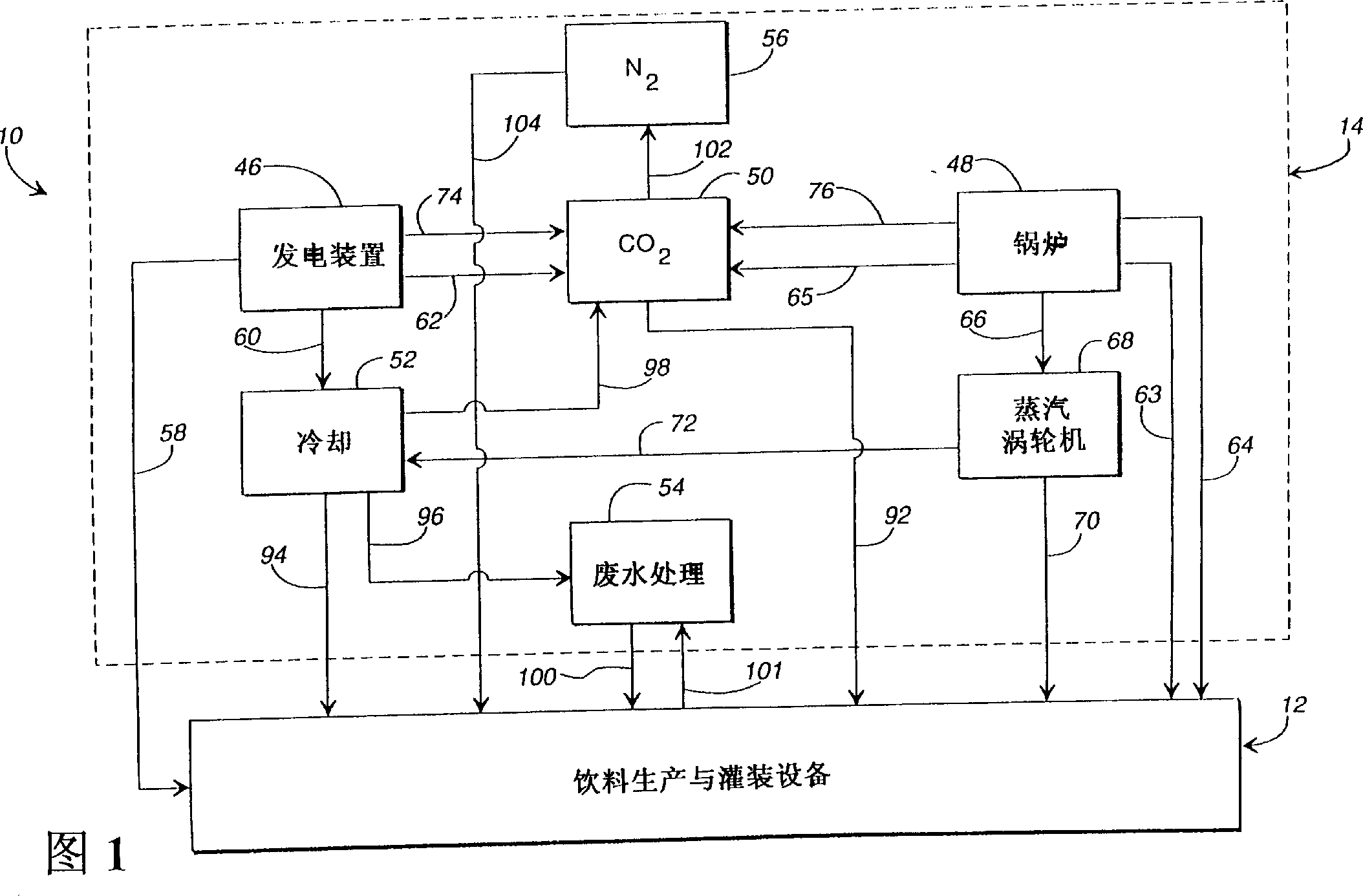

[0024] As outlined above, the present invention includes an integrated co-production system, a method of providing such a co-production system at the point of beverage production, and the use of such a co-production system in a beverage production system. A beverage production system including an integrated collaborative production system according to an embodiment of the present invention is described in detail below.

[0025] 1 shows a beverage production system 10 according to an embodiment of the present invention, which includes a carbonated beverage production and filling device (hereinafter referred to as a beverage filling device) 12 directly supported by an adjacent collaborative production system 14 . The co-production system 14 provides various products for the filling facility 12 .

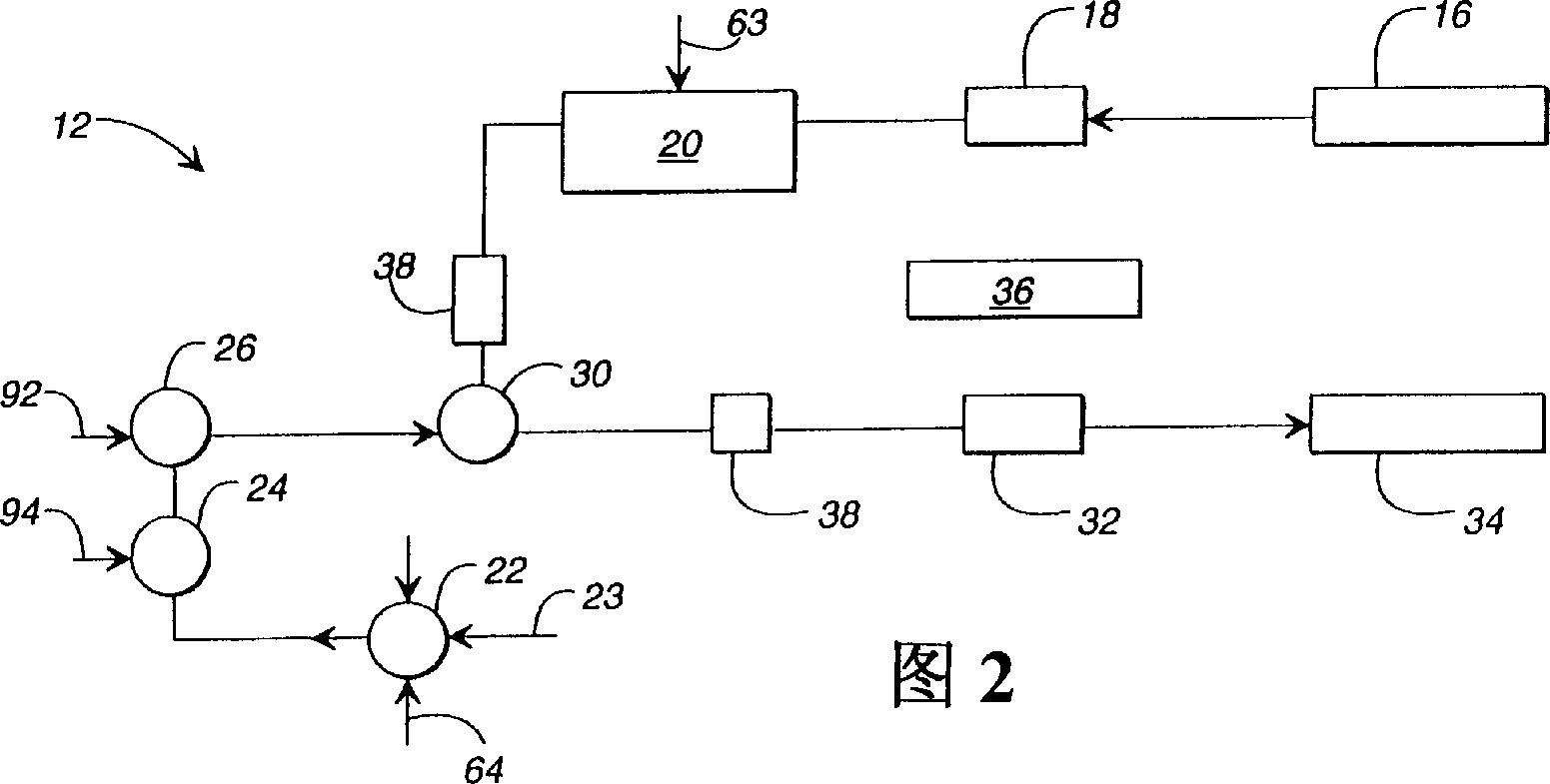

[0026] Carbonated beverage filling equipment and other types of beverage production equipment are well known. Components of the carbonated beverage filling apparatus 12 are shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com